That's nothing to worry about! I wouldn't (and don't) worry about seeing 105 degrees whilst moving. When it's static the engine isn't under nearly as much load.I'm also seeing the same issue as you described. What I did eventually find out is that I still had some air in the rad slowing up the flow. It's worth running the car up to temp and loosening the rad bleed nipple and allowing lots to flow out as air periodically still vents out. Can take some time. Will watch this tread as still stays hot when on track and back in the pits on tickover stays at 105 unless revved.

The problem is that if you shut down at 105C after a track session without sufficient after shut down cooling is that the temps can go way to high causing a warped head or cracks.

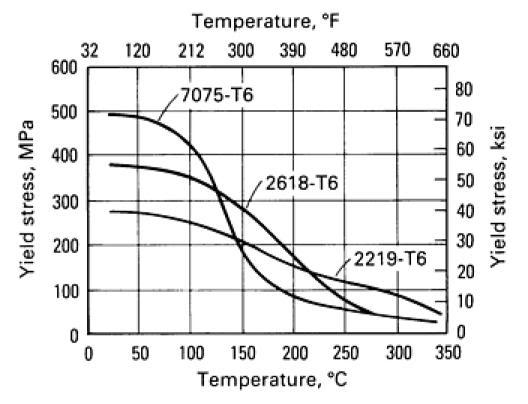

That is the bad thing with alu, it gets exponentially weaker with temperature. So running a engine cooler is better but you do get some increased friction that reduce efficiency...

And the temps shouldn't stay static at 105C if not under high load, then the cooling isn't sufficient.