Posted 08 September 2018 - 09:59 AM

Posted 08 September 2018 - 06:56 PM

had 5 mins (after embracing my inner bogan)

Posted 09 September 2018 - 08:23 AM

Posted 13 September 2018 - 08:34 AM

Posted 22 September 2018 - 12:27 PM

Edited by Doctor Ed, 22 September 2018 - 12:27 PM.

Posted 22 September 2018 - 01:17 PM

Edited by Doctor Ed, 22 September 2018 - 01:17 PM.

Posted 22 September 2018 - 03:05 PM

Posted 24 September 2018 - 03:39 PM

Posted 24 September 2018 - 04:33 PM

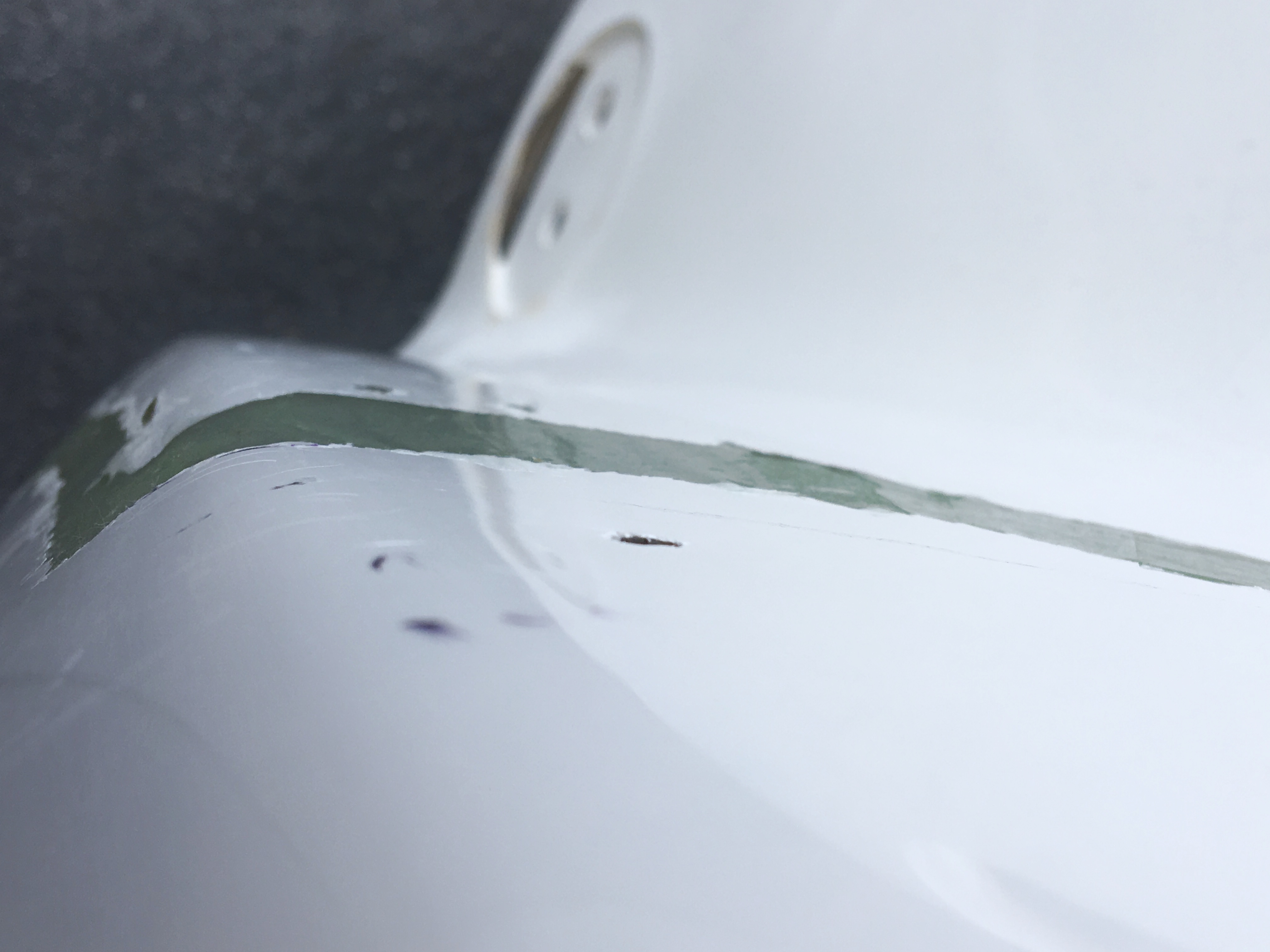

Whats the green coloured filler - epoxy resin?

