Posted 30 October 2017 - 08:07 AM

Posted 31 October 2017 - 12:07 PM

Edited by Doctor Ed, 31 October 2017 - 12:16 PM.

Posted 31 October 2017 - 12:22 PM

Posted 31 October 2017 - 04:23 PM

the guy I bought the LSD from said the bigger bearings and extra oilways on the improved M32 casing do nothing, they still fail.

He said run 3.5 litres of oil and it will never fail again. I am now running three litres of OEM LSD gearbox oil with the original size bearings and end casing (I have the improved casing and bigger bearings sat on the shelf)

Posted 31 October 2017 - 07:13 PM

Edited by Doctor Ed, 31 October 2017 - 07:21 PM.

Posted 01 November 2017 - 10:51 AM

Edited by Doctor Ed, 01 November 2017 - 10:56 AM.

Posted 16 November 2017 - 08:25 PM

Posted 21 November 2017 - 06:29 PM

Posted 21 November 2017 - 07:11 PM

Are you going to do a V-band adaptor for the 4-bolt turbine outlet? Just curious..

Coming along nicely BTW!

Posted 21 November 2017 - 07:19 PM

Thanks! Yep, 3.5" V band onto the turbine flange (maybe 1" of tube in between for clearance to the flange bolts)Are you going to do a V-band adaptor for the 4-bolt turbine outlet? Just curious.. Coming along nicely BTW!

Posted 22 November 2017 - 05:06 PM

Posted 22 November 2017 - 08:26 PM

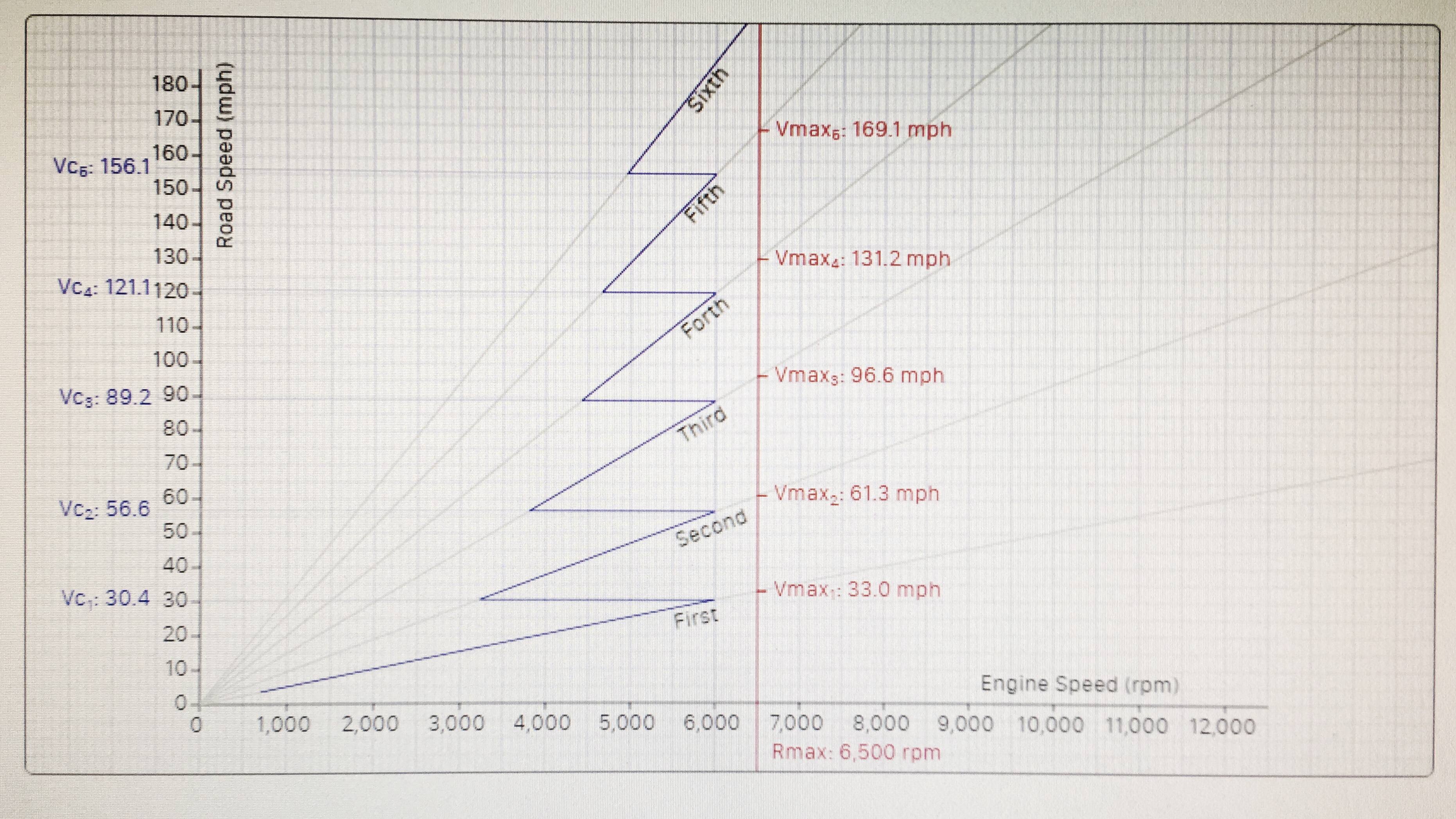

I used to think tall gears were the way ahead, but now think the opposite. I hardly use 5th in anger as it's so long with 3.65 final drive.

You sound like a man who knows his plan, but I'd consider lower ratios if I were you...

Posted 22 November 2017 - 09:11 PM

Posted 23 November 2017 - 07:06 AM

Posted 23 November 2017 - 08:38 AM

Edited by Doctor Ed, 23 November 2017 - 08:39 AM.

Posted 23 November 2017 - 10:04 AM

Edited by Doctor Ed, 23 November 2017 - 10:05 AM.

Posted 23 November 2017 - 10:25 AM

F*ck me, that is mental. Did the seller claim it was in "good working order"??

It looks as bad as as the "well maintained" VX220/gearbox that Glen Wood bought off Martin.

Edited by Nev, 23 November 2017 - 10:26 AM.

Posted 23 November 2017 - 10:25 AM

That's a reasonably impressive bit of gear wear there..

RTS for that one!

Posted 23 November 2017 - 10:37 AM

Posted 23 November 2017 - 12:24 PM

Edited by Doctor Ed, 23 November 2017 - 12:24 PM.

0 members, 1 guests, 0 anonymous users