If someone is willing to play about with hinge and bulkhead it will fit a standard engine bay :-)That frankenstein only fit's in Lee's car

Supercharged Intake Temps

#341

Posted 27 June 2014 - 02:57 PM

#342

Posted 27 June 2014 - 03:35 PM

where does the heat go?

Read up on entropy and the heath death of the universe ![]()

Or are you referring to water injection? When it's still water, heat capacity is 4 times that of air, so it takes away at least some heat. When it turn into gas, you got the phase transition energy. And it acts like a natural octane booster, slowing the burn. Not saying it's a solution, just curious why it's not

#343

Posted 27 June 2014 - 03:52 PM

Think I posted this before, but i.m.o. this is how a watercooled SC system should look like. Compact, short air routing for decent throttle response and with some runner length to shoot into our ports:

Now where is that sawzall to cut-off my oil filer.... ![]()

But I think there would be more people willing to pay for a better manifold that may only require for relocation of some bolted parts. (like starter motor and alternator.) Not major modifications to the block that require a complete removal & dismantling of the engine... ![]()

Edited by Exmantaa, 27 June 2014 - 03:54 PM.

#344

Posted 27 June 2014 - 04:13 PM

#345

Posted 27 June 2014 - 05:12 PM

where does the heat go?

Read up on entropy and the heath death of the universe

Or are you referring to water injection? When it's still water, heat capacity is 4 times that of air, so it takes away at least some heat. When it turn into gas, you got the phase transition energy. And it acts like a natural octane booster, slowing the burn. Not saying it's a solution, just curious why it's not

It's def an option, but it's another tank to fit somewhere, you need to fill regularly on track then there's pump and some way of activating it only when it's needed, etc, etc... although by all the other talk it's got to be less effort and more chance of happening than aircon or a redesigned manifold

If someone is willing to play about with hinge and bulkhead it will fit a standard engine bay :-)That frankenstein only fit's in Lee's car

This

So if Lee's plate/sandwichy thing can bring track day temps down enough it's much easier to modify the engine cover or have someone make a larger one (racing engine cover?)

It's not a perfect but the ideal solution seems well out of reach

#346

Posted 27 June 2014 - 05:12 PM

Lee/Scuffers, did you get any logging on track from the national?

#347

Posted 27 June 2014 - 06:59 PM

No but car all good now so will do soon ;-)Lee/Scuffers, did you get any logging on track from the national?

#348

Posted 28 June 2014 - 01:04 PM

unfortunately the one resource i don't have much of is time and given the response i got last time i asked then i didn't think it was worth the investment. the oem laminovas perform very well on the lsj engine i had the data from the dyno testing when i was deigning/analysing the NEF V6 cc system. However not only are you putting much more mass flow through to get the power but by fitting it to a 2.2 you're increasing the gas velocity and simplistically pressure loss = 0.5*K*density*velocity^2 where K is a constant for the flow pathif you have the resources, go for it... more than happy to help out with this... the Lotus one posted up is OK, but has issues, you have to remember that the more air volume between the throttle and the engine the more problematic in terms of throttle response, as well as idle/low flow rate instability. Also, air to air just does not work in a mid engined setup without some major compromises. somebody mentioned the restrictive nature of the laminovas, and yes, at higher (air) flows that's a significant problem, with the original M62 install probably not so bad, but with 300+hp airflows they will be significant (more restriction = more parasitics and more heat). ultimately, water is the way forward, using as high a density core as possible without causing significant air restriction, hence why I had the sandwich coolers made for the Honda's (that Lee is now using). the real issue here is as usual, you get space limited. re: exhausts, yes, the more restrictive, the more MAP pressure you will get, more MAP = more heat & parasitics.

#349

Posted 28 June 2014 - 01:41 PM

#350

Posted 28 June 2014 - 01:49 PM

Just out of interest, how would a small / med size turbo unit compare to the M62 with regards to IATs - I presume running higher pressure (~20psi) lower flow would result in higher IATs? Would the laminovas become more of a restriction with increased pressure but low mass flow?

not sure what you're trying to get at?

turbo will be more efficient at 20Psi by some way (much over 10Psi for a 62 is into a world of heat)

laminova wise, it's flow that's the issue, higher flow = more resistance

#351

Posted 28 June 2014 - 03:19 PM

#352

Posted 28 June 2014 - 04:16 PM

#353

Posted 28 June 2014 - 05:04 PM

Anyone know what boost levels we see with the various pulleys 3.5(?),3.35, 3.1, 2.9?

I assume that the standard pulley (3.35") would see the boost sitting in the efficient range for the m62?

#354

Posted 28 June 2014 - 06:22 PM

I have a 2.9" Modular on mine at 242 lbs torque, 300bhp its running at the max ,I think its about 1 bar of boostAnyone know what boost levels we see with the various pulleys 3.5(?),3.35, 3.1, 2.9? I assume that the standard pulley (3.35") would see the boost sitting in the efficient range for the m62?

