Elise Track Car Build Thread - Have You Lot See This One?

#121

Posted 25 December 2013 - 12:02 AM

#122

Posted 25 December 2013 - 12:28 AM

True, mechanical grip is very important.

Hence fitting 16x8 225 front and 17x9 255 rear and having the entire car setup with randy at donnington, so tyre pressures checked, pyrometer to make sure all of the contact patch is used. And im making the car as light as I can, I might see if I can get it weighed on boxing day to get an idea of where I am with it, i think its 700kg at the moment with another 15kg left to come off(carbon roof, proalloy tank, flywheel)

#123

Posted 25 December 2013 - 06:13 PM

I really hope this gets to a Time Attack round, so keep plugging away ![]()

#124

Posted 26 December 2013 - 12:44 PM

I really hope this gets to a Time Attack round, so keep plugging away

![]()

There's a lot of thought / work gone in and I'd love to see some good results ![]()

#125

Posted 26 December 2013 - 01:40 PM

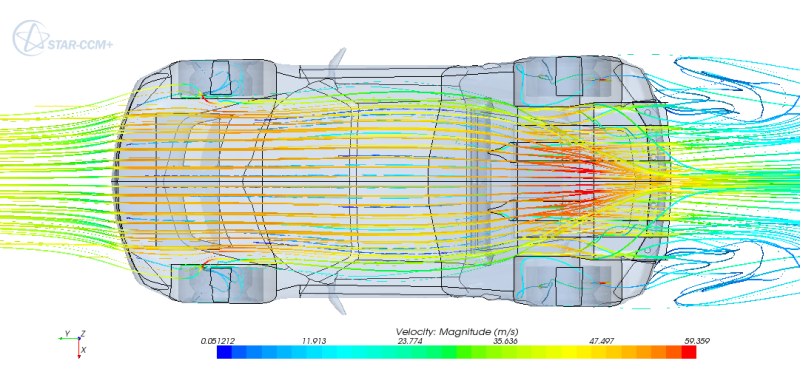

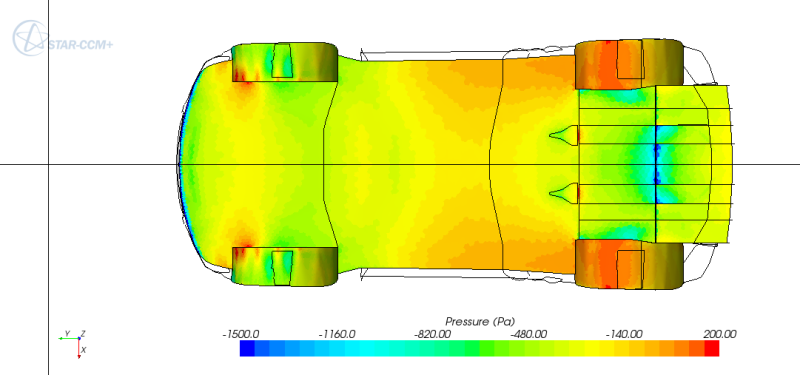

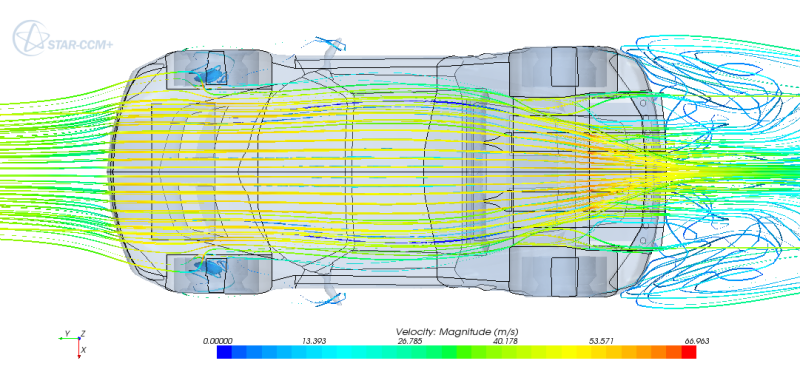

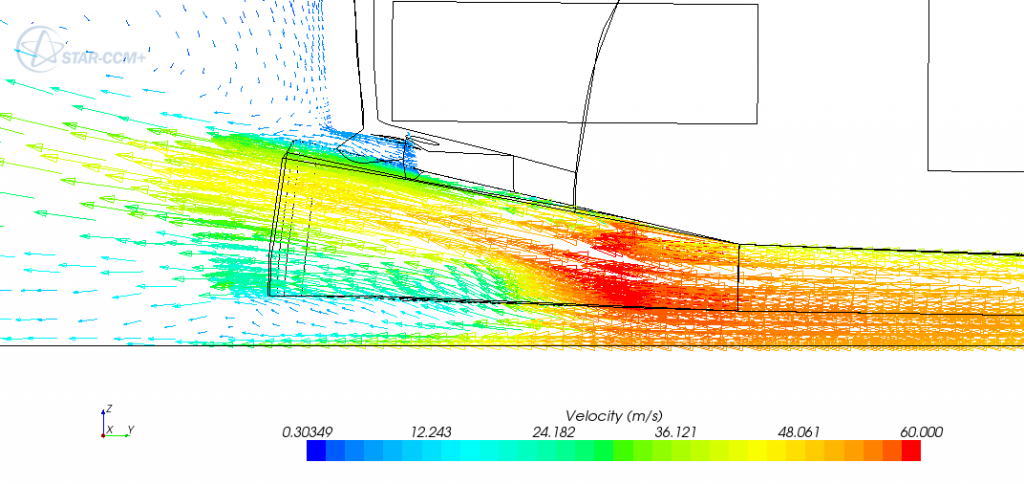

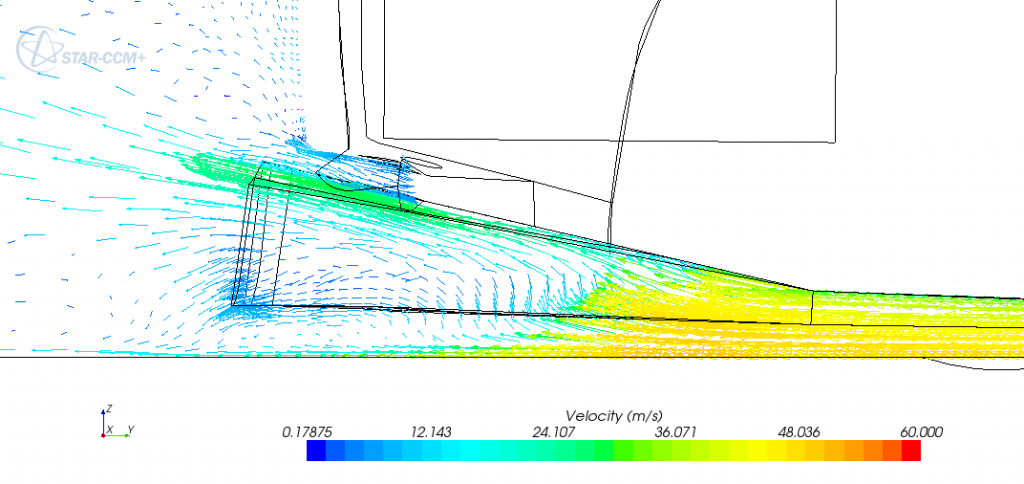

I have to agree the CFD modelling of the VX I've done showed that at the std ride height then the flow doesn't separate at 15 degrees, however if you drop the ride height down to 50mm then it does and you'd need to run a lower angle.Am I best just keeping it at the usual limit of 7* or will I gain an aerodynamic advantage by running it at a steeper angle, just film from behind to check tuffs are still pointing up to check attachment?[color=rgb(255,0,0);]My personal view is that a diffuser can be steeper than this on your type of car but it should only extend a short distance out at the rear. The reason for this is that you also get low pressure acting on the roof a diffuser that juts into the wake area, which will create some positive lift. Theres no arguing that bigger diffuser volume drives the underfloor harder to get more downforce there, but there must be a trade off and I dont advise going as far back as you have gone.[/color]

I also found the main things that improved the low pressure under the car was to fence off the leakage flow from the wheel arches and to extend the splitters down to the 40mm min ground clearance to stop the flow being sucked into the high depression in the center of the car.

