Not standard

The incandescent rear lights on the S2 were set up from the factory very simply:

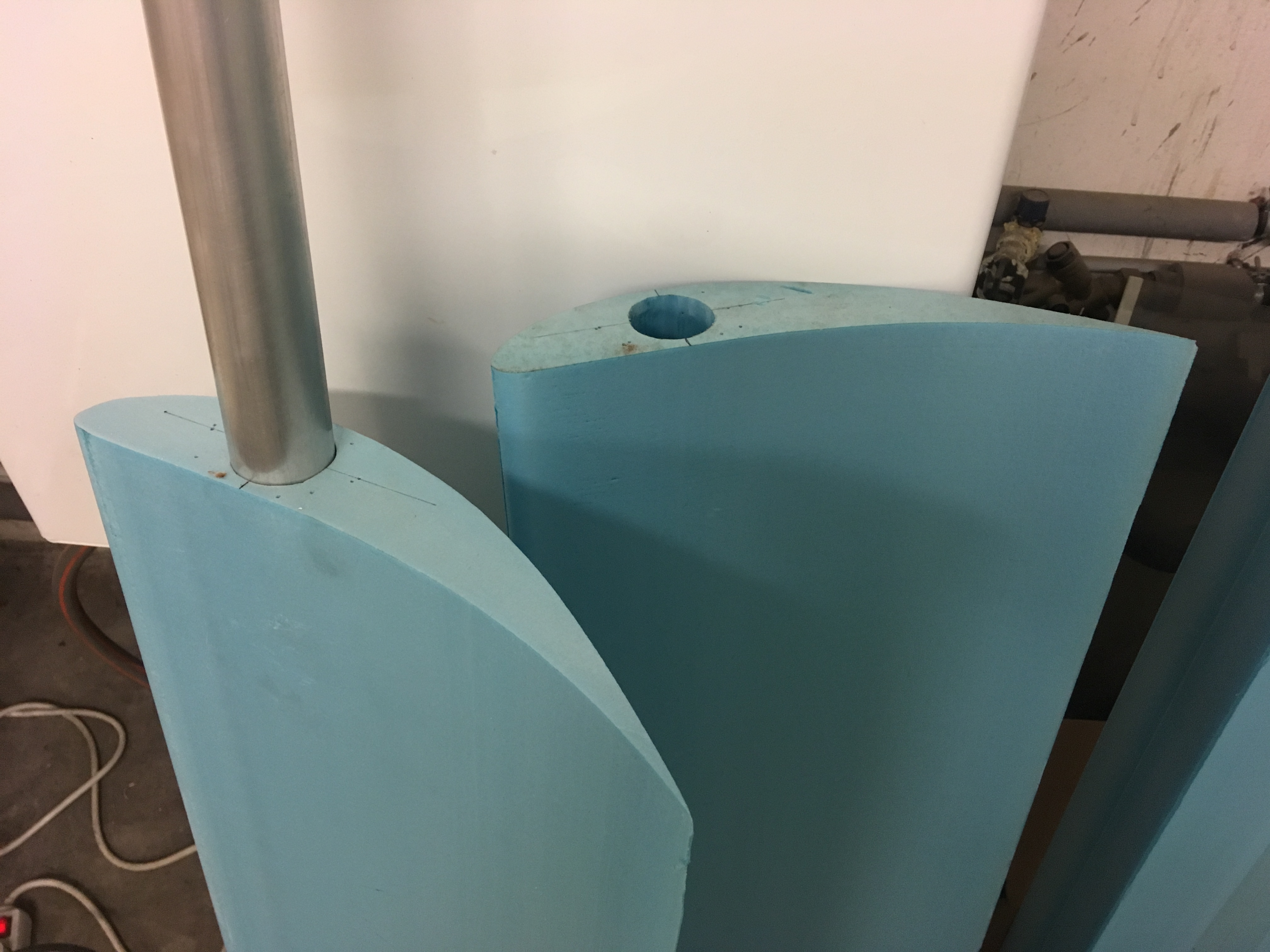

OUTER units:

- Indicator (center), yellow/amber filter

- Both ring segments regular lights

- Outward half-ring segment also brake (P21/5W bulb)

INNER units:

- Reversing lights (center), clear filter

- No lights on regular lights

- Inward half-ring segment for rear foglights

So basically the OEM setup only uses the outer units for all regular light uses and the brake lights.

The inner units are only used for reverse and rear foglights.

The back-story from Lotus at the time was that the original design was supposed to light all 4 rear lights for normal rear lights, but this ran afoul of type approval regulations at the time as the distance between the light units meant that the 'dead space' between them when added to the total surface area dropped the light output per cm2 below the threshold.

So by removing the inner units from the normal light function the imagrinary 'box' drawn around the remaining rear light unit has much less dead space and it passed.

