[color=#1a1a1a;][font="arial;"]Hi guys, [/color][/font]

[color=#1a1a1a;][font="arial;"]Thought I’d start a project thread for my VXT stage 4 build I’m doing over the next couple of months. This is more for my benefit more than anything else, as I’d like to have a record of all the work done, nothing new that hasn't been done before. I've sourced the majority of the used parts from Alex who has been really helpful with answering all of my questions![/color][/font]

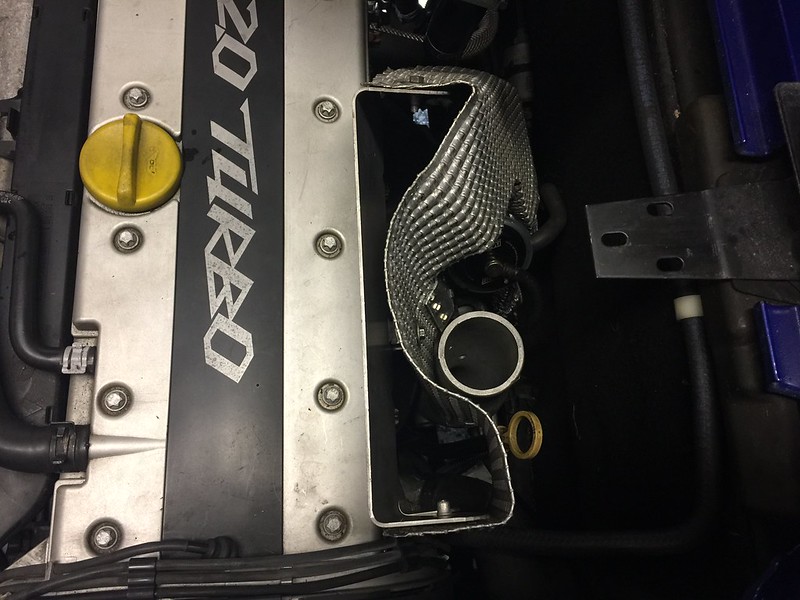

[color=#1a1a1a;][font="arial;"]Bit of history about the car, it's a 2003 coral blue turbo. My Dad bought it as cat C registered car back in 2005, we rebuilt the car together and I subsequently purchased it from him in 2011 (21st) It was a 1 owner car that had been tuned by Courtenay a few months prior to it being crashed! I guess this was in the really early days before the Pro Alloy CC kit was around as it had a "Pace" charge cooler fitted, although the cooler and pre-rad look good enough the hoses used were not up to the job at 10mm! I had the car on a RR a few years ago and it produced about 250BHP, must admit I was a bit surprised at the figure as it doesn't feel crazy quick like cars of a similar tune do. Seems to be reliable enough on the road but when you're pushing hard on track, Snetterton 300 especially you can see the IAT rise and the ECU backs everything off. [/color][/font]

[color=#1a1a1a;][font="arial;"]I've spent quite a bit of time getting the handling right so when the parts I wanted came up for grabs 2nd hand I decided to bite the bullet and upgrade the power and reliability to make what will hopefully be my perfect car! [/color][/font]

[color=#1a1a1a;][font="arial;"]Parts to be changed include:[/color][/font]

[color=#1a1a1a;][font="arial;"]Pro Alloy Charge Cooler[/color][/font]