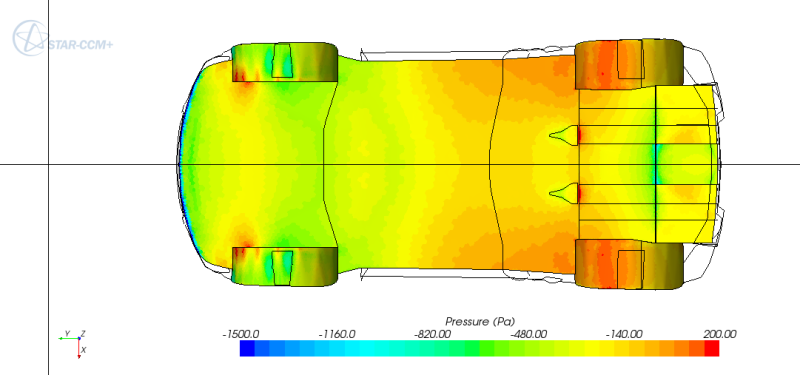

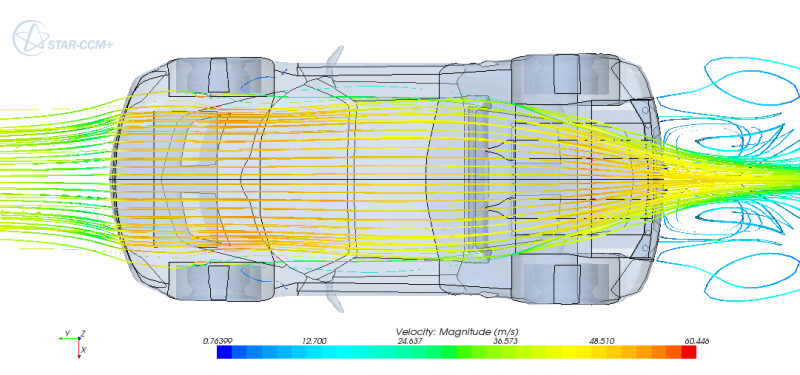

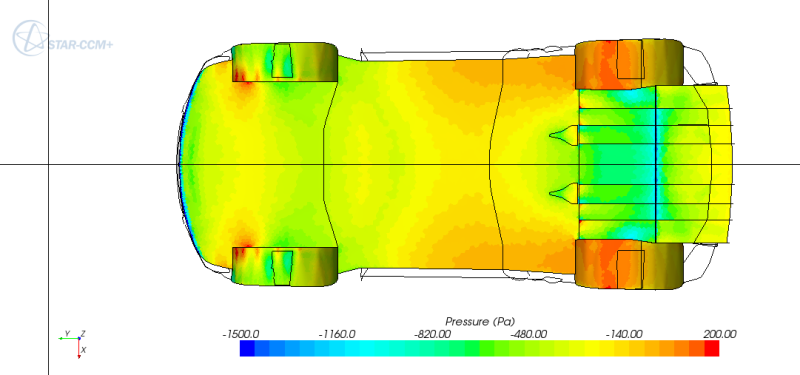

From the OEM and short style diffuser results below you can see that there is only a small are of low pressure, if you look a the stream lines it can be seen that this is because the high depression in the center of the car causes the most of the flow to be pulled down the center of the diffuser. Additionally you can see that the air flow under the body upto the rear wheel archesis pretty uniform but after that there is flow leakage from the rear wheel arches.

So to stop this you need to have multiple vanes in the diffuser that extend as far to the ground as possible, these are 40mm from ground, and extend the full length of the undertray

However you can get almost the same downforce by having just the outer vanes extending the full length of the undertrayt to stop the leakage from the wheel arches

You could probably fine tune the diffuser a bit more to get a few more % increase but cutting off the leakage from the wheel arches is what make the difference.

Edited by Winstar, 26 December 2013 - 01:47 PM.

#126

Posted 26 December 2013 - 01:54 PM

This arrangement may give you some problems, the reason that you don't see many braces on turbos is because the differential thermal expansion between the manifold and brace bar causes huge stresses in the manifold. Also the spherical bearing will mean that your brace won't do much to prevent vibrational stresses in the manifold.

#127

Posted 27 December 2013 - 01:23 AM

Thanks for all the info Winstar, very kind of you to share.

Strangely enough your information actually backs up alot of my thinking and what as also mentioned by Simon Mcbeath.

The time attack rules actually state that there can be nothing lower to the ground than 40mm when the vehicle is stationary, they go around with a little block thats 40mm and slide it under cars to check.

So what ive actually done is based my car on having a 90/120 ride height setup, with the diffuser strakes coming down to 40mm from the ground assuming its kept at 7*, if I run it higher than that then im sure you understand as it gets further away from the car the strakes leave a bigger gap with the floor.

My engine bay undertray also has skirts which connect up with the diffuser and run the full length to keep the high pressure wheel arch air out and also I have skirts that run the full length of the vehicle(these all connect together to leave no gaps) again keeping the 40mm clearance all the way along, so we should be able to keep that nice low pressure area underneath.

