Where is the report button?

Press Alt + F4 for that one.

Edited by smiley, 06 April 2015 - 12:32 PM.

Posted 06 April 2015 - 12:32 PM

Where is the report button?

Press Alt + F4 for that one.

Edited by smiley, 06 April 2015 - 12:32 PM.

Posted 06 April 2015 - 05:47 PM

This is basically racism Where is the report button?

It's the red button with the cross in it; top right of your screen.

Lotus bouy!

Posted 06 April 2015 - 06:17 PM

Interested in how 8" works with obd-tuner and windows.

Was looking for an Android tablet to run Torque Pro in the VX(thanx for pointing out) instead of running classic gauges. Running obd at the same time would be great.

Posted 06 April 2015 - 09:19 PM

Posted 10 April 2015 - 03:46 PM

Posted 10 April 2015 - 09:03 PM

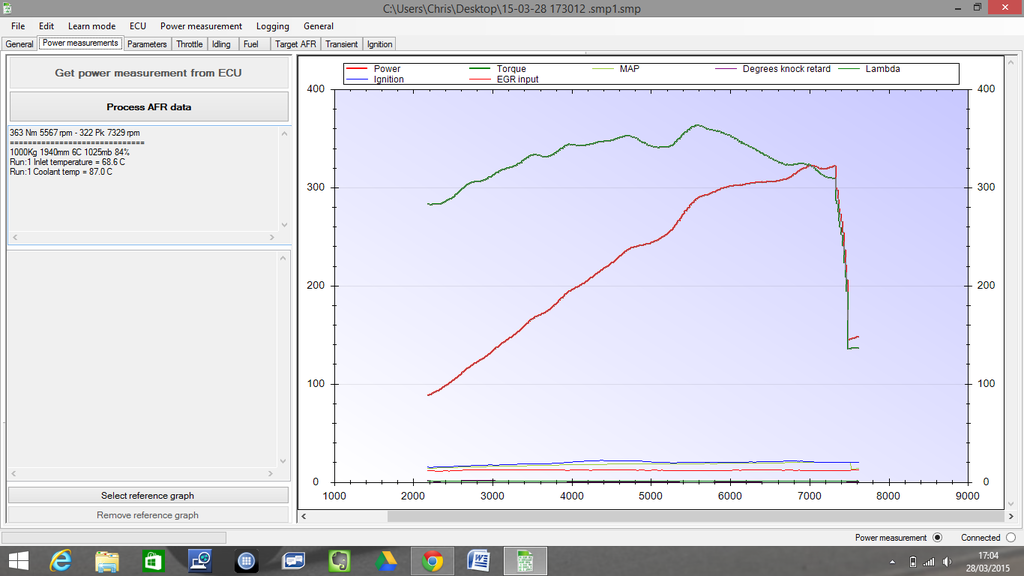

You need to separate the comparison into two section:

1. Under 5000 rpm

Here it looks like the graph of the harrop has a greater gradient, meaning the power increases at a greater rate with RPM. This will go back to the comment that it feels like it's pulling more at low RPM, torque measurements of Harrop cars vs. Eaton M62 would agree with that.

2. Above 5000 rpm.

Both graphs seem to have issues above 5000 rpm, most noticeably on the Harrop. I would say if these issues were eliminated you would be capable of much power (drawing a line following the gradient, you would get close to 400 bhp.

Now, it's a case of identifying the issue. This breaks down into two factors; fuel and air. Since you have started addressing the fuel one, let's focus on that. What duty cycle are the injectors at? Can you use that to calculate if your fuel pump is providing enough fuel - are the fuel pipe diameters wide enough for that rate of fuel flow?

Next step is airflow. Exhaust should be fine, assume biggest issue is inlet. I assume you're running a TMAP? In that case I would say the inlet manifold is not too restrictive (69 deg. C not bad), what about the air filter? Other cars have managed more than 300 bhp with the same manifold. What crankcase ventilation did you end up using? Could you be pumping a lot of crankcase gasses back into the inlet (effectively hot, dead air)

Edited by fezzasus, 10 April 2015 - 09:05 PM.