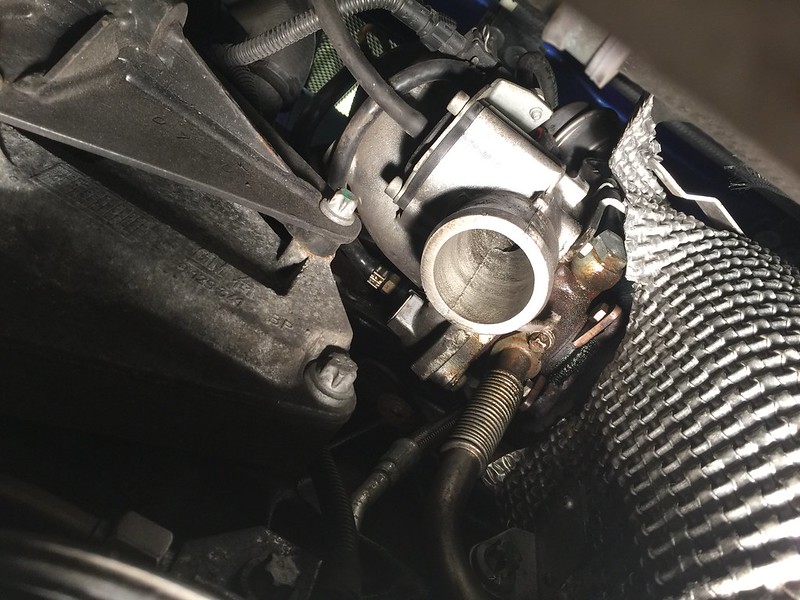

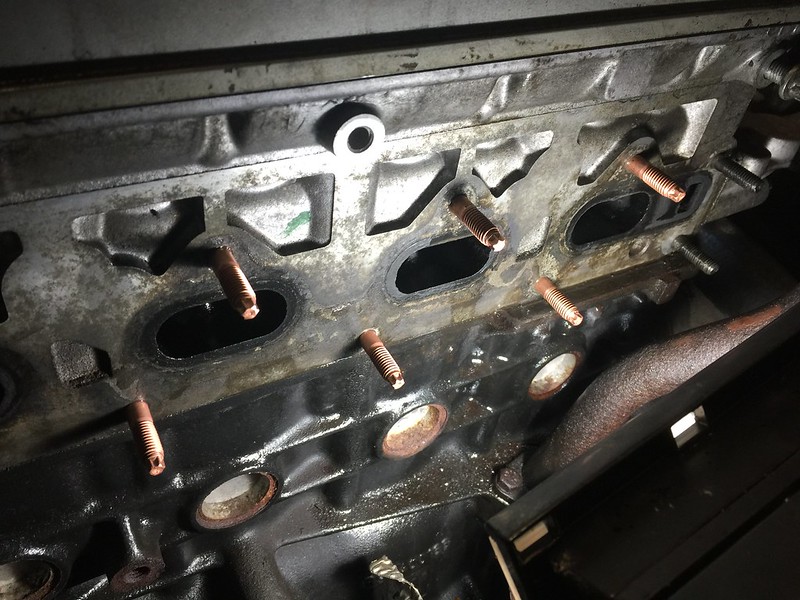

[color=#1a1a1a;][font="arial;"]K06 Turbo (new gaskets / studs etc.)[/color][/font]

[color=#1a1a1a;][font="arial;"]Turbosmart Actuator [/color][/font]

[color=#1a1a1a;][font="arial;"]Turbosmart Re-circ Valve[/color][/font]

[color=#1e1e1e;][font="helvetica;"]Deka 630cc injectors[/color][/font]

[color=#1a1a1a;][font="arial;"]80mm AFM[/color][/font]

[color=#1e1e1e;][font="helvetica;"]80mm intake pipe [/color][/font]

[color=#1e1e1e;][font="helvetica;"]Air filter (may modify the [/color][/font]air box)

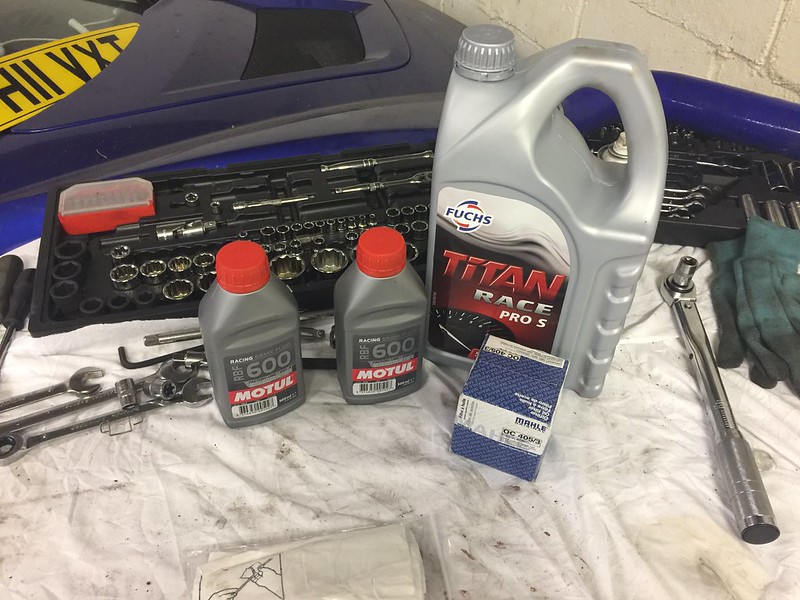

[color=#1e1e1e;][font="helvetica;"]Going to do the work myself over a few weekends, really enjoying it so far, it's nice to do a job without having to rush for once! I will replace / refurbish any worn bits along the way (though most things are up together now). [/color][/font]