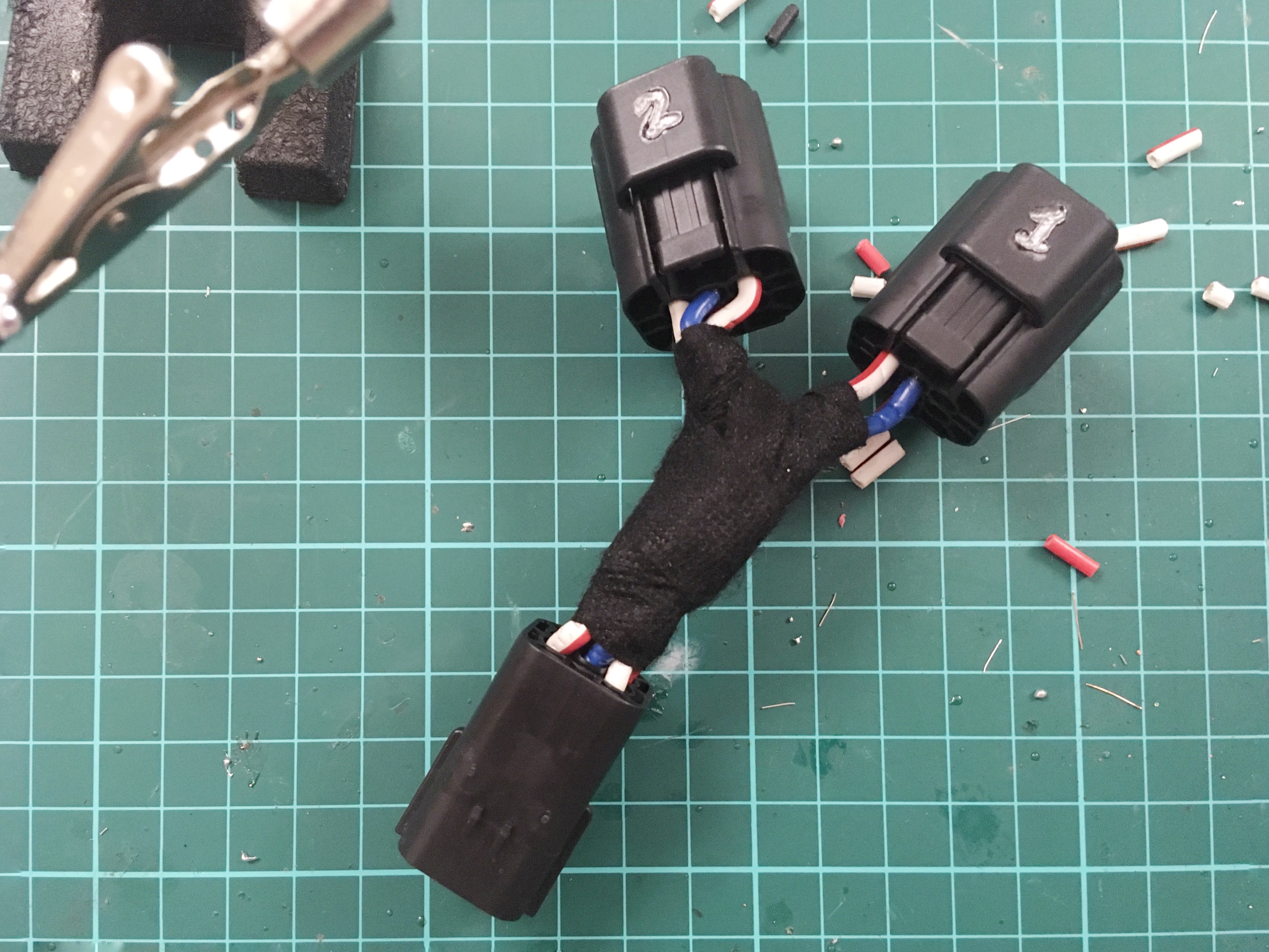

As a result, very early/demo/pre-production S2 units were 'open' on the back for all 4 light bulb holders and just had 2 holders with the wires cut as 'plugs' in them.

Also the very early/demo/pre-prod ones with this setup used P21/4W bulbs and different wiring compared to the later production cars with 'closed off' units and that use P21/5W bulbs. The reason for the 4W on one section of the inners is that the foglight half-ring sections are painted inside with a much more 'mirror like' finish and a 5W shines brighter in them. The regular light reflectors all have a more grey-ish reflector surface.

(and yes.. it's just silver and chrome paint inside on the reflectors  )

)

So it's common to 'mod' these by dremeling the opening back in the closed off (inner) units and getting your paws on some pigtails and bulb holders and get the orignal S2 design working.

Still doesn't change anything as far as brake/indicator/reverse/fog goes. It just lights up all full 'rings' for the normal rear lights too.

Your setup works fine too. Do whatever you like/want

Bye, Arno.