Posted 24 September 2018 - 06:04 PM

its just polyester resin that's not 100% cured yet (green phase cure)

Edited by Doctor Ed, 24 September 2018 - 06:08 PM.

Posted 25 September 2018 - 07:47 AM

Posted 25 September 2018 - 10:11 AM

yep, fast is not how i would describe it ![]()

Posted 25 September 2018 - 09:14 PM

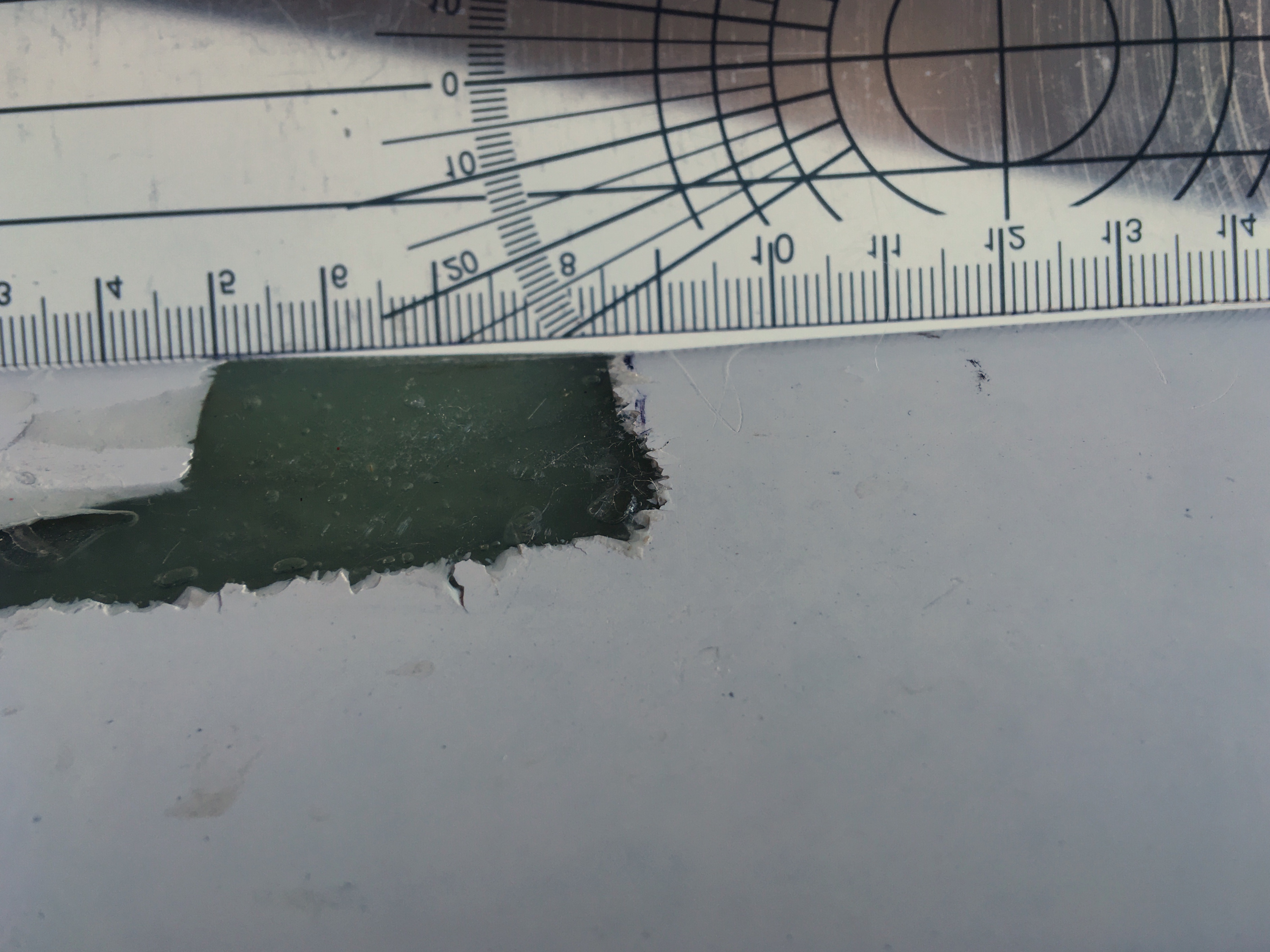

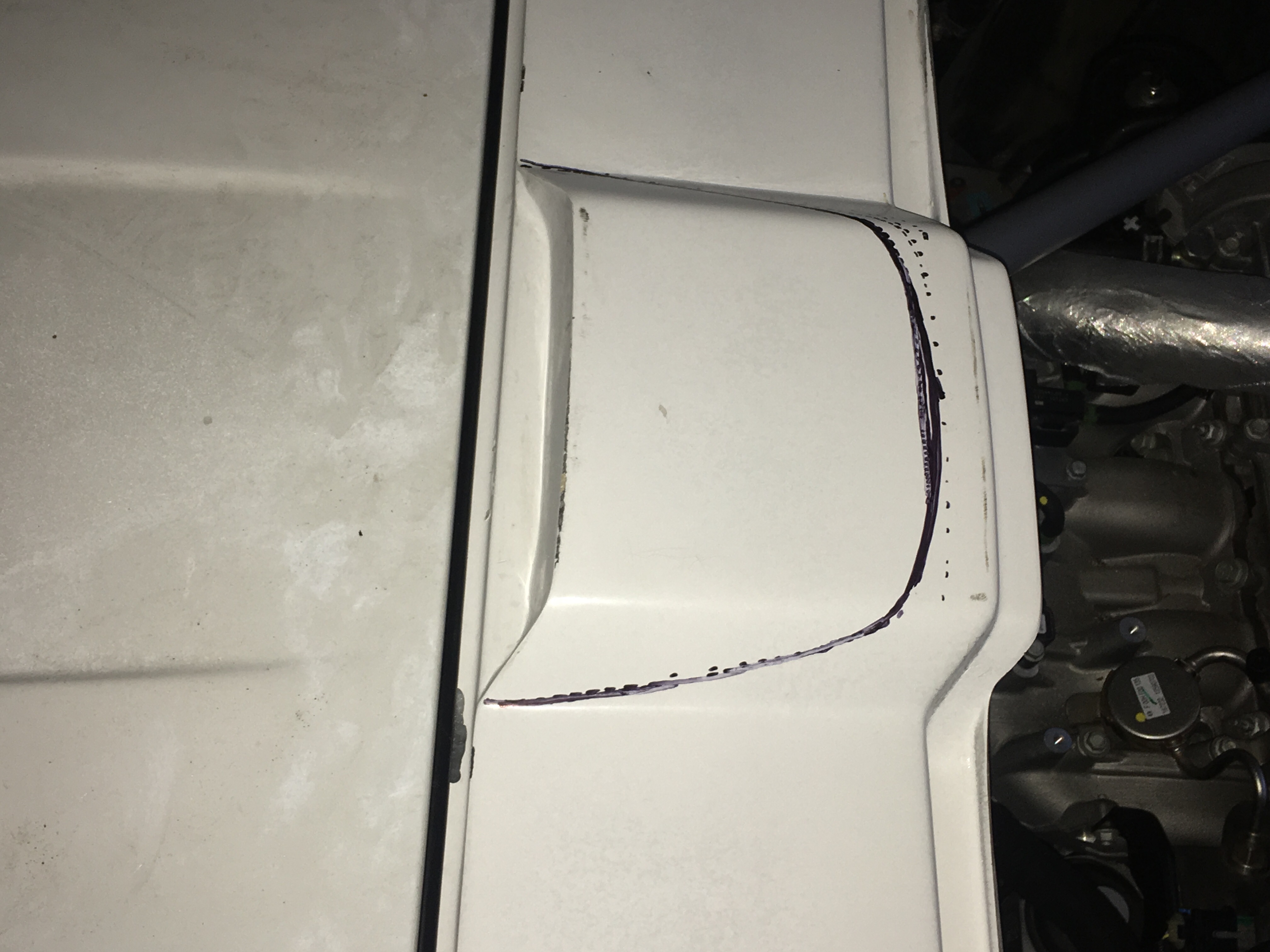

tried something new today... i needed to cut out reprofile 2 big ass holes on each side left over from the dry-break fuel system mounts. again a compound convex curve. so got some relatively thick (~5mm) thermoplastic sheet and the heatgun out. got the basic form of the thermoplastic made based on the section of body immediately next to the hole, then did some minor 'in position' forming to get the contour a little better fitted (tricky as when soft it was easy to let the plastic form into the hole rather than ride flush over it). used hot glue to then seal and hold the thermoplastic form to the surface (releases cleanly and easily from the existing gelcoat).

