Fuel System Overhaul

#41

Posted 09 July 2012 - 11:52 AM

#42

Posted 09 July 2012 - 03:16 PM

Top Tip , if you google search for something like this do it also as a "Image" search can save loads of time

Edited by NickB777, 09 July 2012 - 03:18 PM.

#43

Posted 09 July 2012 - 03:22 PM

http://www.conceptra...rol-swirl-pots/ you can get thiese with bolt on fitting to attach to the fire wall

Top Tip , if you google search for something like this do it also as a "Image" search can save loads of time

Great find, the bottom one on that page looks like a winner. Will have to do some proper thinking about fittings sizes now though!!

#44

Posted 09 July 2012 - 03:27 PM

#45

Posted 09 July 2012 - 03:34 PM

http://www.ebay.co.u...=item4167420b4c

there are a few on ebay baulkhead mounted, 1, 1.5lt units I have a 1.5lt one

#46

Posted 09 July 2012 - 04:28 PM

Sizes

Body - 100 mm diameter

Height - 200 mm excluding bleed

Inlets – JIC - 6

Outlet – JIC -8

Bleed – JIC-3

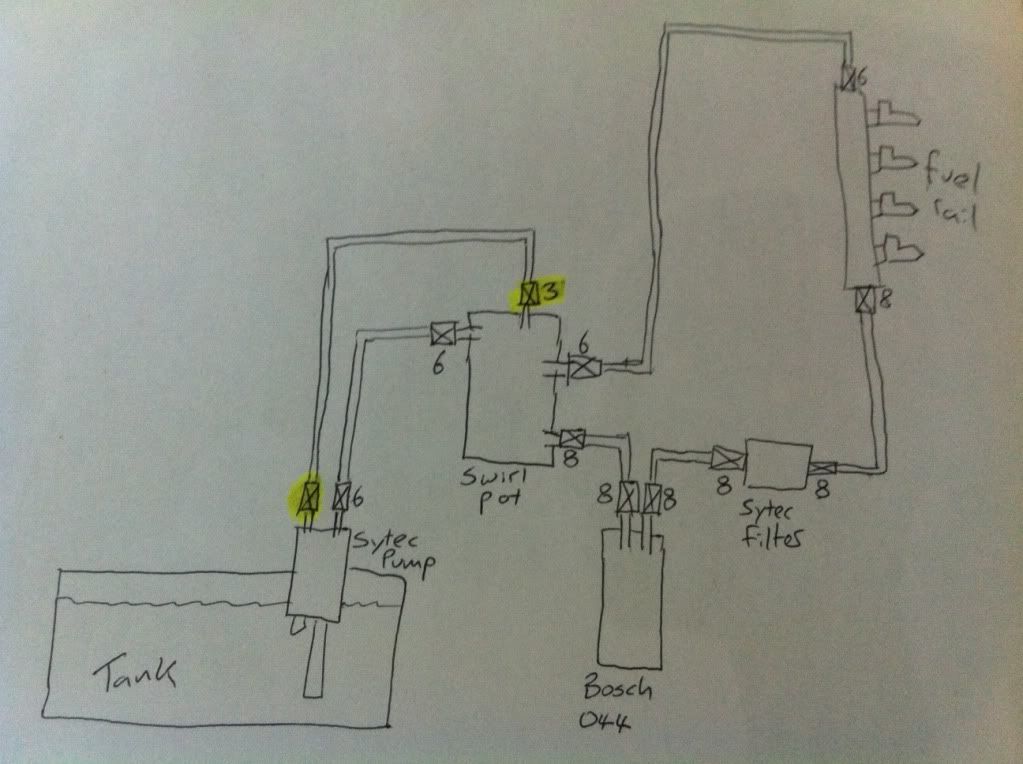

This has led to me trying to plan out all the correct fittings that I will need, hence the sketch below. The part that is troubling me is the return to the tank (from swirl pot to Sytec pump). I've highlighted it in the drawing. As it says in the spec above the bleed is AN3.... I'm worried this is too restrictive as currently most of the guys who've done the fuel line swap have used AN6.

Also where does the standard fuel filter go?

Note numbers refer to AN sizes of fittings/hose

As always guys please join in if you have anything to say

#47

Posted 09 July 2012 - 04:43 PM

#48

Posted 09 July 2012 - 04:46 PM

-3 return front swirl does seem a bit small, but should be fine.

I'll answer your PM in a moment.

My problem with the AN3 return is that I cannot source an AN3/Quick Connect 3/8" Female fitting...... I was thinking of just asking them to build the tank with an AN6 return.....

#49

Posted 09 July 2012 - 04:48 PM

#50

Posted 09 July 2012 - 04:55 PM

I have ha fuel starvation and what you are experiencing isn't fuel starvation

I'd lean to agree here with Joe about Jimmy's car

JG, did you get a misfire at Abingdon?

I got fuel starvation at Pouhon at Spa which is the mother of all left handers and that was with approx 20 litres. (on 888s)

My experience was a loss in power similar to the rev limiter cutting in.

Later on with DW1 similar thing when he was down to about 10 litres or so at down the same run.

Could it be driving style and holding the car near the top end of it's RPM and something else causing the misfire?

#51

Posted 09 July 2012 - 05:05 PM

Edited by dw1, 09 July 2012 - 05:05 PM.

#52

Posted 09 July 2012 - 05:24 PM

Hmm, the pro alloy fuel tank, just when I thought I was define with modifications! I don't understand though how just having a larger tank prevents the starvation.

