Z22Se Engine Liners

#1

Posted 09 April 2014 - 04:49 PM

#2

Posted 09 April 2014 - 05:16 PM

This link had some info but is broken for me. Wanna check it?

http://turbovmax.com...om:80/PDF/Birth of the Ultimate Import Fighter.pdf

#3

Posted 09 April 2014 - 06:13 PM

#4

Posted 09 April 2014 - 06:15 PM

Dilbert manifold with a rotrex system ![]()

#5

Posted 09 April 2014 - 06:26 PM

#6

Posted 09 April 2014 - 06:49 PM

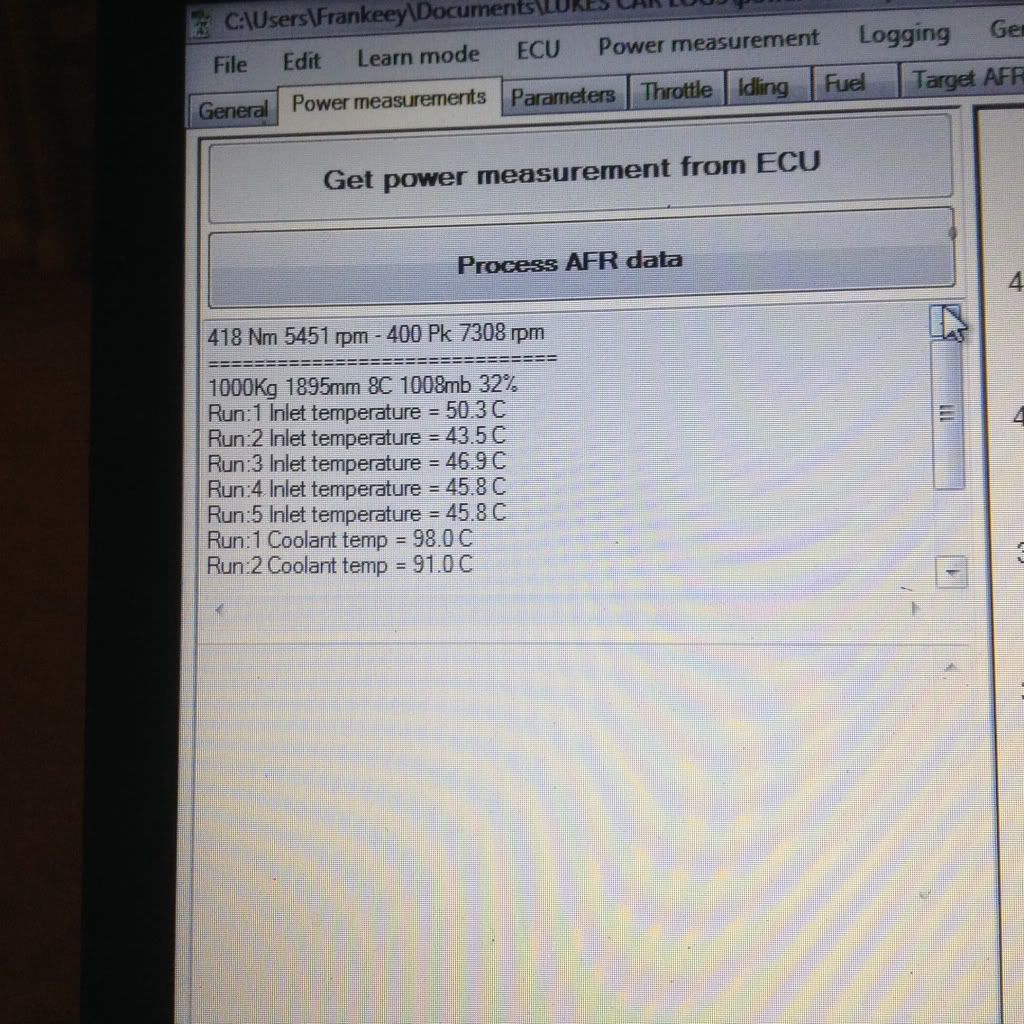

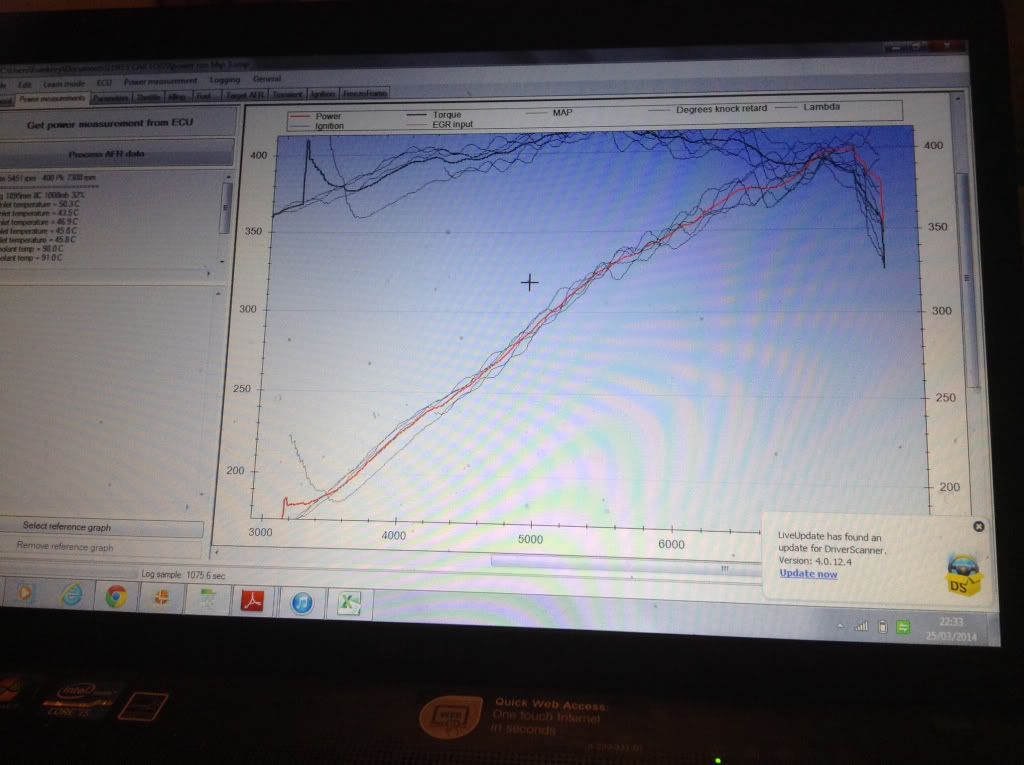

Mines pulling 400 easy on the Dutch software with good inlet temps. So if I add the 30bhp for the supercharger then my engine is doing 430bhp.Getting over 400 will be the problem because off the intake manifold

#7

Posted 09 April 2014 - 06:53 PM

#8

Posted 09 April 2014 - 06:54 PM

#9

Posted 09 April 2014 - 06:55 PM

#10

Posted 09 April 2014 - 06:57 PM

Edited by haggi961, 09 April 2014 - 07:05 PM.

#11

Posted 09 April 2014 - 07:06 PM

#12

Posted 09 April 2014 - 07:08 PM

#13

Posted 09 April 2014 - 07:09 PM

#14

Posted 09 April 2014 - 07:11 PM

What would you say the higher and lower levels are?The mild issue with the power to break things at the higher levels is that they just dropped nitrous in till stuff broke... No hint on how sustained the power was or how gently they added it. The lower levels are acceptable but at higher numbers its a bit of a grey area

#15

Posted 09 April 2014 - 07:28 PM

From what I've read (and it is just from that link and cobalt net etc) the liners aren't that bad. The build book says 400 bhp but further investigation suggests that its something about the block head interface that becomes a bit dodgy. It was something to do with cylinder pressures raising the head and the cylinders move / break. Hence why the gen 3 block has top bracing and is good for much higher power with similar liners. People have found that thicker head studs and fire rings help keep everything clamped down and aligned. That original link suggested that arp studs and the copper gasket with fire rings is good to 600 bhp.

If you do liner a block then there have been problems with the darton blocks breaking in half. The machining can weaken the block leading to the break. The dartons also suffer vertical slip causing catastrophic damage too. There's a 'bates' liner which is a 3mm thick nodular iron liner but I'd guess this will suffer from the head lifting issues. I've found a place that will do a similar liner to the bates one but haven't done anything about it yet.

Obviously this all comes from reading other peoples failures and reasoning over how to solve it etc. My thought is that finding a gen3 block would be the best way.

#16

Posted 09 April 2014 - 07:43 PM

