Looks good, have put their company website in my favourites. Ta.

Project Fracas - 6Sp A20Nft

#801

Posted 22 December 2017 - 01:36 PM

#802

Posted 22 December 2017 - 09:49 PM

in dont have anything to do with those blokes but they seriously deserve the kudos. really top work, top service. benchmark stuff.

#803

Posted 23 December 2017 - 03:40 PM

#804

Posted 31 December 2017 - 03:35 PM

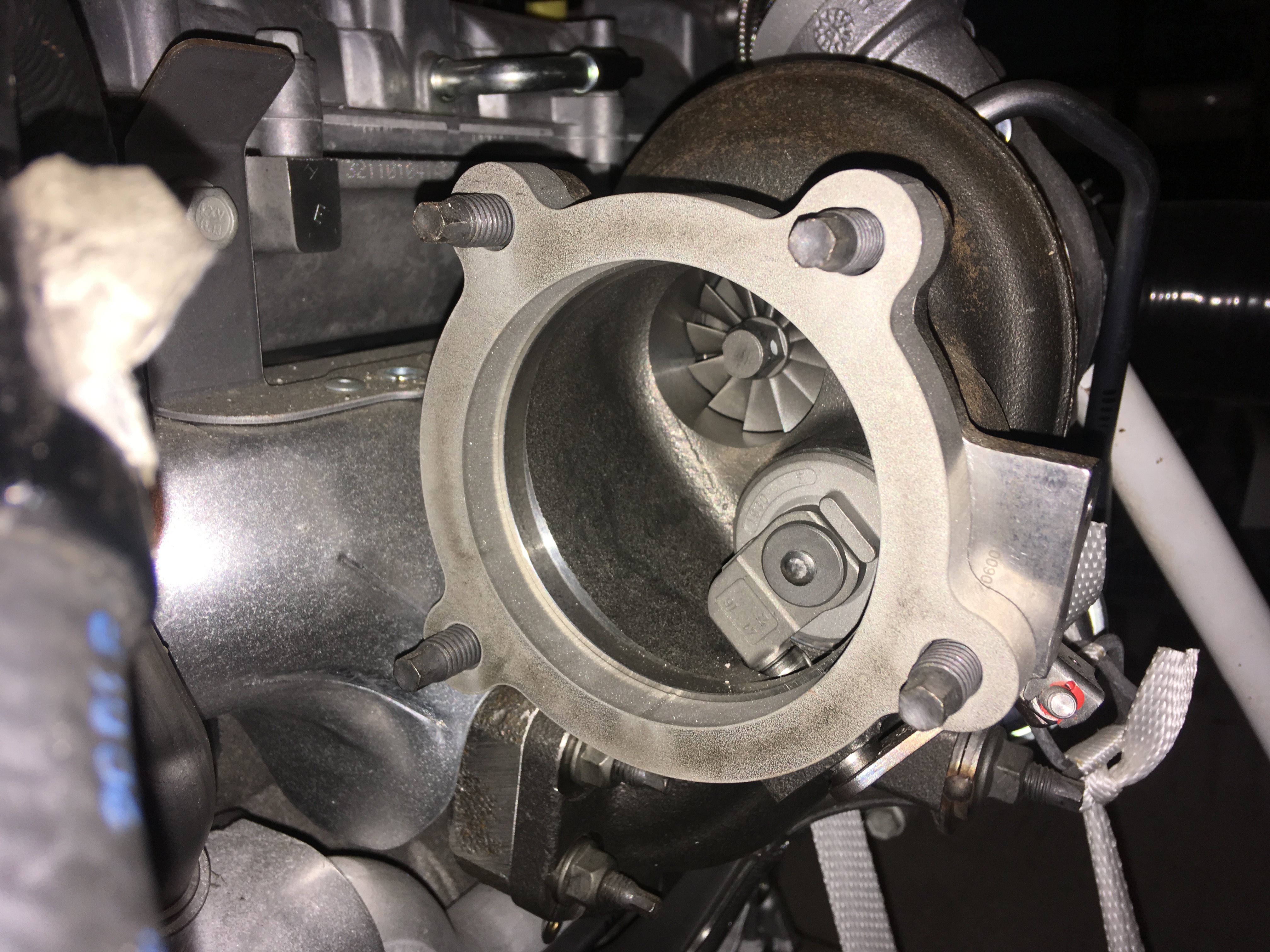

