Top job sir, it's always good to see something different. I think there's a few envious people on here! :![]() :

:

Edited by rob999, 24 May 2016 - 06:02 PM.

Posted 24 May 2016 - 06:01 PM

Top job sir, it's always good to see something different. I think there's a few envious people on here! :![]() :

:

Edited by rob999, 24 May 2016 - 06:02 PM.

Posted 24 May 2016 - 06:16 PM

my ECU solution is "hand it to Dominik" (BadCop) ...who has developed his own custom software solution for the standard ECU, allowing integration of the CANBUS with the VX loom/instrumentation etc

uses the standard OEM looms of each. more details you can obviously get from Dominik himself, and also what product/computer packages he'll have available for purchasing

Posted 24 May 2016 - 06:29 PM

There's A LOT of smart people nowadays who drive speedster/VX 'es.The last few years , the evolution of this car is gone trough the roof! 5 or 6 years ago it was difficult to find people who could tune speedsters/vx 's in a proper way......

Posted 25 May 2016 - 03:12 AM

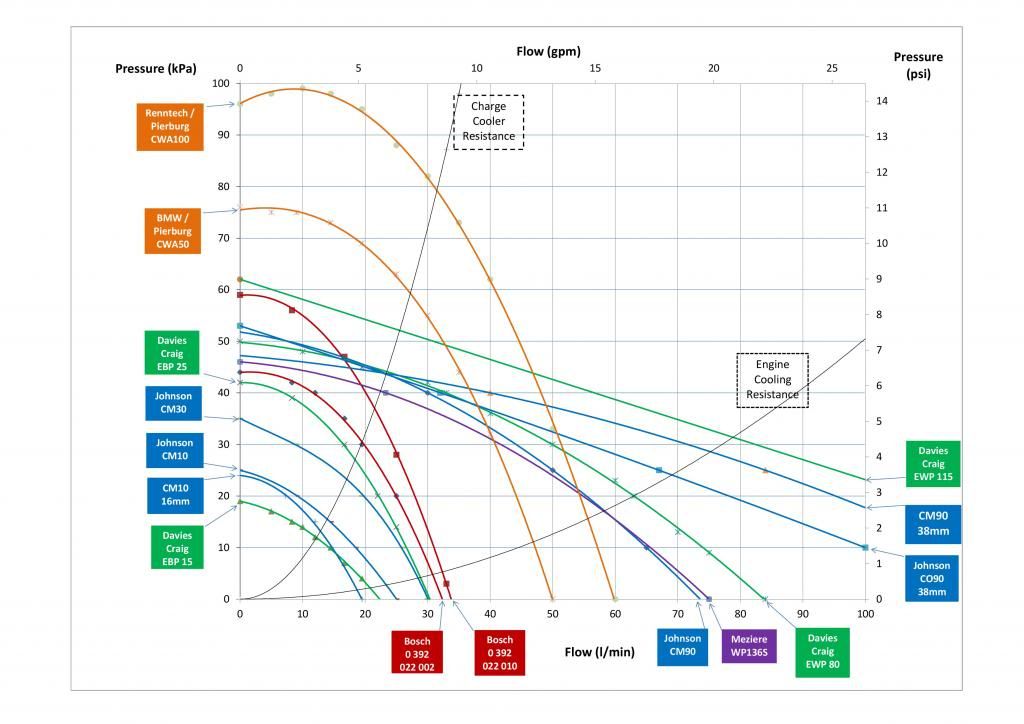

Yes of course it works. But the flow is a bit limited because - as you wrote this pump is designed for engine coolant radiation. So 35 -40 mm ID hoses, low resistance, low pressure ~0,3bar "boost" by the pump needed, very high flow like 1-2 Liters / sec. The IC circuit is much more restriktive, small ID, high pressure ~1bar. At that given pressure through that tiny diameters the pump will only do very little flow and run not very efficient. Anyway this setup is good enough to keep IAT under "ambient +10" on the track which is pretty good when you consider I run 27 PSI. Basicly the mission is to keep IAT under 55°C - thats where the ECM will start doing kr things. On the road I can't even get IAT higher than ambient +5... I'm pretty happy with the result but if I would do it again I'd choose something like a pierburg CWA50 and control it via PWM. @stu8v: No special wiring, just the OEM A20NFT Wiring harness. @Gedi: you can do everything as a home build and just purchase the standalone ECUany reason you think its not a good choice? seems the best high flow, low pressure pump I can find for reasonable money

Posted 25 May 2016 - 04:42 AM

Here is a picture of my W2A coolant pipework to the prerad

red = hot / blue = cold ![]()

You can see that I use almost the same inner diameter for IC hoses as the engine cooling to keep the resistance of the system low.

