So... This took longer than it should've.

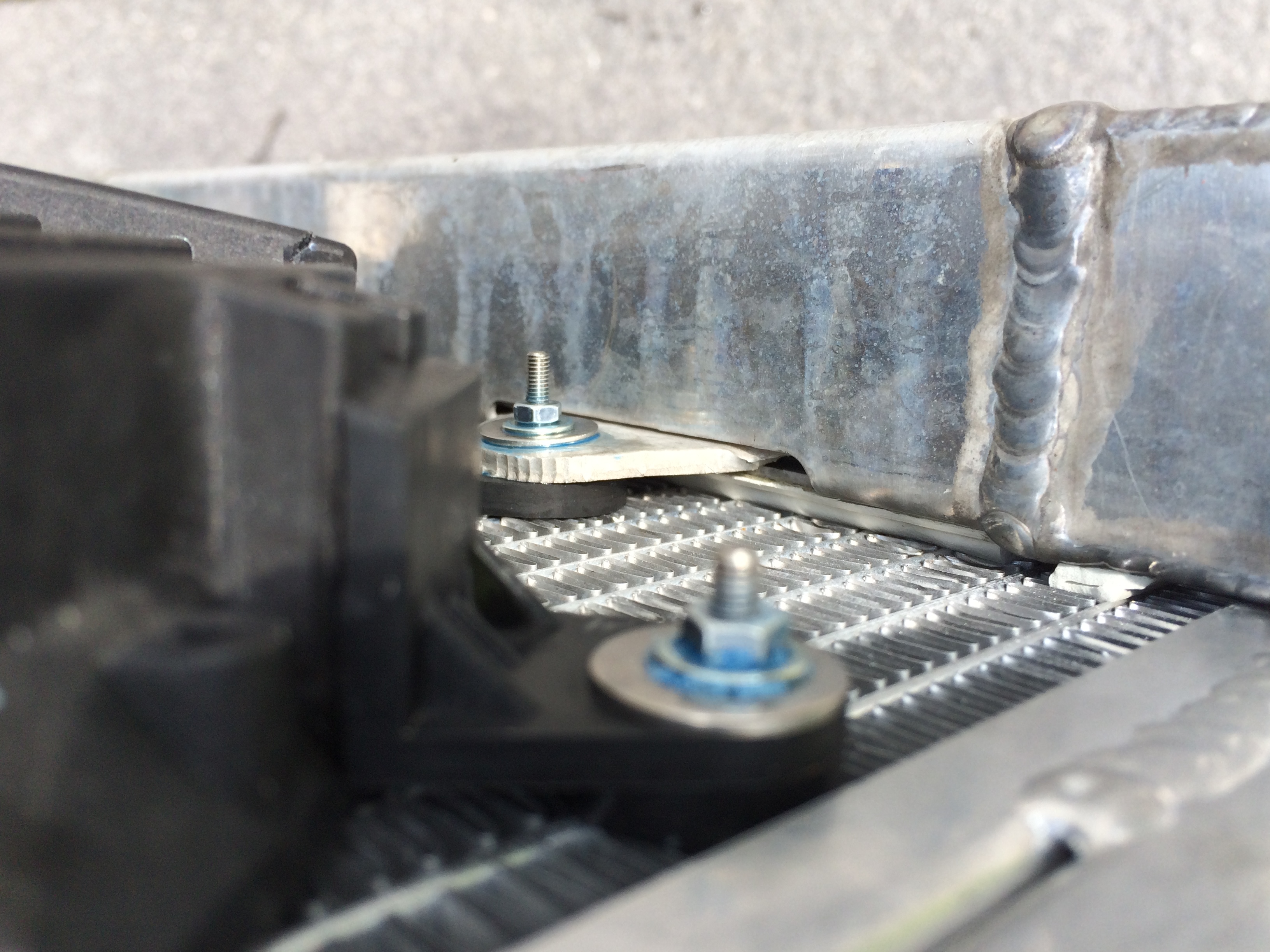

Basically only had to demount the ShinzenCo fans, mount the 10" Spal, and mount the IC cooler and its 8" fan. Problems popped up with how the 8" fan sat on the cooler core, fouling the crashbox. Not helped by how goddamn thick the new radiator is. So I had to rethink how I was mounting the IC cooler altogether. I ended up mounting the 8" on the top of the main radiator (flipping the fan blade turning it from push to pull). I actually still managed to line up the fan mounts on the IC cooler, so the fan sits correctly over the core, now just with a 56mm rad core sandwiched in between. Getting that all lined up top and bottom so the IC core and fan didn't foul stuff was a bunch of fun.

