Daryl's Plastic Box Of Joy

#81

Posted 15 January 2016 - 04:36 PM

#82

Posted 02 February 2016 - 06:11 PM

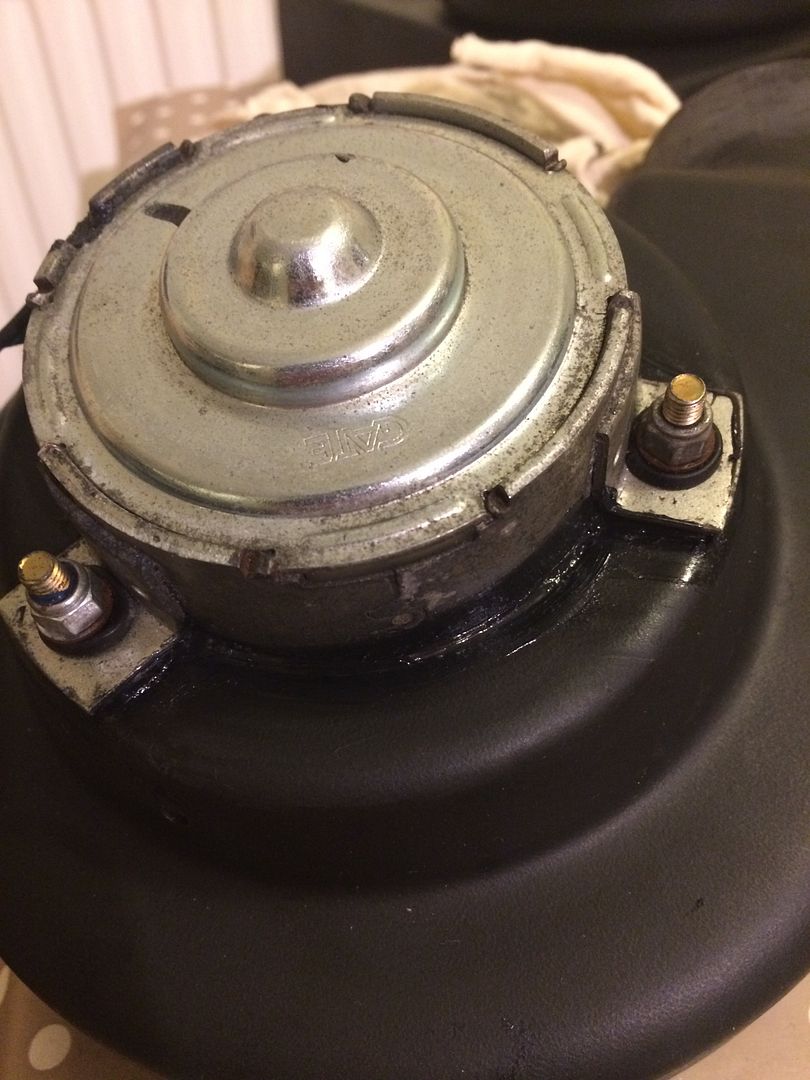

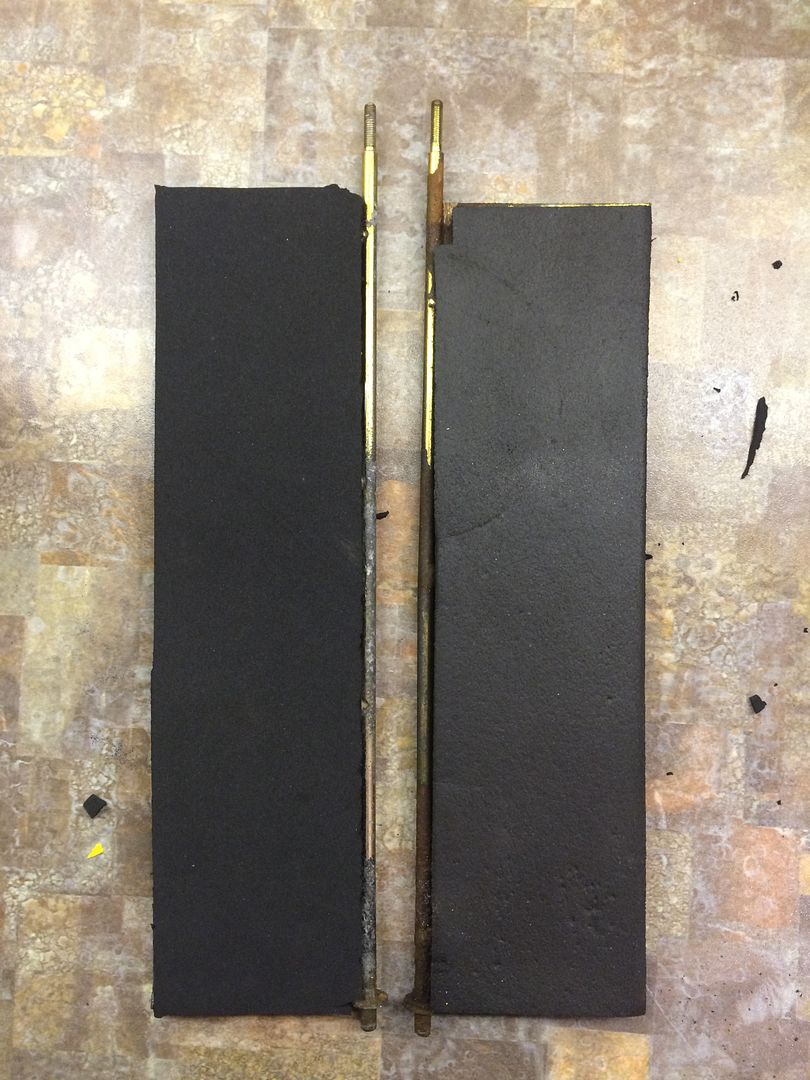

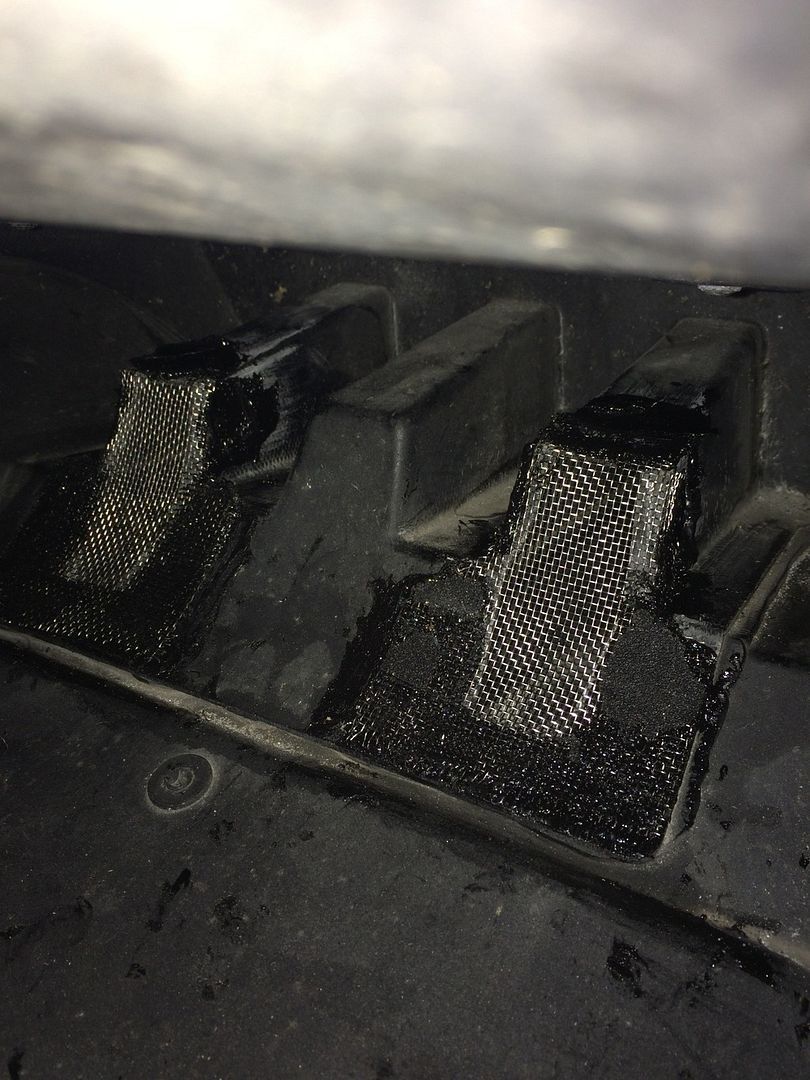

Also got my act together and got the heater box reassembled. Extended the foam a little on the flap, so it sealed all the way around. Still has free movement, but fits alot better now. Went around every gap with silicone as well as sealing all the rivet holes etc. Hopefully it will work a treat.

Original flap on the right, refoamed one on the left.

Doing the same thing with the junction box under the screen also, so that has a similar issue with lots of gaps, though as it does not get so hot there, the distortion is not as bad.