I've had the prerad custom made by PA for that diameter - think it was 30mm.

And this is how you bleed it - works pretty good ![]()

Posted 25 May 2016 - 08:43 AM

Be worth buying all European-supplied parts such as the ECU and engine before we leave the common market and the exchange costs sky rocket! ![]()

Posted 25 May 2016 - 11:57 AM

I guess this would be overkill for a chargecooling system.. http://www.ebay.at/i...=item51e44e2a85 Although similar spec to what Randy is using on his Europa race car..

Posted 25 May 2016 - 05:00 PM

have you actually measured 1bar pump head pressure? I could imagine the system having 0.2-0.4bar (4-6psi) head, but 1bar? seems like a lot.

if its truly 1bar, then yeah, I can see how the EWP115 would sh*t itself as a low pressure, high volume pump, but if less than 0.5bar, it pumps an enormous amount of volume, even if its a bit outside of its optimal range.

Posted 25 May 2016 - 06:17 PM

Posted 25 May 2016 - 06:18 PM

Posted 25 May 2016 - 06:23 PM

nope. an engine needs to be warm, not as cold as possible. a thermostat keeps the engine warm by restricting flow

an IC needs to be as cold as possible

highest flow possible results in highest heat transfer

Posted 25 May 2016 - 06:26 PM

Posted 25 May 2016 - 07:02 PM

the forum software isn't letting me link images... grrr...

(does anyone else find this site cause browser instability??)

but anyway... the CWA50 pump (on paper) doesn't appear to significantly outpump the EWP115

eg

CWA50 @ 0.5bar = 30L/min

EWP115 @ 0.5bar = 30L/min

they both seem to nose over at about 0.8bar

any real life experience to the contrary?

Posted 25 May 2016 - 07:16 PM

Posted 26 May 2016 - 04:36 PM

You wanted to add this one? ![]()

ahhh - CWA100 was the one I thought of ![]()

It was 0,8 or 0,9 bar before. I was using the 19mm heater hoses - which are even smaller in reality because there are some restrictions to I think 15mm in the way.

First I wanted to save weight by reusing those heater pipes/hoses - and not carry around to much water.

Anyway it didn't work. The flow was almost 0. If you turned IC pump on or not - the IAT raised the same -> no cooling.

Then I changed everything to the 30mm diameter - even the Prerad.

Now the head pressure dropped to around 0,3 bar.

As I wrote: now it works - I'm happy with my IAT. But it only works because the hoses are almost as big as the coolant hoses.

Not very efficent and +4kg Water.

If someone is setting up a new W2A IC system I'd go for the CWA50 or CWA100 which are designed to be charge cooler pumps.

Posted 26 May 2016 - 04:58 PM

the std heater hoses are about 14mm internal dia, so that would be a believable back pressure, particularly over the massive lengths they flow

Posted 23 July 2016 - 03:38 PM

After 10.000 km I just checked crank bearings, play in turbocharger bearing, wear on cams and many more things.

Everything perfect...

![]()

top speed with my new selfmade gearbox....

... 301 km/h (187 mph) GPS-meas.

Posted 23 July 2016 - 04:05 PM

You guys are probably aware already, but for others reading this, one of the best ways to lower IATs is to simply install a slightly "over"-speced turbo that is well within it's compressor map. Then you can then run it at low boost and IATs will be far less of a problem. Also, making sure your engine can actually flow/consume the charge easily helps reduce turbo effort (and hence IATs).

Posted 23 July 2016 - 04:28 PM

And highly efficent DI VVT Engines like A20NFT ![]()

Better volumetric efficency - lower load - lower IAT.

Highest IAT I have ever seen on the racetrack is 49°C ![]()

Even with the small K04 Turbo.

The big EFR Turbo would make about 550 bhp with that amount of boost.

(at a higher rev range of course)

Edited by BadCop, 23 July 2016 - 04:30 PM.

Posted 23 July 2016 - 04:45 PM

Telling this the VXT guys for the last few years or so... Running +1.5 bar boost for 290ish bhp is just/^$÷You guys are probably aware already, but for others reading this, one of the best ways to lower IATs is to simply install a slightly "over"-speced turbo that is well within it's compressor map. Then you can then run it at low boost and IATs will be far less of a problem. Also, making sure your engine can actually flow/consume the charge easily helps reduce turbo effort (and hence IATs).

0 members, 1 guests, 0 anonymous users