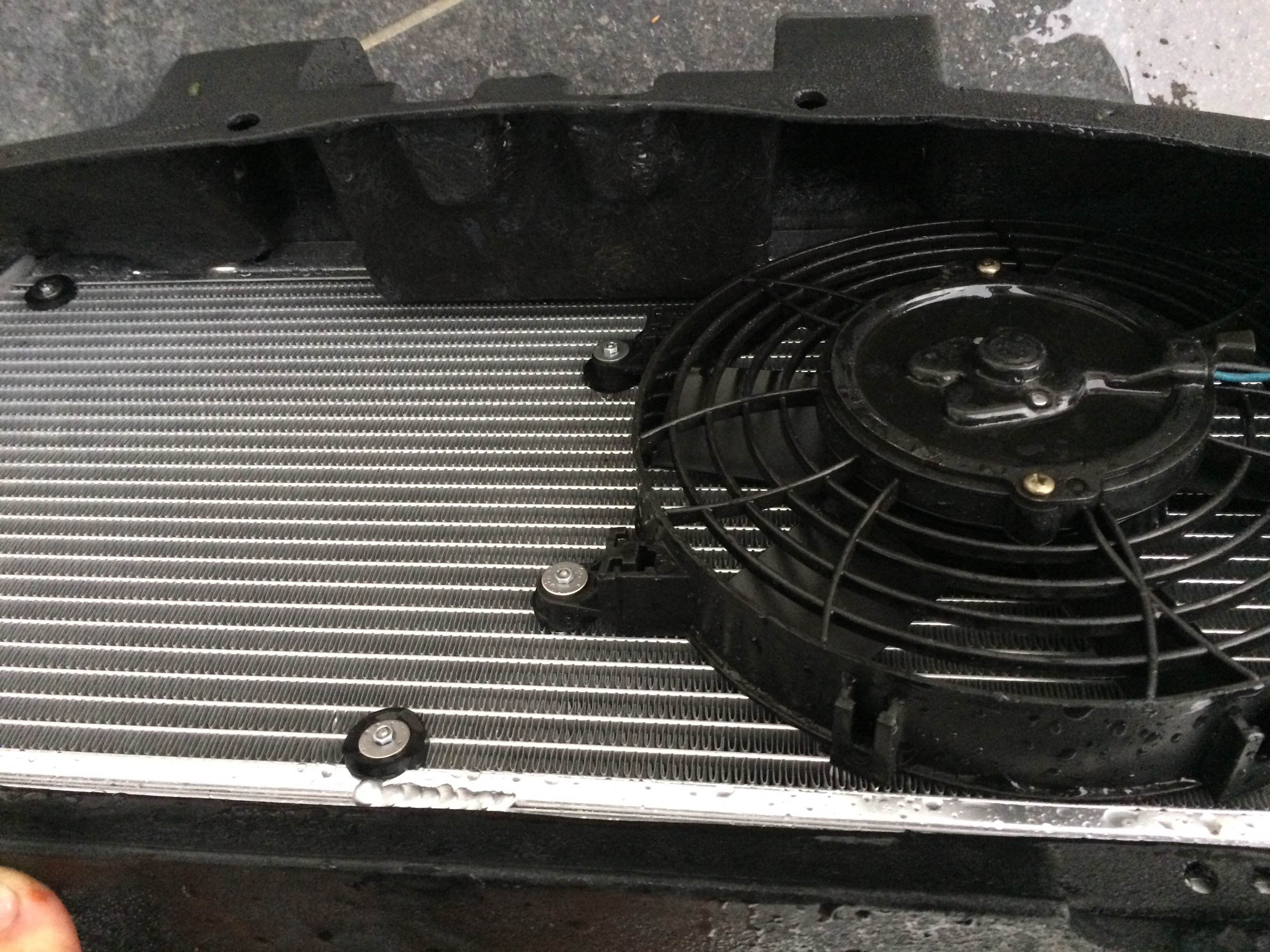

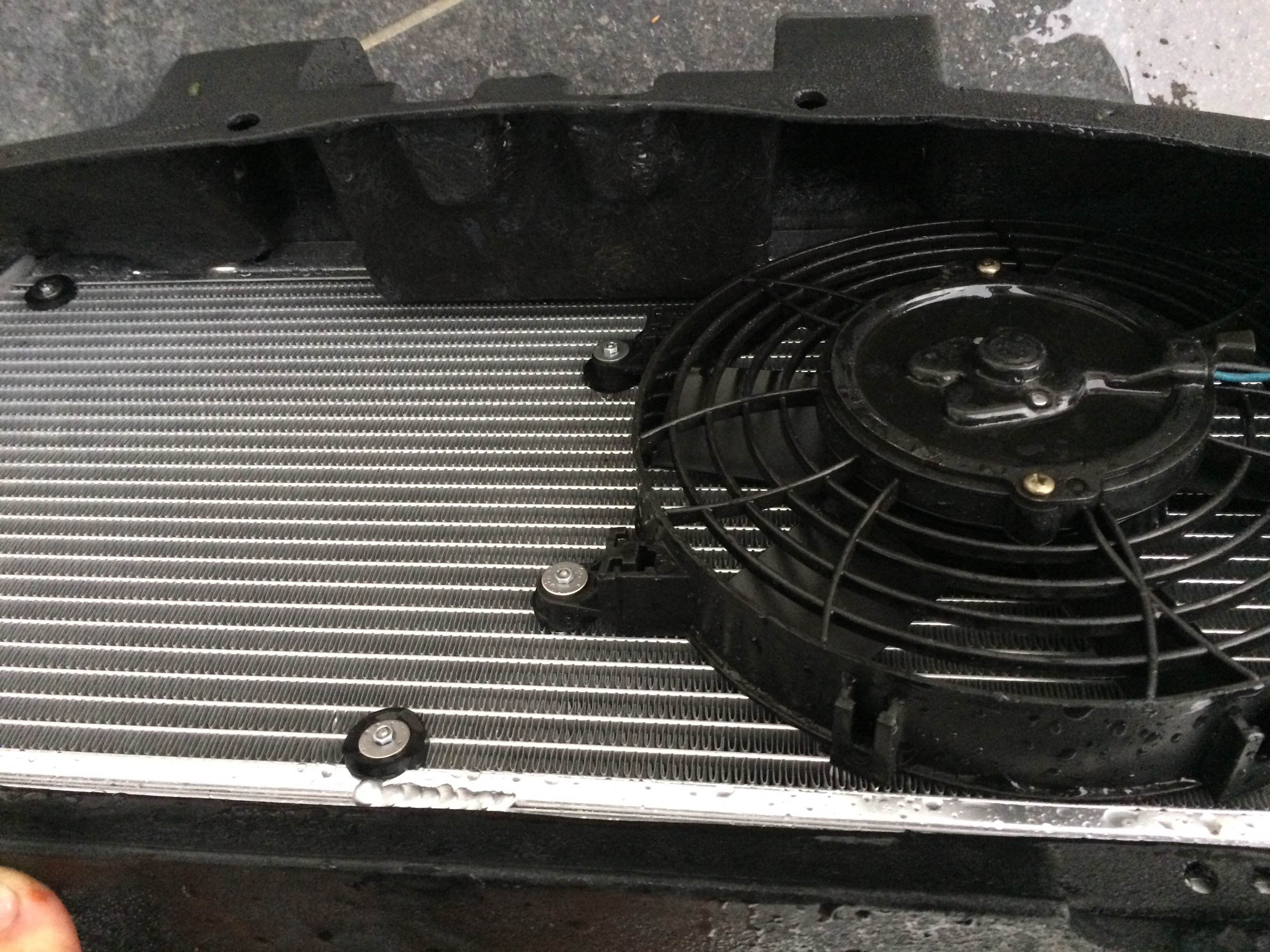

Anyway, couple of pics below. Rad core dwarfs the IC core now. Not that it was particularly big to begin with, but now looks tiny. Also a decent shot there showing exactly how much the new rad fills the surround to the brim.