Not bad inlet temps, is that the first run?

#17

Posted 09 April 2014 - 07:44 PM

If I was chasing power I wouldn't be selling my GarrettIt's not linear... Because it costs 30bhp to make 250bhp at the fly doesn't mean it only costs 30bhp to make 400 at the fly. Aimy, power isn't everything, you might understand one day

#18

Posted 09 April 2014 - 07:55 PM

Thanks for that and some intresting points. I have apr head bolts fitted so that's ok. I also have the Saab gasket fitted but not sure if it's copper so need to find out. What's these fire rings you talk about?From what I've read (and it is just from that link and cobalt net etc) the liners aren't that bad. The build book says 400 bhp but further investigation suggests that its something about the block head interface that becomes a bit dodgy. It was something to do with cylinder pressures raising the head and the cylinders move / break. Hence why the gen 3 block has top bracing and is good for much higher power with similar liners. People have found that thicker head studs and fire rings help keep everything clamped down and aligned. That original link suggested that arp studs and the copper gasket with fire rings is good to 600 bhp. If you do liner a block then there have been problems with the darton blocks breaking in half. The machining can weaken the block leading to the break. The dartons also suffer vertical slip causing catastrophic damage too. There's a 'bates' liner which is a 3mm thick nodular iron liner but I'd guess this will suffer from the head lifting issues. I've found a place that will do a similar liner to the bates one but haven't done anything about it yet. Obviously this all comes from reading other peoples failures and reasoning over how to solve it etc. My thought is that finding a gen3 block would be the best way.

#19

Posted 09 April 2014 - 08:13 PM

No had a good few runs before it. You can see my inlet temp got up higher on the first power run due to my sitting in a lay by for about 15 minutes with my car running looking over my data. I need to pick your brains soon if that's ok with the pcv?Not bad inlet temps, is that the first run?

#20

Posted 09 April 2014 - 08:23 PM

fire rings are a stainless ring that sits in a groove machined around the top of each liner. Its supposed to dig into the gasket to provide a proper tight seal and help keep the cylinder aligned. I cant remember the exact amounts but the liners are left a few thou proud of the block and the rings are few thou proud of that. Copper gaskets are GM racing ones from the US and are reusable.

ETA:

Edited by FLD, 09 April 2014 - 08:25 PM.

2 user(s) are reading this topic

0 members, 2 guests, 0 anonymous users