Fuel Line Protector For Superchargers

#21

Posted 13 November 2011 - 09:34 PM

#22

Posted 13 November 2011 - 09:37 PM

oh and its taken me ages to make two. The jig to get the bend right took bloody ages too. So I may take some persuasion to make anymore.

(but thats why there are lots of pics here

)

I also rather over specified the aluminium (5251) so its rock hard. On Lee's car, the one on which the guard is mounted in the above pics, if you try to move the guard the engine moves first.

Let me know how much persuading you need. lol

As it's got to be easier than moving the fuel lines. Would also need to check that the mechanic has already made something, but I doubt it as my car is in no hurry no go anywhere at the mo.

#23

Posted 13 November 2011 - 09:51 PM

So you do it all in your garage! Fair play, I always assumed you must have access to a machine shop or something!Where do you get your materials from?

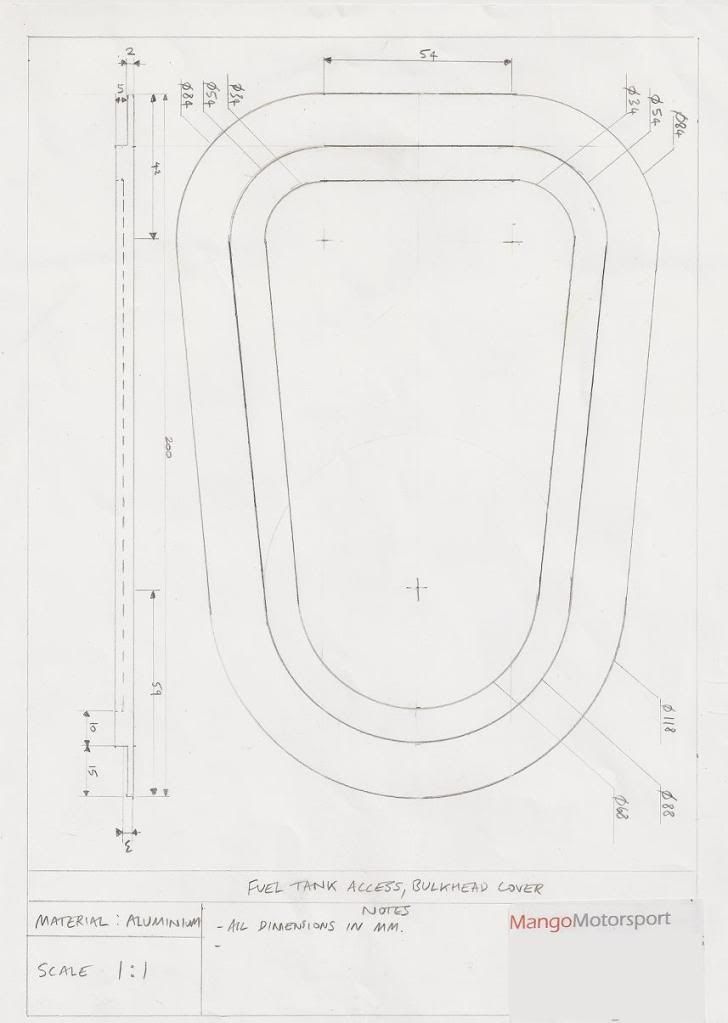

sorry missed this earlier Chris, I tend to get materials from a variety of sources. The local aluminium fabricators let me go through their off-cuts for beer money (usually a 10er at a time), Aluminium warehouse http://www.aluminiumwarehouse.co.uk provided what I wanted for this little project, and Mango has a few contacts now too especially for tools.

#24

Posted 13 November 2011 - 09:58 PM

#25

Posted 13 November 2011 - 10:08 PM

#26

Posted 13 November 2011 - 10:11 PM

you still need to move the fuel linesAs it's got to be easier than moving the fuel lines.

JG's lovely shield just protects the fuel pipes from a failing drive belt

#27

Posted 13 November 2011 - 10:17 PM

#28

Posted 13 November 2011 - 10:24 PM

#29

Posted 13 November 2011 - 10:29 PM

#30

Posted 13 November 2011 - 10:32 PM

Top job JG.

Let me know if you do go into production. I'd considered a kevlar shield but yours is top drawer!

I must admit i did wonder if someone could replicate it in CF? At least the main section, the fixings can be left as they are.

#31

Posted 13 November 2011 - 10:36 PM

#32

Posted 13 November 2011 - 10:39 PM

#33

Posted 13 November 2011 - 10:51 PM

#34

Posted 14 November 2011 - 10:19 AM

#35

Posted 14 November 2011 - 10:36 AM

#36

Posted 14 November 2011 - 11:17 AM

#37

Posted 14 November 2011 - 11:24 AM

#38

Posted 14 November 2011 - 11:30 AM

#39

Posted 14 November 2011 - 08:33 PM

#40

Posted 14 November 2011 - 09:09 PM

2 user(s) are reading this topic

0 members, 2 guests, 0 anonymous users