It's not the size... it's the baffles.

It stops the fuel sloshing to one side like the standard tank.

#53

Posted 09 July 2012 - 05:45 PM

Hmm, the pro alloy fuel tank, just when I thought I was define with modifications! I don't understand though how just having a larger tank prevents the starvation.

The Pro Alloy tank is baffled and has some clever check valves in place which keeps the fuel at the pump inlet supply

Guys I know this may not be the source of my issue but it's something I should have had fitted a LONG time ago anyway.

#54

Posted 09 July 2012 - 05:55 PM

#55

Posted 09 July 2012 - 06:05 PM

http://www.ebay.co.u...=item230ffc7d49

Means it's easier for me to replicate the Rally setup and just ask for the swirl pot with the An6 return instead of AN3

#56

Posted 09 July 2012 - 07:14 PM

#57

Posted 09 July 2012 - 07:32 PM

Hi Jimmy,

First off thanks for arranging the National, I had fun, learnt a bit and had some good passenger rides.

In regards to fitting a swirl pot here are a few points to consider if you go ahead:

1. Fitting the swirl pot on the parcel shelf just next to the lifter pump is the best place IMO (though your race regs may stipulate otherwise). This is because:2. Eliminate the hard plastic lines in the engine bay, replace with braided hose. This will:

- it will keep pipe runs to the shortest.

- locating behind the seats is the safest/strongest place in the car.

- cabin temps will be lower than engine bay temps and help keep your fuel cooler (which has mild safety and power benefit benefits)

- being in the centre of rotation of the car will exert the least g-forces on the swirl pot and fuel.

- If you get a slight leak of fuel in the cabin you will smell it immediately and take precautionary action. If it is in the boot engine bay, you wont know about it until you see flames bursting out of the rear.

- The cabin has no hot spots (like the exhaust or engine), so a minor leak will be far less likely to lead to vapour ignition.

3. If you decide to use a Bosch 044 pump, be aware that the inlet feed to this is AN8 (to provide extra inlet flow to the pump). Make sure your chosen swirl pot also has an AN8 outlet fitting or you will cause a restriction.

- 1) reduce the risk of a burst pipes if you sustain a major rear end impact.

- 2) the plastic pipes I/D is a restiction compared to AN6 or AN8.

4. Mount the pump on rubber if possible. It is very noisy.

5. Make sure you fit an additional fuel filter AFTER the power pump. This is important if you power pump fails, as its mechanism may disintigrate and go straight into your engine. Pump disintigration does happen.

6. As you run a race oriented car, you could consider the Bosch racing pump. This is in fact an ordinary 044 pump that is tested that it conforms to specification and then it gets a new part number, so hence gives you a bit more security for your £.

7. Try to ensure all pipework in the engine bay is flexible and can bend out of the way in case of severe impact.

8. Ensure the pump has thick 200+ watt capable power line as it can draw a lot of current (18 amps I think from memory). If you dont do this it will not flow to spec just when you need it most and may burn the line out.

9. You could get rid of the lifter pump in the tank carrier and let the 044 do all the work. Reducing 2 points of failure to 1 point is a good general strategy for a race car IMO, though this will lead to a different configuration. Also you have the advantage of using a 600+ BHP pump to supply for just 300 BHP, so it will not be strained in any way at all, hence less need for a lifter pump.

10. For extra safety you could fit and mount your swirl pot in its own fuel proof container/shroud. My setup has a fibre-glass box which will partially do this for example.

There are some pics and a short write up of my install here: https://sites.google.../07---update-24

Hope that helps.

Some good/bad in that and I've done LOADS of fuel setups over the years and made plenty of mistakes!!

Some notes ref above and other general notes:

- I wouldn't mount fuel kit in the cabin, fires DO happen and these day the methanol content in fuel eats through almost all the soft hoses available so the likelihood of a line failure on a modified fuel setup is high. Ambient temp where the swirl pot lives is a minor issue, the big heat comes from the pump and from turbos' etc near the fuel tank.

- The bosche 044 is a great pump but don't use it unless you need that level of delivery. If you could PWM the pump it would be fine but without that all you will achieve is cycling loads of fuel through past the reg and heating up the fuel which can have bad consequences.

- The hard plastic lines work well on the pressure side and are resistant to methanol which is good news. If you do use a big pressure pump then use the biggest delivery pipe to the pump that you can and give it a decent gravity feed. Rotary fuel pumps don't like to have to suck the fuel in and if they run dry they will fail very quickly.

- Because of above don't just use a Bosche 044 unless its picking up from a gravity fed collector in the main tank, if it has to draw the fuel up it won't last long.

- If I use soft line I stick to the black Aeroquip fuel line as it copes with meth better than anything else I've found. You can use braided but if you do then budget to replace every two years. I don't use braided because its impossible to inspect the condition of the hose and you only know when its failing when fuel pisses out.

- Nev is spot on ref the power supply, make sure its good.

- Don't use the sytec pump as a lift pump, its not designed for that purpose.

- If you fit a much bigger pump get the AFR checked on the dyno.

- As Nev says, filter after the pressure pump, sytec do a nice rebuildable one and the replacement cartridges are cheap.

- run out of brain power now...

#58

Posted 09 July 2012 - 08:24 PM

#59

Posted 09 July 2012 - 08:30 PM

#60

Posted 09 July 2012 - 08:30 PM

2 user(s) are reading this topic

0 members, 2 guests, 0 anonymous users