Edited by Doctor Ed, 25 September 2018 - 09:14 PM.

Posted 26 September 2018 - 10:35 AM

125mm rubber velcro sanding plate on the grinder. pack of 60grit discs, windy day (fcuk you neighbours!) and off we go. ive never sanded fibreglass like this before, and jesus, its amazing. the control is brilliant, the rate of material removal is predictable and very finely adjustable with hand/disc position. and whilst i was initially a bit held back running the disc dead flat on the panel surface (normally a big no-no for me with an angle grinder) holy sh*t *sun ray pieces through the clouds, illuminating me with enlightenment* once the focussed material removal is done with the disc angled into the workpiece, laying it dead flat on the panel surface and moving it in circles like a buffing machine is next level! the rate of removal slows, and it blends complex contours like a fcuking boss. it doesn't flatten anything at all, it rolls the highs and lows and almost instinctively take out unwanted high spots whilst maintaining the curve and profile of the piece in general. such a pleasure to work with.

Posted 26 September 2018 - 11:08 AM

Posted 27 September 2018 - 08:04 AM

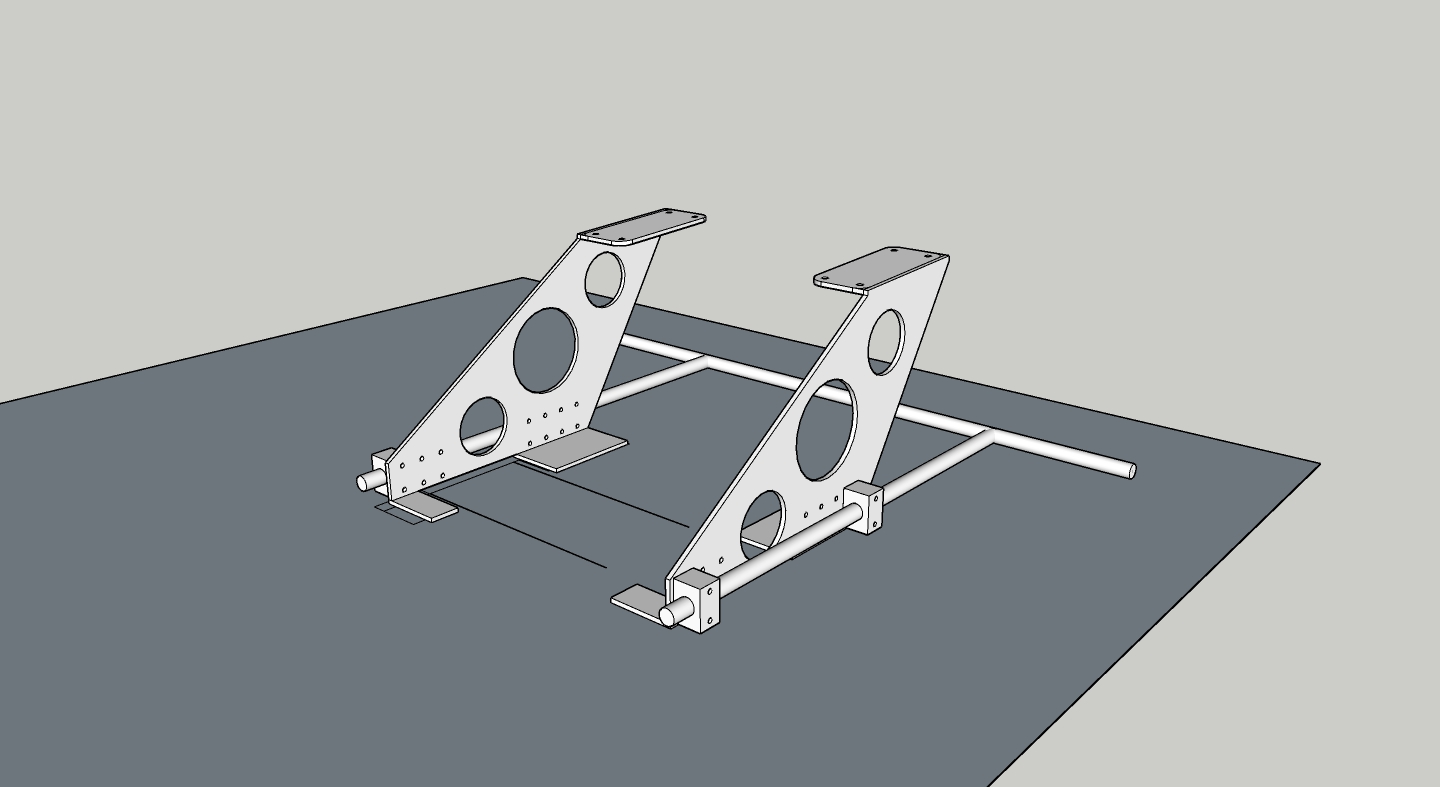

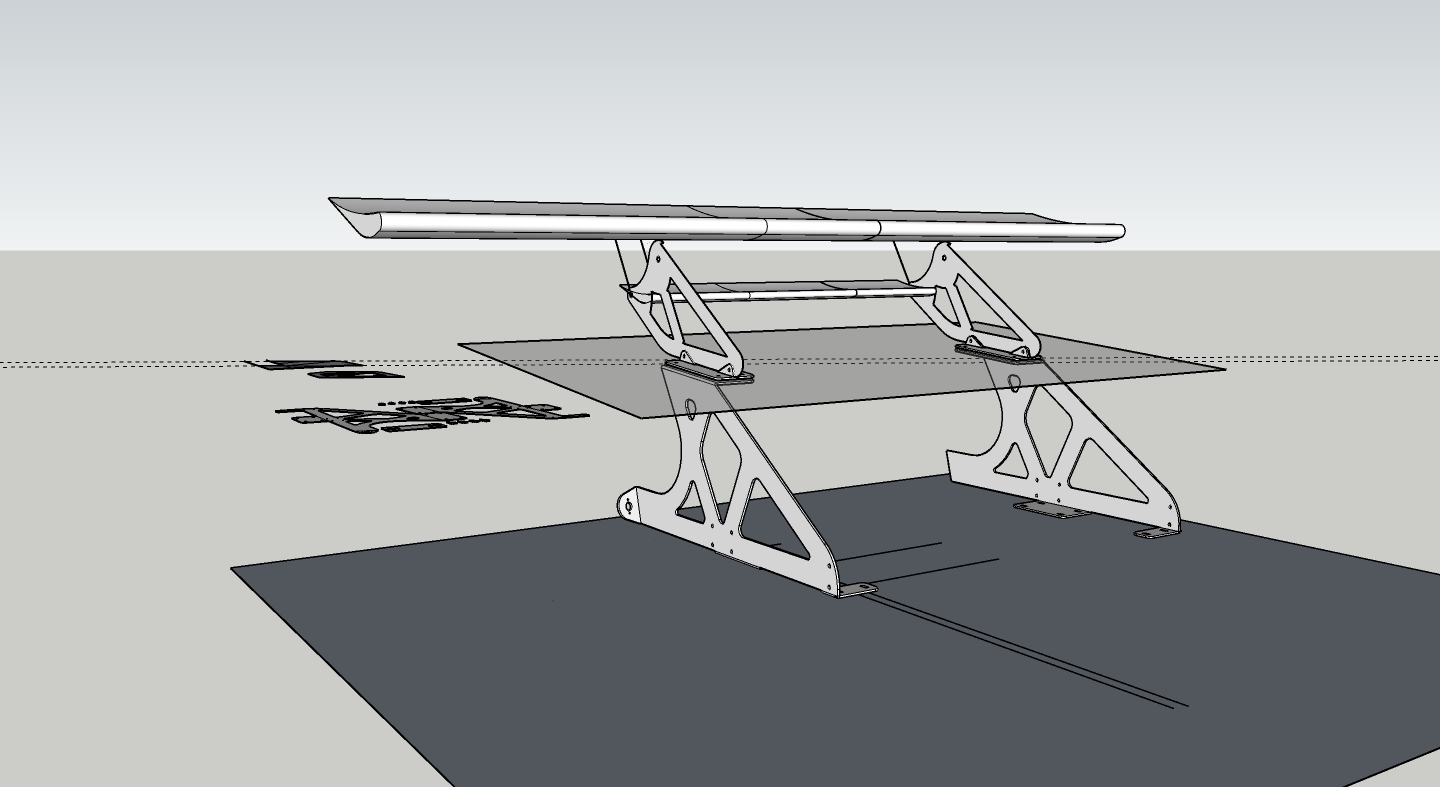

ideas on the wing support structure.

Posted 27 September 2018 - 02:52 PM

Ideal use of garden furniture ![]()

Posted 27 September 2018 - 10:38 PM

Posted 28 September 2018 - 04:10 AM

Posted 28 September 2018 - 05:54 AM

0 members, 1 guests, 0 anonymous users