Obviously at speed the downforce will compress the car down by about 25mm in the high speed sections increasing the downforce more which as you mention effect the diffuser angle, so ill try it between 7 to 10 degrees and see how it reacts.

Also you mention about how the edges of the diffuser are less effective, if you look at my diffuser pictures you can see there are 2 thin sections and the middle ones are wider, since I know I wont be able to completely stop the high pressure air getting into the diffuser stream ive put sacrificial sections each end, im hoping that they will retain any high pressure air in those sections and let the inner part of the diffuser do its job more effectively.

The manifold brace in the end was scrapped because the concern was if that brace got very hot and made the metal expand it would be applying a vertical force on the head which is not ideal, im not saying it will cause head gasket failure but its something I dont want to have any potential thoughts about, we are now going to make a brace from the inlet manifold over the engine to the turbo to stop and horizontal flex.

#128

Posted 28 December 2013 - 09:57 AM

#129

Posted 28 December 2013 - 11:01 AM

#130

Posted 28 December 2013 - 11:01 AM

thats exactly what we are doing but im not going to bolt it to the head, im going to bolt it to the inlet manifold as ive already lost one rocker cover bolt from vibration when it was supercharged. Im just waiting for a couple of aluminum nuts to be welded into it so I can attach the brace

#131

Posted 29 December 2013 - 12:22 AM

Well plumbed in the boost pipes and to have a look at expected spool times.

In 3rd gear we are seeing 8psi at 3800rpm with a big boost leak and only 70% throttle(need to make a new throttle cable bracket as it doesnt allow full throttle operation) so hopefully with the amendments tomorrow we should get that down to 3500rpm, cant go any further until we put the bigger injectors in.

We will tune it at 15psi and see where we are power wise

#132

Posted 02 January 2014 - 01:30 PM

Little update.

My sump baffle arrived in the post, looks fairly easy to fit, hopefully it should help keep the oil pickup ok under lateral G, havent really got the money for a dry sump and Ive heard a few issues with the accusump setup

Does anyone have experience with these in a race situation or on slicks?

Next I decided to go an weigh it, to see where we are as ive taken alot off but put alot on so.....so with no fuel it weigns 710kg which when you think im running a turbocharged/chargecooled engine, alot of aero and much bigger wheels isnt that bad I suppose, I would have liked it to be under 700kg, but ive still got an EP flywheel and a ali fuel tank so that should get me down to 700kg flat, Ive aimed for 680kg so need to have a good think about where else I can remove 20kg, the next thing will be carbon roof then maybe see what weight I can save on the brakes.

Also fitted a turbo jacket that came today to try and reduce some engine temps, only this is, I forgot about the internal wastegate until I came to fit it, so I had to make a little hole for it to pop through, dont know if this will effect anything as heat might be able to get inside the jacket through the hole, soon find out.

Also took the car for a run, used to get a very hot fuel tank from the exhaust manifold heat when it was supercharged to the point where I could actually cook food when driving, I was hoping that running the turbo up top would stop that happening and im happy to say it has, i put my hand on it and its cool to the touch ![]()

Just need to wrap the manifold and put some heat shielding on the bulkhead next time I pull it all off.

Edited by turbotoaster, 02 January 2014 - 01:31 PM.

#133

Posted 02 January 2014 - 02:23 PM

Good progress.

#134

Posted 02 January 2014 - 02:49 PM

#135

Posted 02 January 2014 - 03:26 PM

710 Kg is to die for (especially with a heavy turbo), makes my tubby seems like a fat-arse at 940 KG. Keep spannering and thanks for updating us

It is very heavy, I think my turbo and manifold is about 20kg so its a big old lump, the manifold pipe thickness is 3mm! I could have made it thinner, but I wanted it to be a fit and forget item.

I think that if I were to put it back to N/A and no aero it would be about 660kg which would be fairly light, but slower around the track.

the 6-700kg was the reason I went with an s1 elise in the end, I looked long and hard at getting a vx220 turbo as they are very good value for money, I did see a blue one with about 300bhp which I really liked but this one came up with all the bits I wanted hence buying it.

I really love your build Nev, seems you get a big of grief for your car but you are pushing the boundaries forward and I respect that, if everyone did the same we would still be driving completely stock cars.

only thing about this turbo conversion will be boost threshold, the car starts waking up at 4000rpm, but I know ill only be able to rev it to 7000rpm as I have shorter rods so the powerband might be very small, I cant tell yet till I install my vxr injectors as the stock injectors max out at 4200rpm.