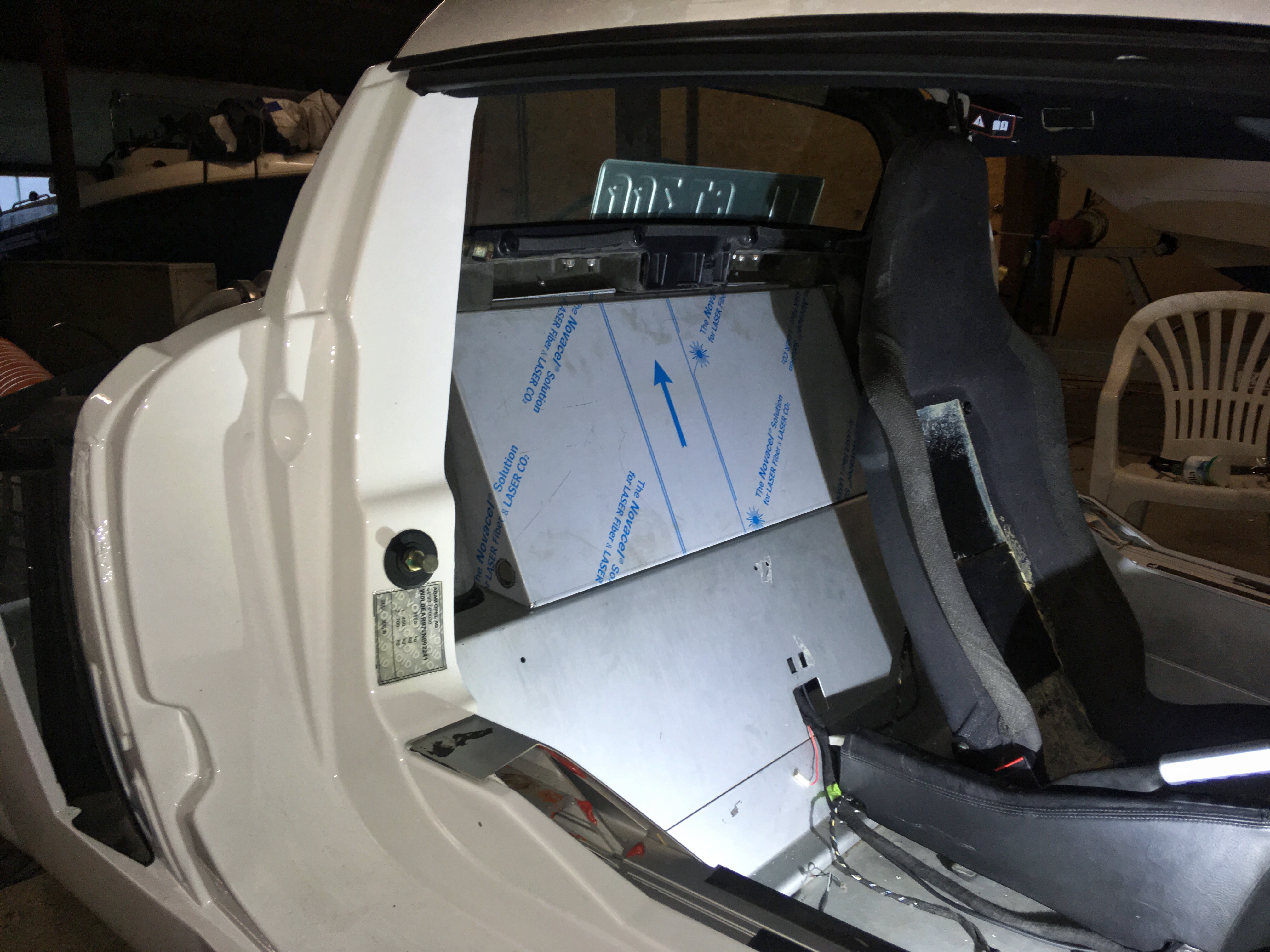

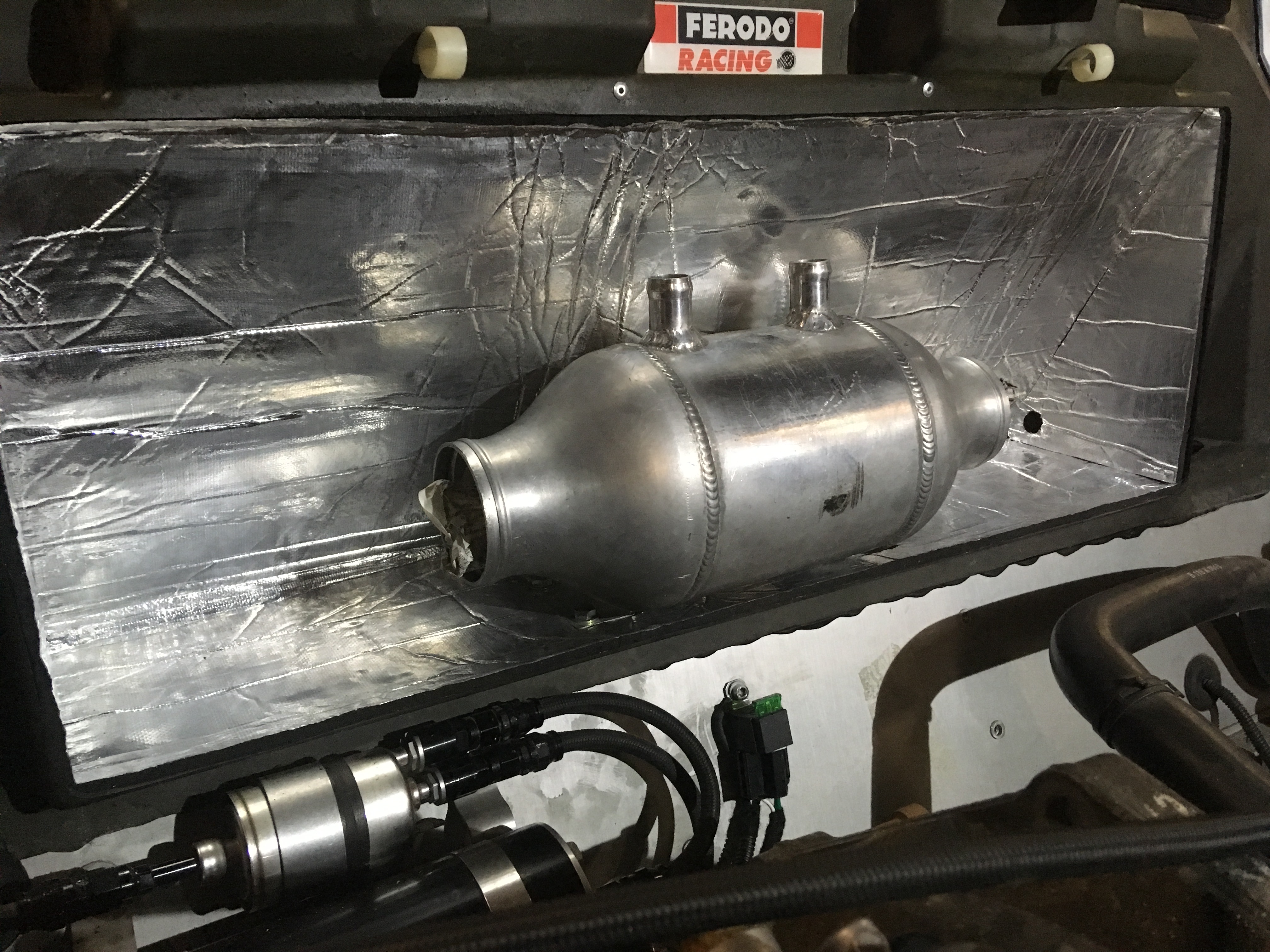

sits in pretty well actually, quite happy how it worked out, and didnt get sikafelx absolutely everywhere

