http://www.der-graue...en/kba70142.pdf

Now everyone talks about the vx being a Corsa B setup, so looking at that cert above, that would be a 6607 hub. Now it's probably worth noting that every single damn Vauxhaull of the late 90s runs a 6605 hub, and the Corsa B is literally the only model which uses the 6607.

But I thought I'd trust the crowd and go for the Corsa B unit...

...doesn't work

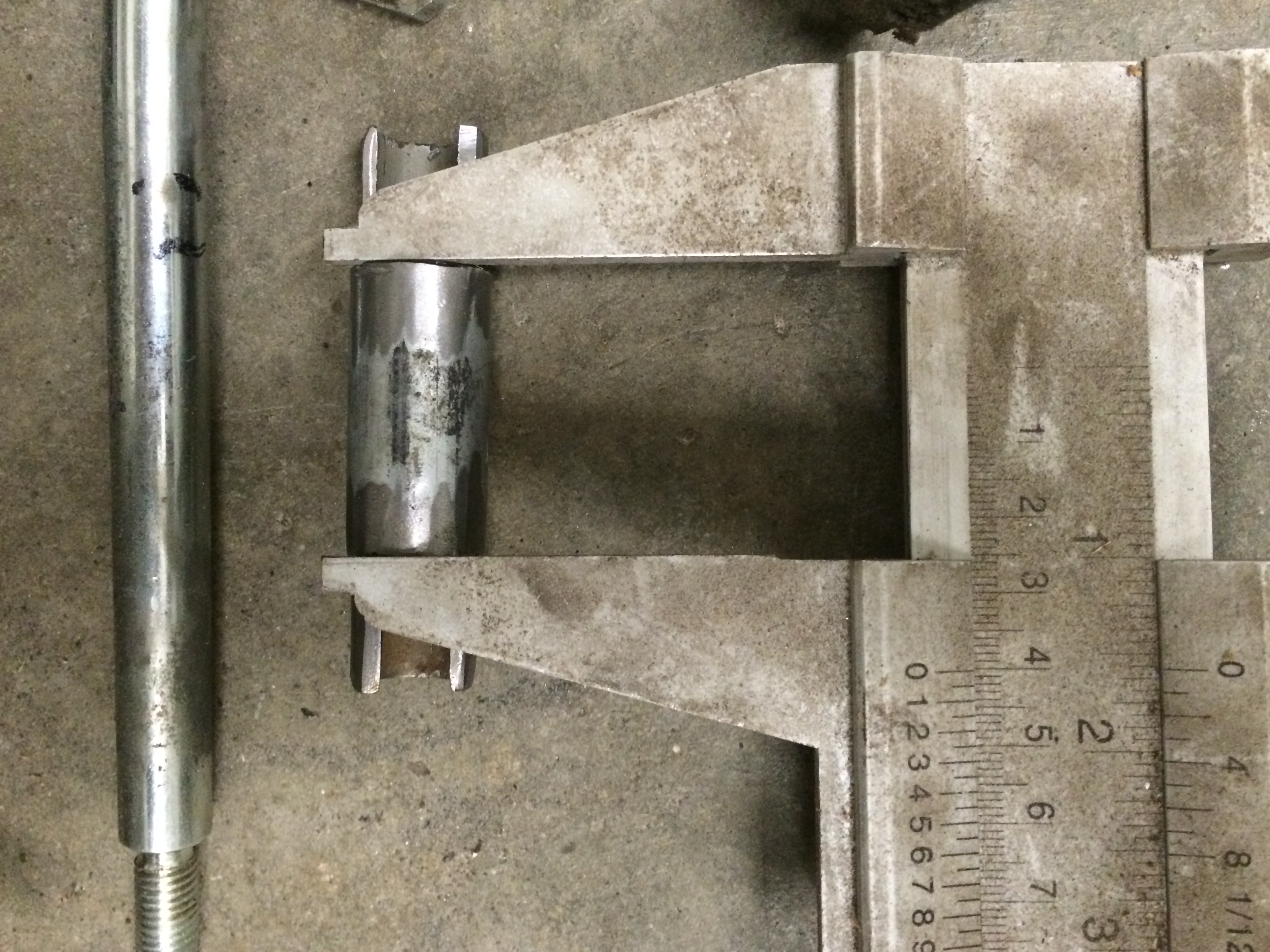

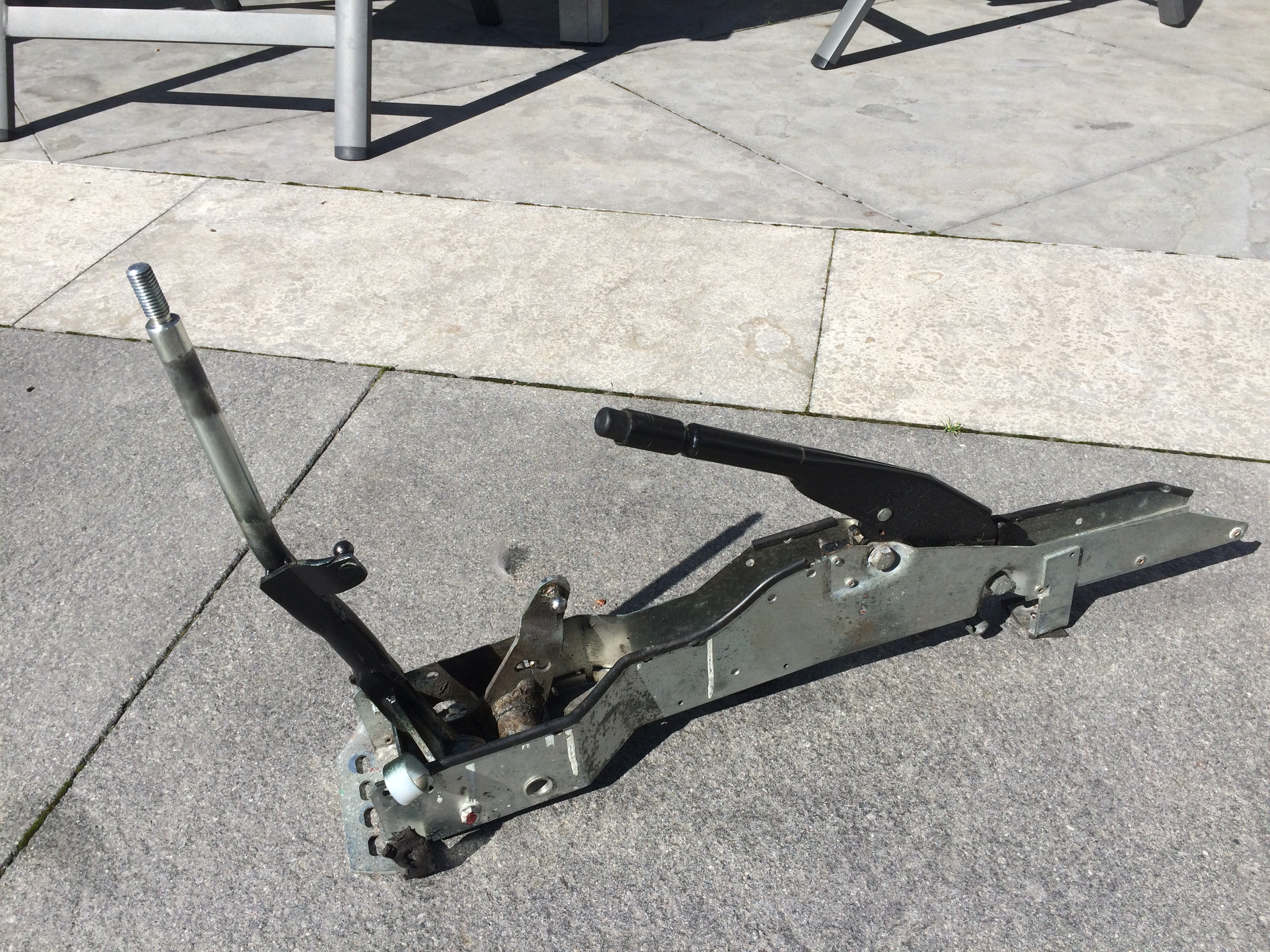

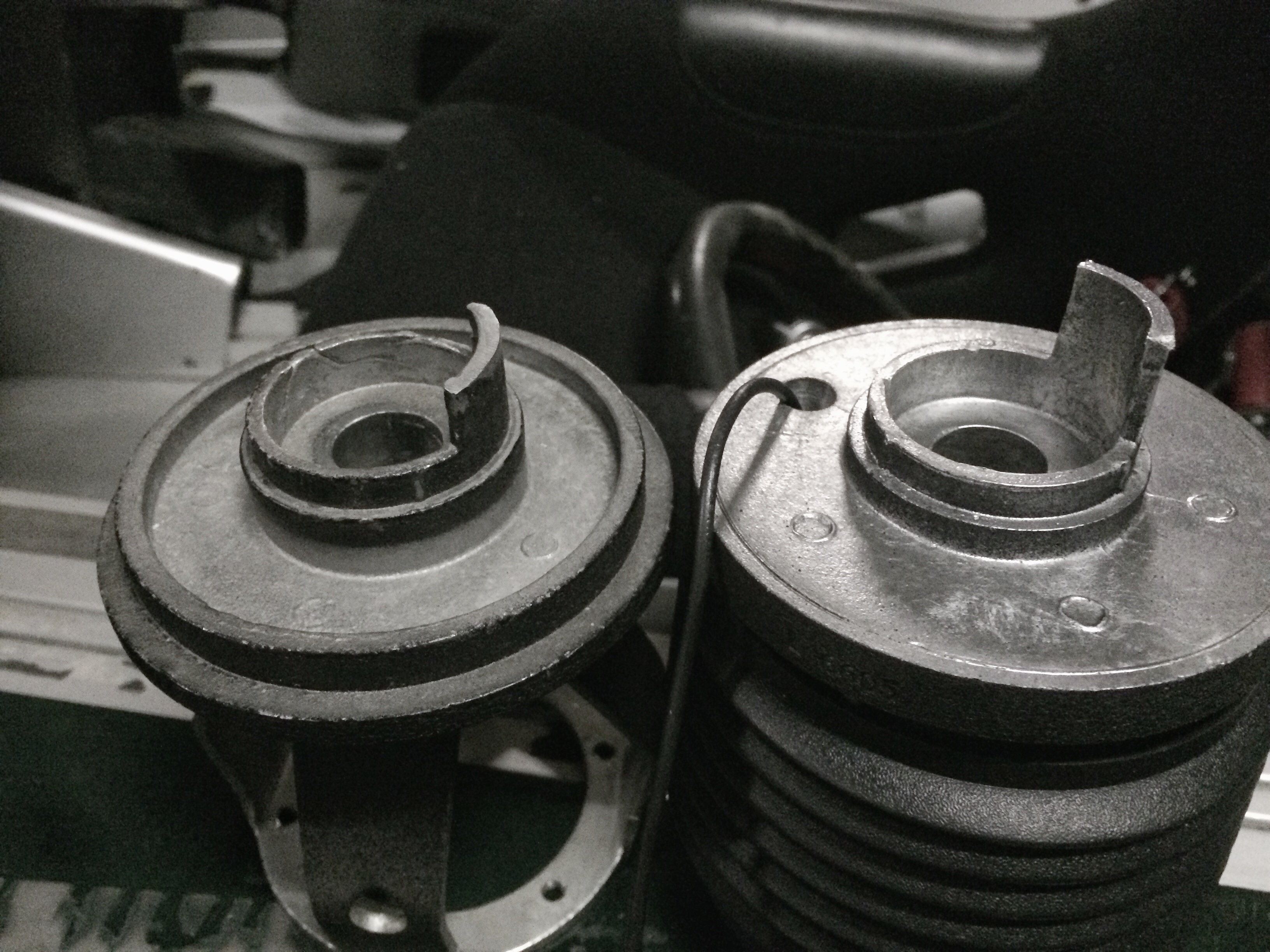

Basically the indicator cancel tab on the 6607 is too short to reach the mechanism. So I stumped up and bought a 6605 hub. Lo-and-behold this sucker fits and works just fine. So 6605, for a Corsa A/C or practically any other Vauxhaull of the period. (L or C prefix signifies a medium or long hub, I got the L6605)

above - 6607 on left. 6605 on right. The 6607 has the shorter indicator tab, and doesn't reach the mechanism

