Hi all,

This has been a long time coming, but this is the first update on the build progress for Project VX220. Mainly it's been a case of stripping the car down to its chassis to inspect everything and ensure there's no major unsighted damage!

Firstly, the two prototype cars we have are now completely stripped for all parts. This means we have a healthy supply of spares in the event of accident or failure from what was otherwise two useless vehicles (one of them was "rocket powered" and the other had partly been converted to electric, but never finished..). If any of you need any spares (including reasonable wishbones, clams etc) let me know!

Secondly, the main car we're using has had the engine lifted and stripped, all suspension taken off and interior removed. It is very much a bare chassis! I'm happy to report that all seems to be well with the chassis and there's no structural damage (as an ex ARDS test car, it hasn't had a happy life!). The engine was not so happy, and I'm amazed it was still running. Not only had the drive belt stripped in half lengthways, it also had a twist in it - moreover the tensioner on the cambelt was seized solid!!

The engine has been stripped on the bench, and as the tappets were removed a couple of them exploded - I imagine this is due to the fact that the engine has sat unmoved for 8 years or so - if the valve was "open" there would be a lot of force resting on the hydraulic tappet. We're not planning a huge amount of interior engine work - we're currently talking to ARP about a sponsorship deal so would be replacing the main studs, rod bolts and head bolts with ARP fasteners which will give us all piece of mind! The bores look great - you can still see the factory hone marks so I'm pleased with that; I was worried that despite its low 21,000 miles on the clock, as a driver training car it may have spent hours in the pitlane on tickover. We've got two brand new C22LES engines that have been in the shed for years (I have no idea why), so several parts can be robbed off those including the cylinder head, plus we're going to test fit the N/A cam which has 1mm of extra lift and seemingly no extra overlap. If it fits without touching the piston it's a cheap way of getting more power! We're also removing the balance shaft and, as per Nev's suggestions, fitting high tensile bolts in the ladder.

Hopefully, if the guy on the team can do it in time, we'll have a lovely three inch tubular exhaust manifold to replace the abomination that is the OEM one (plus a three inch exhaust post turbo). This will mate to a K04 RS turbo which will happily get us to the desired 280odd bhp (at the fly). To make sure the fuelling doesn't suffer, larger Bosch injectors are being fitted and a LIFE Racing ECU is also being installed (the F88 with all bells and whistles.)

The next issue is fuel capacity - as I'm sure you all know the VX tank is 38 litres, which isn't exactly suitable for 3 hour races... Pro-Alloy and the likes make a 60 litre tank but this still isn't enough! We've got data from a KTM X-Bow GT4 car which has a similar weight and power to us, and this uses roughly a litre of fuel a minute. Regulations also say that if there is a red flag on the first two laps of a race, the race is restarted without cars going back to the pits. If you consider a two hour race at Spa, and the two warm up laps use say, 3-4 litres of fuel. Lights out and on the chicane before the start/finish on lap two there is an almighty shunt and a red flag. That's another 4 litres of fuel used so the car, which started on 60 litres, is now down to 52. The next warm up lap (we are on rolling starts) uses another litre or so, so that's 51. After 50 minutes the car is boxed for refuelling with one litre in the tank (ignore surge for this example), with one hour and ten left to go. We, by regulation, cannot fill by more than 50 litres, hence unable to finish the race without another stop! For that reason, we're installing an 80 litre tank, and to do this we'll be removing the bulkhead that separates the driver from the tank, fitting a new tank, designed and built in house that encroaches on the passenger space, and manufacturing a new bulkhead/firewall. Twin low pressure pumps will feed a swirl pot, which will feed two high pressure pumps (one on, one failsafe).

Braking - I've heard that the brakes on the VX are poor for extended (race) use, and seeing the size of the pads I'm inclined to believe it! We'll be fitting larger, Alfa Romeo 159 brake discs that are 308mm in size, with the stopping power provided by a pair of Wilwood 6 pots. I was against 6 pots initially as I felt it was far, far too much for the car, but the Forged Dynapro callipers are relatively small and the piston surface area is similar to that of a Brembo 4 pot, but with better heat dissipation. Coupled with large master cylinders so the wheels don't lock up due to a sneeze and you have a relatively low stressed system! On the rear, we will fit the OEM front brakes (AP 2 pots), and the balance between the brakes will be controlled through a Wilwood bias controller fitted to our custom in house pedal box.