#805

Posted 31 December 2017 - 04:38 PM

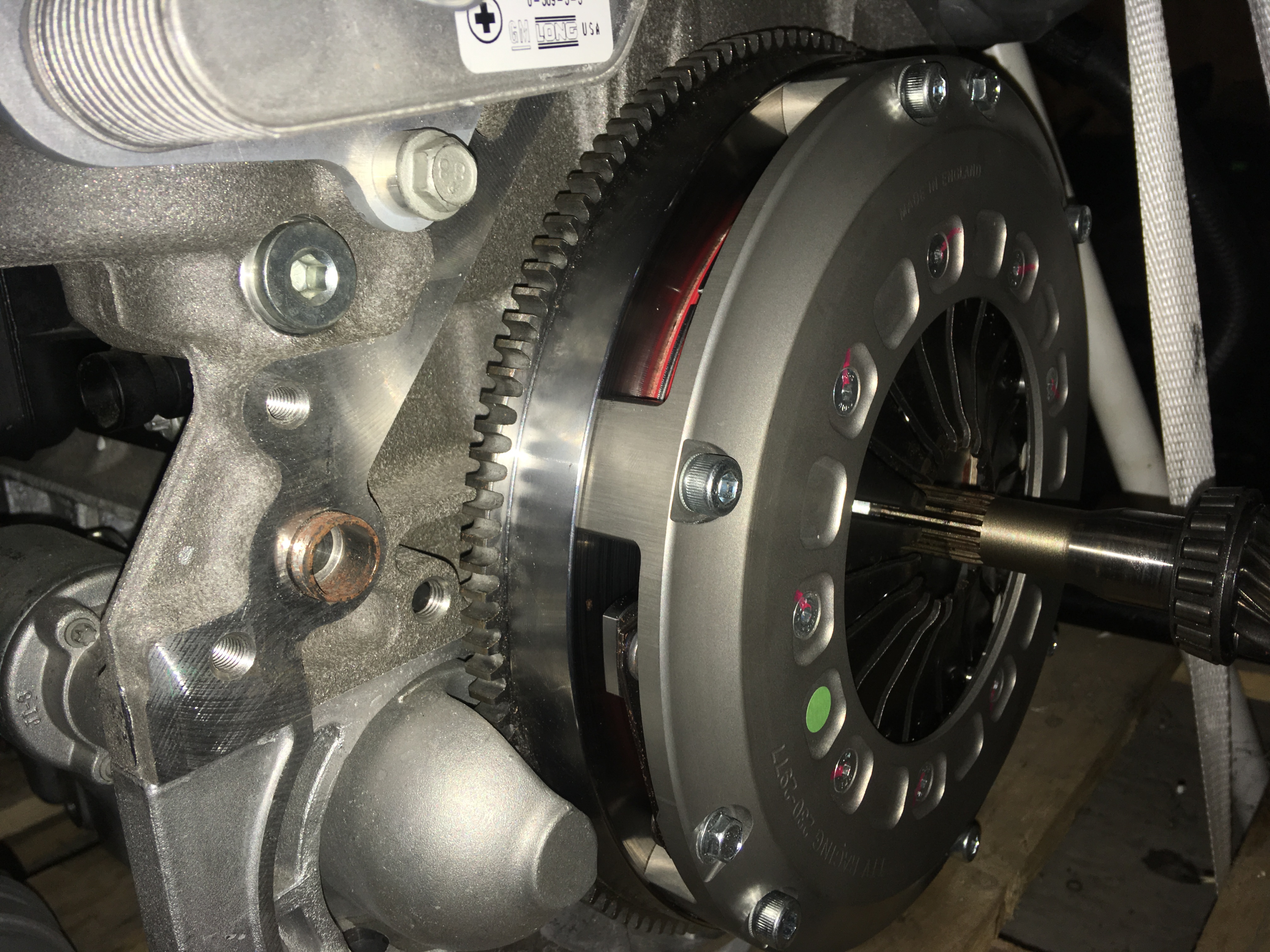

What clutch is that ?