Ive got a couple of options then, either put in a set of correct length QED rods to allow me to run to 8000rpm giving me a bigger powerband while having the head worked over to increase flow to help with spool or buy a gt2871 with a t3 rear housing 5 bolt, both arnt cheap options so maybe ill look at that after the season is over, a few people did mention to me that it would be to big but I wanted to see for myself and since the turbo is only £150 I can afford to run it for a while anyway, ive got antilag in the emerald so might see if that will help, its not like lost aload of money as I could probably sell it working for £50-80

I used to drive a renault 5 turbo that made 2bar of boost at 5500rpm and had to change gear at 6500rpm, it was hard work I adapted to it and it was fairly fast, I hope this isnt like that as it will make it more tricky on track

#136

Posted 03 January 2014 - 12:40 PM

regarding the turbo brace cosworths use a nice setup look at there for support

i run a 2871r with the larger housing and that see's full boost around 4,400rpm but i rev to 8.2k on my 1600

#137

Posted 06 January 2014 - 11:03 AM

regarding the turbo brace cosworths use a nice setup look at there for support

i run a 2871r with the larger housing and that see's full boost around 4,400rpm but i rev to 8.2k on my 1600

What engine is that based on, a rover k series or something else?

I looked at the cosworth braces, mine will be identical to them but instead of bolting to the rocker cover, mine will go over the inlet manifold as I dont want to risk stripping the bolts out of my rocker cover as ive lost one already this way.

I think ive found another turbo that I might get in the future, its a t34 sized turbo with all the correct rear housing ill need at a good price, but for the moment im having the suspension refurbed, atb diff and flywheel put in so that can be something to look at once I have run the engine up to 7000rpm so see what is actually happening.

#138

Posted 06 January 2014 - 01:08 PM

I take it that when you run it up, you do so under load?

#139

Posted 06 January 2014 - 01:15 PM

regarding the turbo brace cosworths use a nice setup look at there for support

i run a 2871r with the larger housing and that see's full boost around 4,400rpm but i rev to 8.2k on my 1600

What engine is that based on, a rover k series or something else?

I looked at the cosworth braces, mine will be identical to them but instead of bolting to the rocker cover, mine will go over the inlet manifold as I dont want to risk stripping the bolts out of my rocker cover as ive lost one already this way.

I think ive found another turbo that I might get in the future, its a t34 sized turbo with all the correct rear housing ill need at a good price, but for the moment im having the suspension refurbed, atb diff and flywheel put in so that can be something to look at once I have run the engine up to 7000rpm so see what is actually happening.

ford 1600 sigma engine

#140

Posted 06 January 2014 - 03:40 PM

I take it that when you run it up, you do so under load?

Yes, full throttle now in 4th gear with the datalogger running, turns out my map sensor was playing up and we were making less boost than i thought, its more 4000rpm 7psi so very similar to my old rotrex, so im guessing the power under 4krpm will be lower than the rotrex and above that it will be more as I didnt use to make 10psi till 5500rpm and then used to drop boost above that on the rotrex(210bhp/190ftlbs)

Looking more closely at the comp/turbine wheel they seemed to be GT3076 sized which would explain the big threshold, my fault for not really thinking about this more before I bought it but I was only going to use it as a setup turbo so I could get the engine running and had no intention of keeping it long term, but also I just assumed that it would be laggy and running lower boost it would be like my rotrex, so i think dropping down a size of turbo will most likely be the best solution, maybe save it for road use so I dont wear out the other turbo and silverstone for the run down the back straight haha, as I can have loads of maps saved on my laptop and only takes a few seconds to upload a new one

regarding the turbo brace cosworths use a nice setup look at there for support

i run a 2871r with the larger housing and that see's full boost around 4,400rpm but i rev to 8.2k on my 1600

What engine is that based on, a rover k series or something else?

I looked at the cosworth braces, mine will be identical to them but instead of bolting to the rocker cover, mine will go over the inlet manifold as I dont want to risk stripping the bolts out of my rocker cover as ive lost one already this way.

I think ive found another turbo that I might get in the future, its a t34 sized turbo with all the correct rear housing ill need at a good price, but for the moment im having the suspension refurbed, atb diff and flywheel put in so that can be something to look at once I have run the engine up to 7000rpm so see what is actually happening.

ford 1600 sigma engine

Ok well, I would imagine they will be flowing similar levels of air then, what boost do you run on that engine?

Edited by turbotoaster, 06 January 2014 - 03:42 PM.

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users