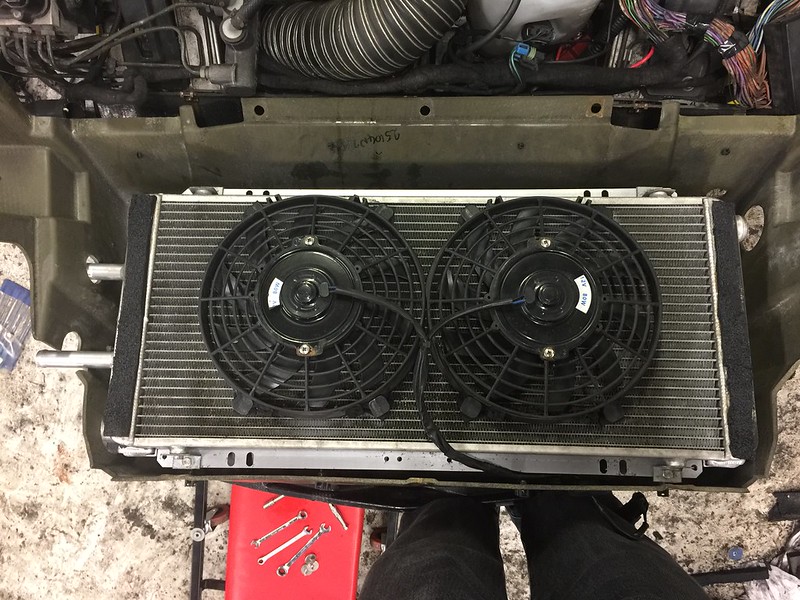

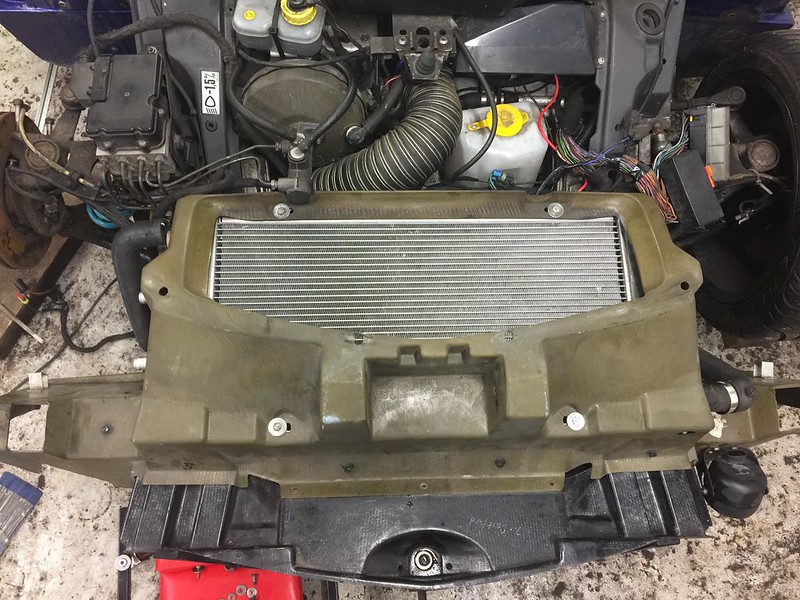

[color=#1a1a1a;][font="arial;"]Spent last Saturday taking the front clam off and removing the old Pace charge cooler system, the pre-rad sat directly in front of the grille with the hoses running through the cockpit via the centre console alongside the gear cables. The heat exchanger looks to be a bit smaller than the pro-alloy version and so was easy enough to remove without taking the rear clam off. Then there's the reservoir that I always thought was in a stupid place right next to the hot engine! I think the main issue with the kit is just the lack of volume. It's probably possible to weld some new connectors onto the hardware and run 19mm hoses throughout which would help but I'd rather do it properly! [/color][/font]

Not got the new parts yet but I'll probably get the rear clam off on Sunday just to make access easier! No doubt i'll be asking lots of silly questions along the way, but I really can't wait for it to be done! ![]()