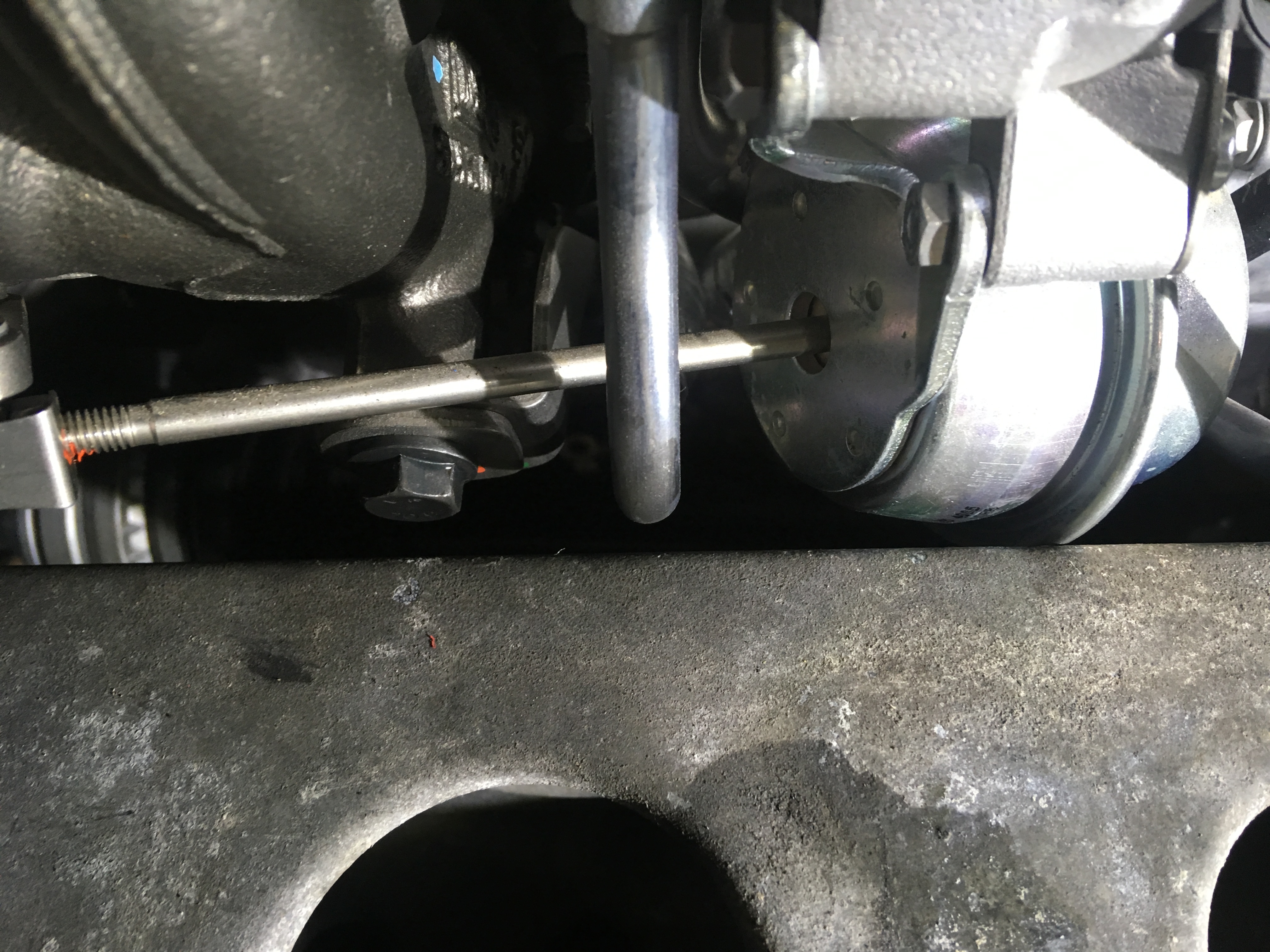

ARPs lubed, loctited, and torqued

#806

Posted 31 December 2017 - 04:58 PM

#807

Posted 24 January 2018 - 11:40 PM

#808

Posted 25 January 2018 - 11:47 AM

Good work as always and fair progress. ![]()

Great place for the intercooler, I bet your charged air run is nice and short.

Everything looks so clean and orderly in these new/rebuild threads, looking into my engine bay isn't like that any more - that's for sure.

Edited by Nev, 25 January 2018 - 11:47 AM.

#809

Posted 10 February 2018 - 01:10 AM

#810

Posted 10 February 2018 - 01:11 AM

#811

Posted 10 February 2018 - 06:05 AM

#812

Posted 10 February 2018 - 08:39 AM

Edited by Doctor Ed, 10 February 2018 - 08:46 AM.

#813

Posted 10 February 2018 - 08:43 AM

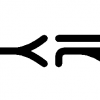

You should try and rotate it or fit a smaller actuator, using a hammer is not advised ![]()

#814

Posted 10 February 2018 - 08:51 AM

#815

Posted 10 February 2018 - 09:11 AM

Looking good i can't see a problem with a little hammering myself .Sorry if its been asked what power are you going for ?

#816

Posted 10 February 2018 - 09:46 AM

Edited by Doctor Ed, 10 February 2018 - 09:55 AM.

