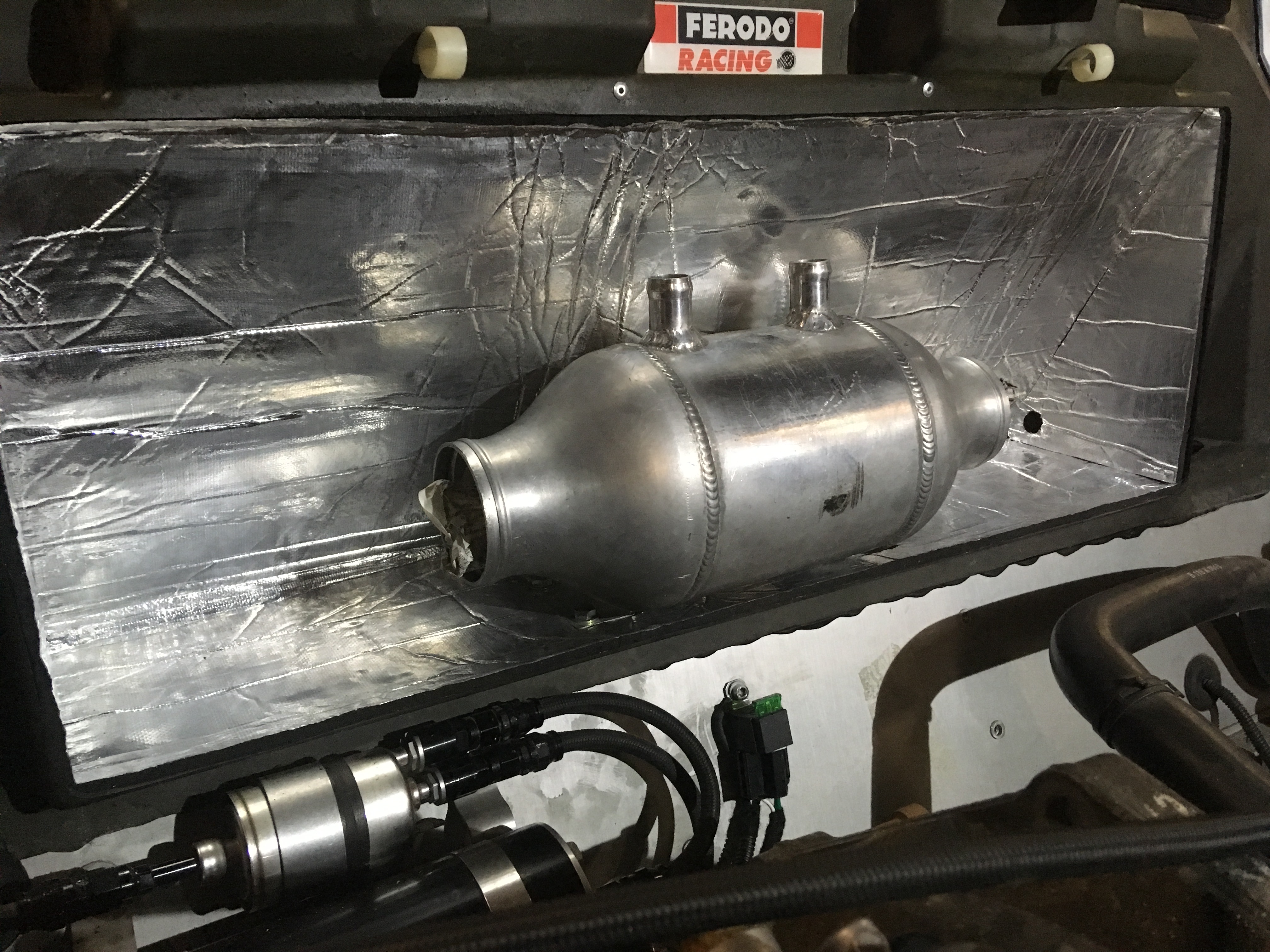

Well organized machine room. You're clearly trying to copy the OEM look ![]() That 180 degree silicone bend from the chargecooler to the TB has enough play to allow for the rocking of the engine I assume. I copied you're idea with the firewall and it even looks like I'm using the same chargecooler (6x6 inch PWR) and as I have to be concerned about something, my latest concern is about finding some play in the charge cooling tubing (more correctly: hosing) to allow for the rocking of the engine. Here it looks like the material itself provides more than enough flexibility.

That 180 degree silicone bend from the chargecooler to the TB has enough play to allow for the rocking of the engine I assume. I copied you're idea with the firewall and it even looks like I'm using the same chargecooler (6x6 inch PWR) and as I have to be concerned about something, my latest concern is about finding some play in the charge cooling tubing (more correctly: hosing) to allow for the rocking of the engine. Here it looks like the material itself provides more than enough flexibility.