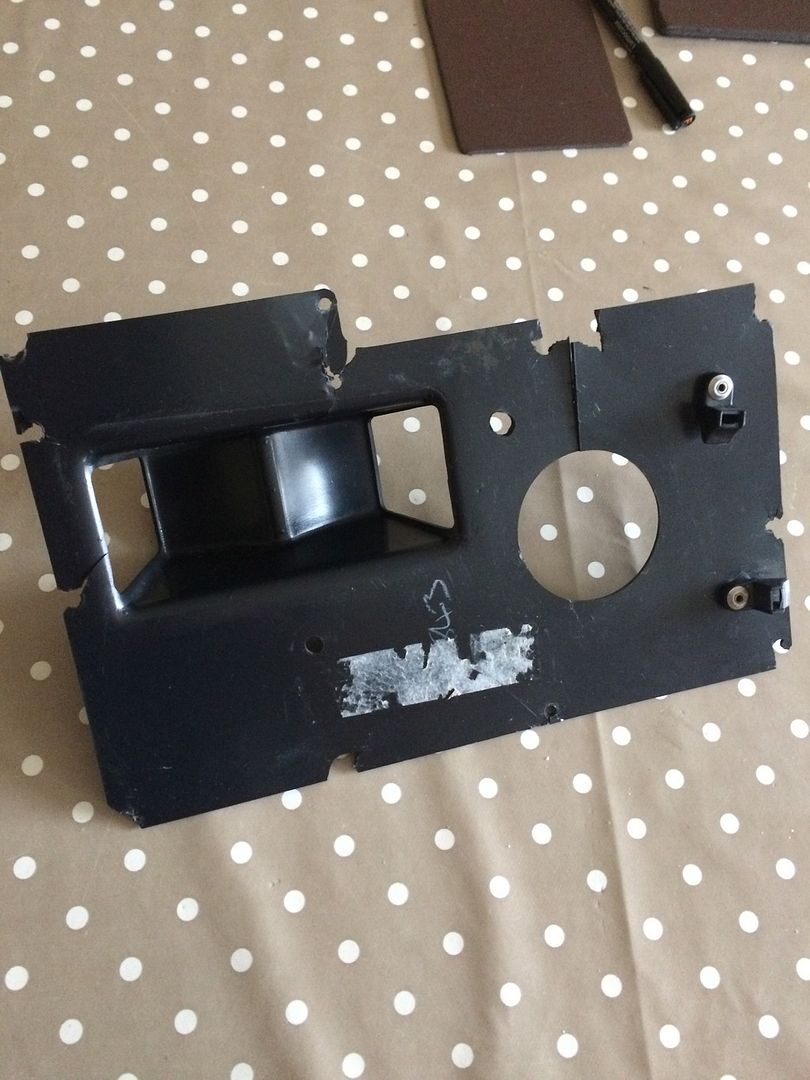

While the dash was out, i thought id have a go at retrimming it myself, as its the less expensive way to start with. The covering that was on it bubbled loads in the heat, and it annoyed me, so ripped it off. The chassis mounting bracket came away in 2 bits as well, so i need to try to source another one from somewhere.

Covering was only stuck arounf the edges, and in the groove, which explains the bubbling. Thinking il get a new covering now i have a template, and glue it down properly.

#83

Posted 03 February 2016 - 02:49 PM

Just got to do the edges now, but thought id wait to see how the starter button area and groove settle first. Spot the novel device used to keep the material in the starter recess....

#84

Posted 03 February 2016 - 03:50 PM

Getting there matey!! Let me know if need some help in the next few weeks..

#85

Posted 03 February 2016 - 03:53 PM

#86

Posted 03 February 2016 - 04:06 PM

Cheers Matt. Hopefully will start to get things put back together. Just debating if i should remove the rear subframe, and clean up the usual suspect areas, seeing as it can be done fairly quickly. Will save me doing it at the end of the year. Will get the other bits sorted, and see where i am time wise

Probably worth doing tbh as it's in bits already!