#817

Posted 10 February 2018 - 09:50 PM

#818

Posted 10 February 2018 - 10:42 PM

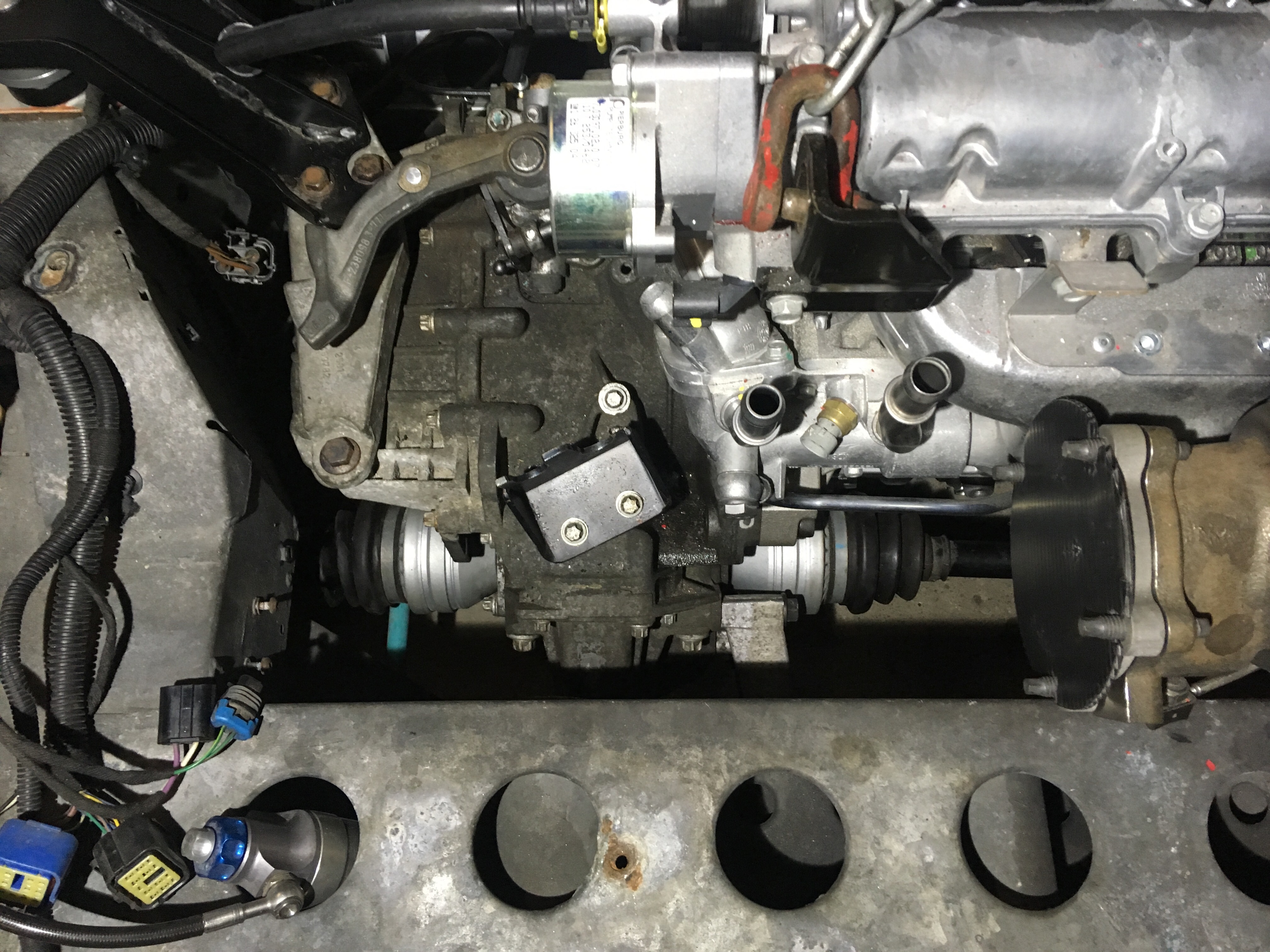

So, to quickly summarise the bits making this work

- A20NFT 2L DI Turbo (Ecotech/B207 family)

- M32 6Sp Box from some 2.2L Opel/Vauxhall

- Europa S left/right motor mounts

- Europa S front/rear torque mounts

- Europa S driveshafts

- Tesla Roadster uprights (first car in space!)

- SKF Hubs

#819

Posted 11 February 2018 - 03:18 PM

Edited by piwo, 11 February 2018 - 03:19 PM.

#820

Posted 11 February 2018 - 05:23 PM

yep, looks similarly tight!

intercooler is a PWR W2A - i cut and moved the firewall to fit it in front of the motor. see pics at the top of the page, or heres one:

3 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users

-

Bing (2)