#355

Posted 29 June 2014 - 08:28 AM

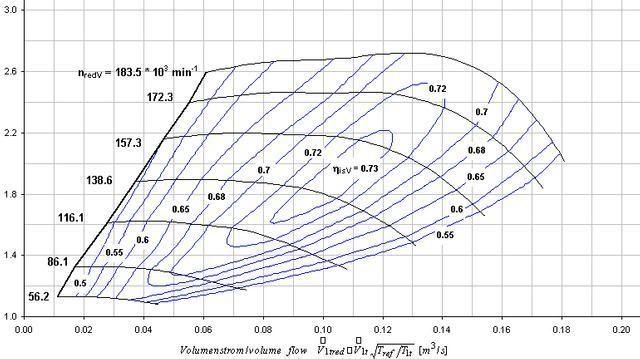

probably worth posting this up so people can see what we are on about.

this is the performance chart for the MP62, note this is 'at best' as in what Eaton use to sell it and is based on optimum conditions etc. (as in of you run one on a track car for 30 mins and get it properly heat soaked, it's performance will be nothing like this!)

as a comparison, this is the equivalent chart for a GT2860RS (capable of ~320hp in a similar install)

#356

Posted 29 June 2014 - 09:02 AM

Handyprobably worth posting this up so people can see what we are on about.

this is the performance chart for the MP62, note this is 'at best' as in what Eaton use to sell it and is based on optimum conditions etc. (as in of you run one on a track car for 30 mins and get it properly heat soaked, it's performance will be nothing like this!)

as a comparison, this is the equivalent chart for a GT2860RS (capable of ~320hp in a similar install)

http://www.turbobyga...ges/turbogroup/

performance_maps/739548-1comp.jpg

#357

Posted 29 June 2014 - 09:06 AM

These might need some explanation!

the flow for an Eaton (as in a positive displacement pump) is in M3/Hour - at 25C ambient (as in the temp of air into the SC), 1M3/hour = 0.043432 lb/min so 500M3/hour = 21.7 lb/min.

PR is pressure ratio, this is the difference in the pressure of the inlet over the pressure of the outlet, this may look like boost pressure, but be careful, it's not, a PR of 2 means the outlet is double the inlet pressure so you would think this means 1 bar boost - BUT!

the pressure of the inlet will not always be the same at atmospheric, at higher airflows, it has to overcome the airfilter, pipework etc to the SC inlet, typically, it will be anything from ~95-98% ambient, than at the outlet, by the time you have got to the engine though the pipework, intercooler, throttle, etc, you will lose some pressure, so 1 bar boost at the engine is actually now significantly over a PR of 2.

#358

Posted 29 June 2014 - 11:36 AM

This should fir nicely in here; the TVS 1320 map:

Already better at higher pressure ratios, but this shows why with an SC it is key to try to keep the boost pressure as low as possible with a good flowing head, decent cams and a proper exhaust. Simply slapping a smaller pulley on it is not the way to go... ![]()

#359

Posted 29 June 2014 - 12:15 PM

So here's the compressor chart for the high response twin-scroll turbo unit I was thinking of.. It appears that, much like the M62, it is getting well out of its efficiency range (and increasingly pumping hotter air) at the ~300bhp target. In practice they produce more bhp than that, but when you factor in the power consumption of the M62 operating at a similar power level (~10%?) I guess both are similarly inefficient.. Its no surprise I guess as this unit is designed for OEM street cars a producing maximum torque (~260lb/ft) @ ~2,000rpm..

Albeit this is in a standard configuration (I assume) and not optimised with any improvements in exhaust size / configuration, that may or may not help..

#360

Posted 29 June 2014 - 03:36 PM

So here's the compressor chart for the high response twin-scroll turbo unit I was thinking of.. It appears that, much like the M62, it is getting well out of its efficiency range (and increasingly pumping hotter air) at the ~300bhp target. In practice they produce more bhp than that, but when you factor in the power consumption of the M62 operating at a similar power level (~10%?) I guess both are similarly inefficient.. Its no surprise I guess as this unit is designed for OEM street cars a producing maximum torque (~260lb/ft) @ ~2,000rpm..

Albeit this is in a standard configuration (I assume) and not optimised with any improvements in exhaust size / configuration, that may or may not help..

compressor maps are just the compressor itself, not attached to anything...

remember, with a turbo, this is only half the story, you have the turbine wheel/housing optimise too (both with their own performance maps)..

when the turbo map shows 70% efficient, it's worth remembering that thats just the adiabatic efficiency of the compressor section, it does not mean the turbo is 70% efficient (and it will be far from that)

adiabatic efficiency is a measure of how much heat gain the air will get over and above the gain due to the combined gas laws (ie, if you compress a litre of air into half a litre, it's temp and pressure will increase, before you consider the heat caused by the mechanics of compressing it).

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users