Project Fracas - 6Sp A20Nft

#881

Posted 06 April 2018 - 09:55 AM

#882

Posted 06 April 2018 - 11:28 AM

#883

Posted 06 April 2018 - 12:39 PM

If you're worried about the movement you could always install something like:

![]()

https://www.autospor...low-143641.html

That takes up the movement. Reinforcement means it doesn't inflate.

Bye, Arno.

#884

Posted 06 April 2018 - 02:30 PM

Yep, exactly. The silicone bends to/from the intercooler core serve as the flex joints for engine movement. Did you get the firewall cut already? Howd it fit up?

Yes, it's in. There was a gap on the top. Issue was that the topside is a bit curved, so there was a gap in the middle, with the corners fitting perfectly. I used an aluminum L-profile and kit to close that gap. And I had to make a small hatch as the -enlarged- access to the fuel pump got partly covered. In general I great idea to add some space in a critical area however.

@Arno, I was planning to use a bump hose (looks like a python that swallowed a sheep) instead of a bellows. The bump hose allows for 20 degrees of rotation in all directions. But it may be that the material itself has enough flexibility. In my case the outlet of the SC may be very close to the inlet of the chargecooler, in which case I have to get creative

#885

Posted 06 April 2018 - 04:47 PM

Can see the rivets at the top

Edited by Doctor Ed, 06 April 2018 - 04:49 PM.

#886

Posted 06 April 2018 - 09:01 PM

#887

Posted 06 April 2018 - 11:29 PM

for my own sanity, i just checked, and i did mention the line of the top cut in a PM: "[color=rgb(40,40,40);font-family:helvetica, arial, sans-serif;]Bulkhead you can basically cut out flush to the edges at the sides, and from the upper corners cut it out in a straight horizontal line across the top"[/color]

[color=rgb(40,40,40);font-family:helvetica, arial, sans-serif;]all good though, sounds like it all went in and fit up well ![]() [/color]

[/color]

#888

Posted 07 April 2018 - 08:18 PM

#889

Posted 07 April 2018 - 09:33 PM

#890

Posted 08 April 2018 - 07:30 AM

#891

Posted 08 April 2018 - 03:55 PM

#892

Posted 08 April 2018 - 05:54 PM

that is a neat solution ![]()

#893

Posted 10 April 2018 - 06:39 AM

- sort out main coolant hoses in the engine bay (plus T-fittings, expansion tank circuit etc)