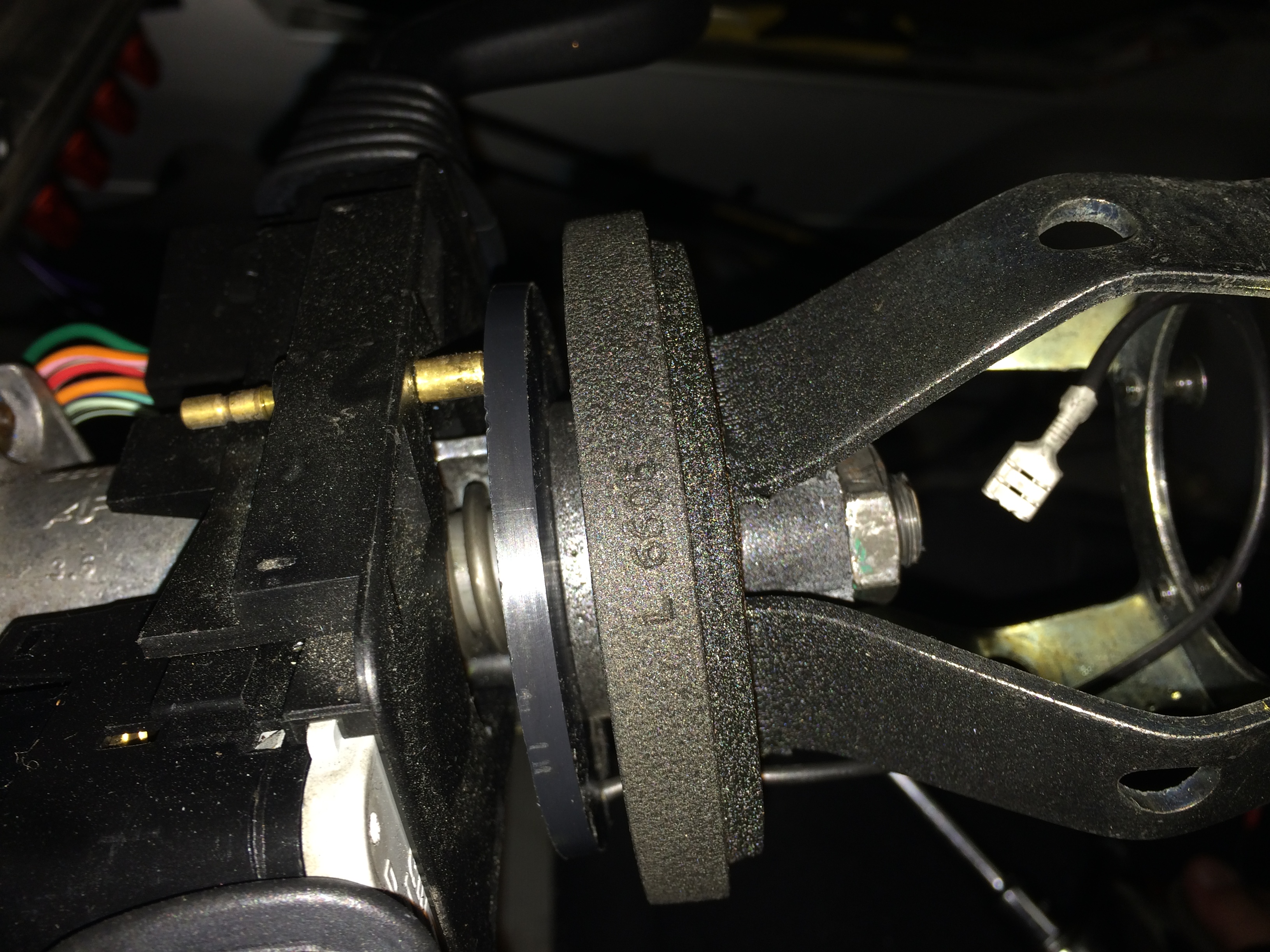

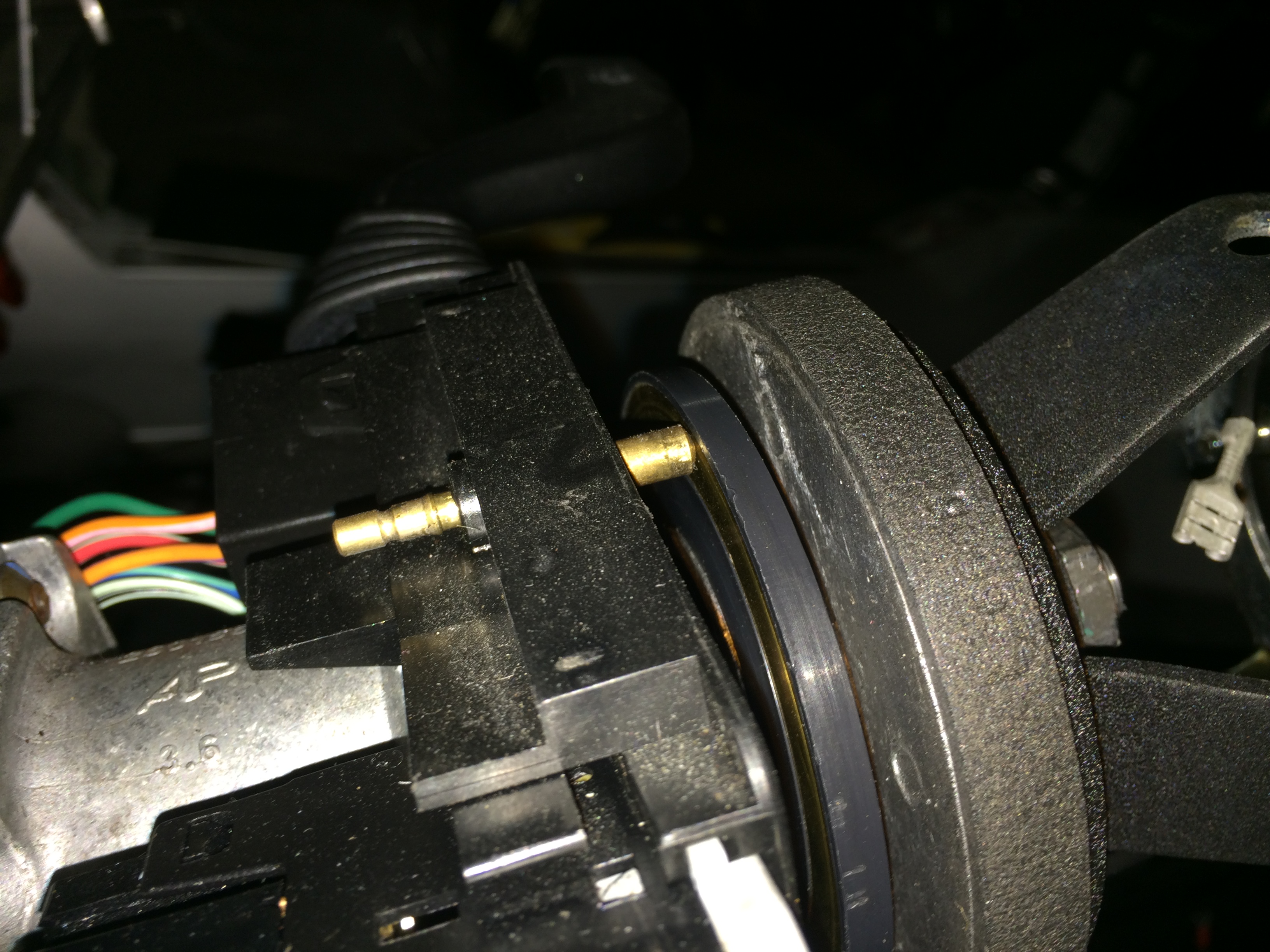

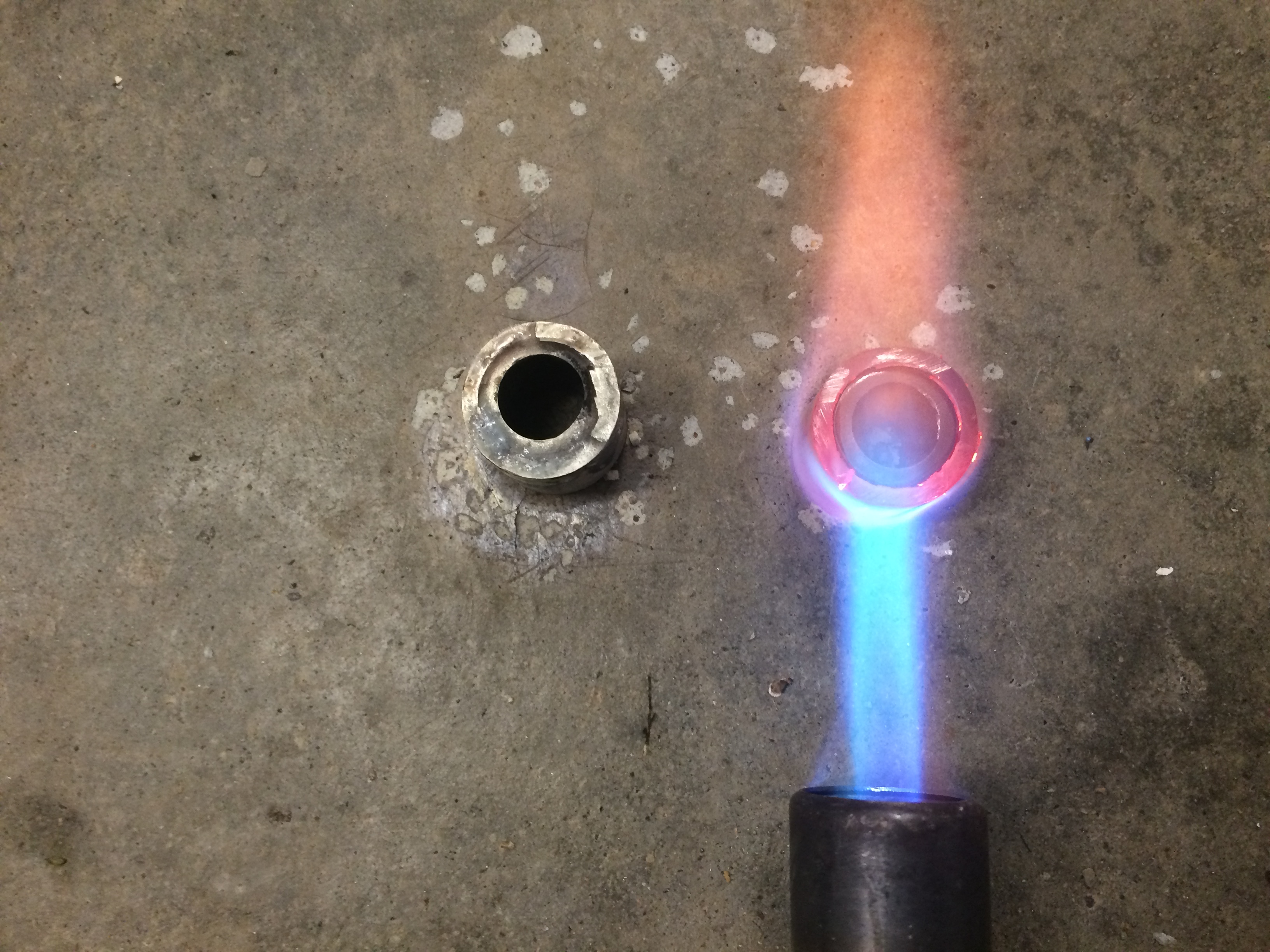

Of interest to players at home, it's interesting that the vx steering column came fitted with an airbag and associated squib/slip ring assembly. As I pulled it apart I thought it was weird how that assembly was held in: indexed in position by this random spring loaded brass pin... lol... Vauxhaull just used some old non-airbag column assembly with traditional slipring setup in place, left the pin in, and made the squib fit over the top, roughly repurposing the pin. Pretty lazy engineering, but it makes retrofitting back to a non airbag aftermarket slipring setup remarkably easy!