Posted 10 April 2015 - 09:18 PM

Posted 10 April 2015 - 09:22 PM

Is it a real Apexi? I know I bought a fake from ebay

also, dibs

Posted 10 April 2015 - 09:24 PM

Posted 11 April 2015 - 12:50 PM

Posted 11 April 2015 - 01:53 PM

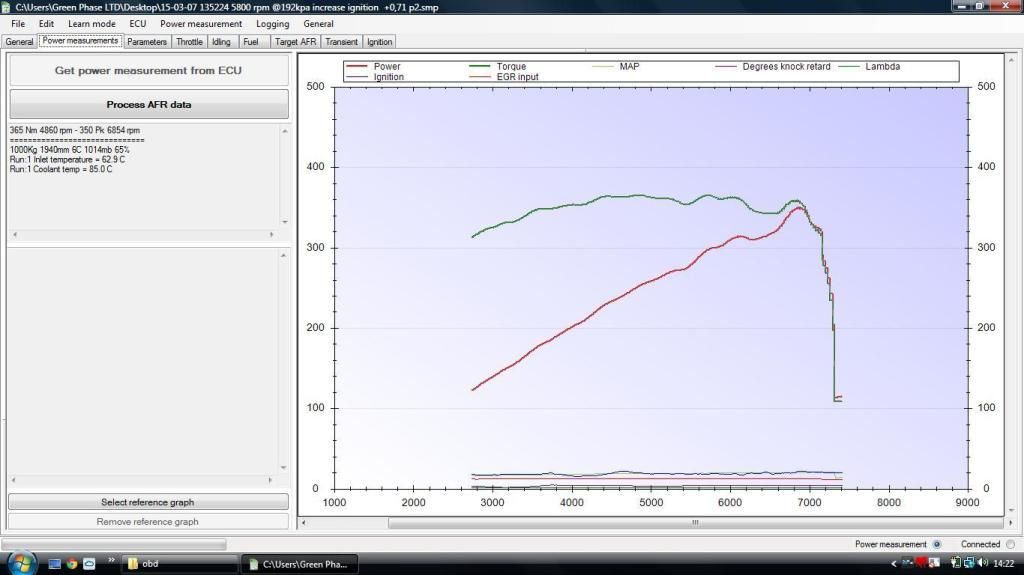

Here's a run from a harrop on a 2.0

It get's cut off to soon by the dyno guy, so at 7600 it should do around 320/330 (same as you)

He's also running a safe pully (80mm)

Just look at how smooth the powerline should go.

Something does not go a 100% in the high rpm on your's.

Edited by smiley, 11 April 2015 - 01:54 PM.

Posted 11 April 2015 - 01:56 PM

Just look at how smooth the powerline should go.

But remember the smoothness of the line will depend on how much data smoothing the dyno software applies.

Posted 11 April 2015 - 01:58 PM

Posted 11 April 2015 - 02:01 PM

Posted 11 April 2015 - 04:35 PM

You need to separate the comparison into two section:

1. Under 5000 rpm

Here it looks like the graph of the harrop has a greater gradient, meaning the power increases at a greater rate with RPM. This will go back to the comment that it feels like it's pulling more at low RPM, torque measurements of Harrop cars vs. Eaton M62 would agree with that.

2. Above 5000 rpm.

Both graphs seem to have issues above 5000 rpm, most noticeably on the Harrop. I would say if these issues were eliminated you would be capable of much power (drawing a line following the gradient, you would get close to 400 bhp.

Now, it's a case of identifying the issue. This breaks down into two factors; fuel and air. Since you have started addressing the fuel one, let's focus on that. What duty cycle are the injectors at? Can you use that to calculate if your fuel pump is providing enough fuel - are the fuel pipe diameters wide enough for that rate of fuel flow?

Next step is airflow. Exhaust should be fine, assume biggest issue is inlet. I assume you're running a TMAP? In that case I would say the inlet manifold is not too restrictive (69 deg. C not bad), what about the air filter? Other cars have managed more than 300 bhp with the same manifold. What crankcase ventilation did you end up using? Could you be pumping a lot of crankcase gasses back into the inlet (effectively hot, dead air)

This what i ended up doing with the pcv system,

dont think this is problem but i could just put it back to oem to prove this,

its how its been since putting the harrop on

Posted 11 April 2015 - 06:16 PM

No, I don't think that's the issue either. I think going for the low cost, easy wins like air filter and belt are a good starting point. to reiterate, I don't think you've met the limitation of the manifold, as others are getting higher power.

Posted 11 April 2015 - 07:00 PM

Edited by NickB777, 11 April 2015 - 07:00 PM.

Posted 11 April 2015 - 07:11 PM

Posted 11 April 2015 - 07:25 PM

Posted 11 April 2015 - 07:27 PM

Yes will do Not planning on having any restriction before chargerChill Make sure you use the correct 76mm pipe to connect the filter to the TB not the 70mm CS supply, every little helps.

0 members, 3 guests, 0 anonymous users