#87

Posted 03 February 2016 - 04:09 PM

Get yourself a can of [color=rgb(40,40,40);font-family:helvetica, arial, sans-serif;]Duralac too![/color]

#88

Posted 03 February 2016 - 04:26 PM

#89

Posted 10 February 2016 - 12:47 AM

Well, today i used a rotary file, (great tool) and ground away wnough material on the airbox bracket to get a socket in to remove the rear subframe bolt. Next job will be sorting out about removing the rear subframe, and getting everything cleaned up and sorted. Wont paint the subframe, but will be happy to see it pressure washed, and degreased after a CV boot failure sprayed grease eveywhere. Also interested in seeing how much corrosion I have between the chassis and the subframe. Dambers and springs have been parted, which a messy job, loads of dust, and debris. Springs are pretty corroded, so will probably get them powder coated again, to make them look decent. Also found that the ride height L-R was totally different, not sure if this normal or not. Dont know which side was higher, as I didnt label the dampers. Tried various methods of getting the circlip that holds the bearings in the dampers out, but alll failed, so leaving them in now, and just going to grease them up. Probably sending the dampers for a refurb next year.

Fitted new header tank, which makes me realise how bad the original was. Going to start getting my back side in gear now, and get the car back together. Hoping to get booked in with MBR at the end of March ish.

#91

Posted 10 February 2016 - 04:17 PM

#92

Posted 07 March 2016 - 07:37 PM

#93

Posted 11 March 2016 - 05:01 PM

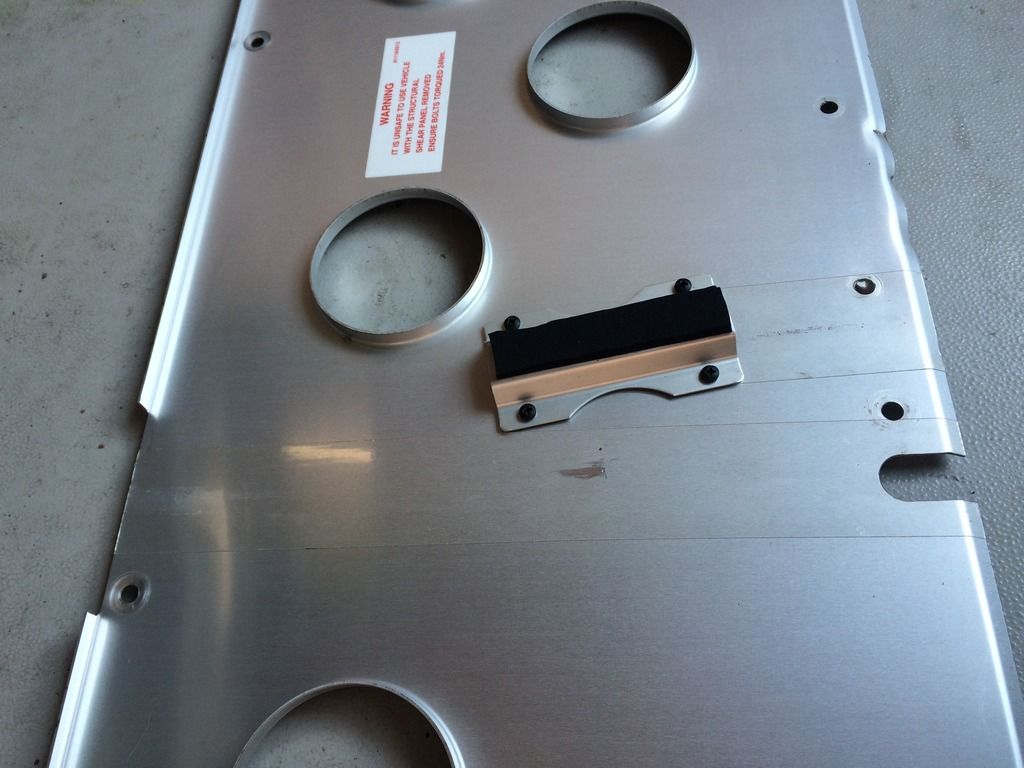

An old one that i managed to secure through Liz.

New one with it

#94

Posted 11 March 2016 - 05:46 PM

#95

Posted 14 March 2016 - 11:51 AM

Nice one mate!

#96

Posted 14 March 2016 - 07:36 PM

Also found out my Piper Exhaust has bowed on the flange, apparently not uncommon. Due to time and money, iv re-fitted it. It has all pulled up nicely, but when funds allow, il be getting a Tullet i think.

#97

Posted 17 March 2016 - 11:18 PM

The mesh is not my neatest work ever, but its a pain because of the shape. Ended up bonding it in 3 stages. One for the bottom bit, one for the side faces, and one for the top face. All with various clamps, wedges and spanners wedged in to keep it all in shape and in contact.

#98

Posted 18 March 2016 - 10:22 AM

Bit of Satin paint over that and will look fine mate. Coming on nicely now.. See you on Monday..

#99

Posted 18 March 2016 - 10:55 AM

Wow, lots of useful jobs done ![]()

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users