- intake pipework inc dodgy hummer filter

- intercooler pipework

- exhaust pipework

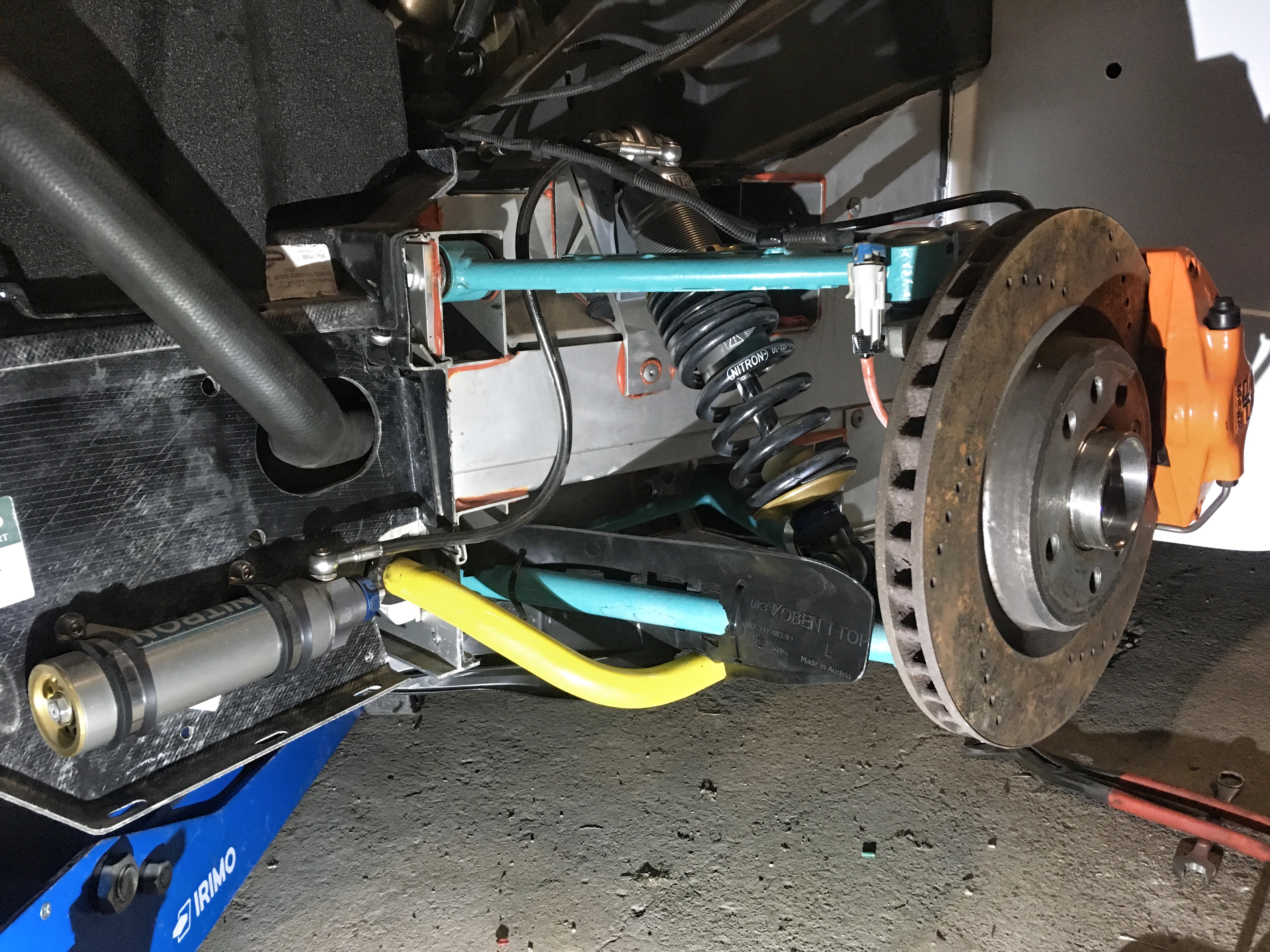

- hook up fr and rr brake lines

- fill and bleed brakes and clutch

- make new gearbox cable mount (5mm too short!)

- make new header tank bracket

Small fiddly stuff:

- finish routing the front wiring loom

- make front undertray air deflector panel with small vortex generators

- finish fitting 997 gt3 brake cooling deflectors

- run wire from a dash switch to the exhaust for 'loud valve' control

- tidy up center console area, tuck the wiring away, finish it off.

Medium sized fuckaround stuff:

- sort out the heat exchanger water piping, pump and fittings

- sort out heat exchanger thermostat and fan(s)

- fix small crack I just caused in the rear wheel arch, bugger

- make rearview mirror indicator lights?

Large stuff that i need to do properly:

- bond the rear Firewall back to the rollhoop (need rear stays finished for this tho)

- reweld the fittings for the heat-exchanger Core

For the rollcage guy:

- design and make new rear roll-hoop support stays / rear clam support

- design and make new harness bar

- design and make rear toe link support bar

Random bits down the immediate priority list

- bodywork!

- exhaust loud valve

Things to buy

- new portable soldering iron

- aerocatches/body fasteners

The updated done stuff

To get the motor running:

-

-

-

Small fiddly stuff to do first:

-

-

-

-

-

-

-

-

-

-

-

-

-

Medium sized fcuk around stuff:

-

-

-

-

-

-

-

Large stuff I need to do properly:

-

-

-

-

-

-

Random bits down the immediate priority list :

-

-

-

-

-

-

-

Bought

-

-

-

#894

Posted 14 April 2018 - 10:47 PM

#895

Posted 15 April 2018 - 05:41 PM

... couldve done myself a favour and started with this idea first and save a couple of hours of fcuking around, but whos counting.

Don't forget the forces of entropy are always at work on every man!

Any idea when this thing will be ready to roll?

#896

Posted 15 April 2018 - 10:13 PM

#897

Posted 16 April 2018 - 06:25 AM

so what's the saying? measure 100 times, cut 20? pipe layout idea evolved a bit whilst cutting and mocking up. couldve done myself a favour and started with this idea first and save a couple of hours of fcuking around, but whos counting.

Ah.. The joys of 'figuring stuff out' instead of just being able to bolt-on-and-tweak some bits ![]() Can be frustrating to spend a whole day on a car and at the end be left with a few measely brackets or pipes that should really have taken 5 minutes to make.. But took about a zillion tries to find the best and neatest solution.

And once you have something that you're happy with.. In about 3 months you'll realise there was another option that's better!!

Can be frustrating to spend a whole day on a car and at the end be left with a few measely brackets or pipes that should really have taken 5 minutes to make.. But took about a zillion tries to find the best and neatest solution.

And once you have something that you're happy with.. In about 3 months you'll realise there was another option that's better!! ![]()

Oh well.. Part of doing stuff outside the envelope of 'regular' solutions I guess ![]()

Bye, Arno.

#898

Posted 16 April 2018 - 11:11 AM

pretty much describes building this car - but thats the point really - i need the mental chewing-gum outside of workAh.. The joys of 'figuring stuff out'

#899

Posted 16 April 2018 - 02:47 PM

#900

Posted 16 April 2018 - 05:59 PM

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users