Suspension - I've completed some roll centre analysis and noted that just by lowering the car by 50mm or so destroys the position of the roll centres, which will cause the car to roll like a boat! For this reason we're designing and producing our own uprights from 7075 grade aluminium. These will use a spacer/packer system to adjust the roll centres depending on ride height, so you can run at different ride heights will similar roll characteristics. Seeing as we're running at both Rockingham and Spa, this will be an excellent way of maintaining the handling behaviour at two very different circuits, and allow us to fine tune the roll. Nitron coilovers are intending to be fitted - four way adjustables if we can get the budget, one way if not. Spring rates will be set once we get the aero loading from the CFD. Finally, all the bushes are being replaced for spherical bearings to completely eliminate compliance!

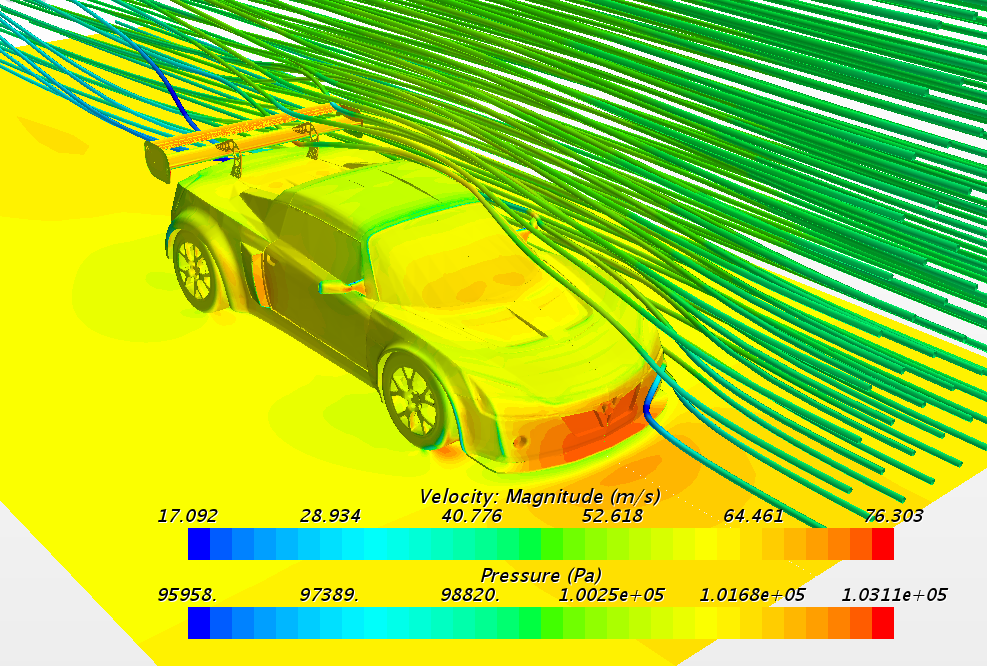

Aero - A full aero package is in the works, including a splitter, a diffuser that doubles up as a tank guard and a rear wing. The splitter is relatively straight-forward - a flat design that in theory must be strong enough to stand on. Easiest way to do this is with 15-20mm marine ply! The diffuser will have a reinforcing plate to guard the tank from curb damage and knocks, then a straight line upwards to the clam. The aero guys have played with compound curves and straight designs and found that for both the diffuser shape and the strakes/flow separators that straight lines are better, interestingly enough (higher L/D ratio).

The rear wing is going to be of two element design and initial analysis have shown it capable of nearly half a ton of downforce!! Obviously it is highly unlikely you'll ever run with this - it needs to be representative of what the front can produce - total car downforce is estimated to be roughly 350kg at 100mph. The wing also has a lift/drag ration of over 12:1, which is excellent! Louvres in the wheel arches will reduce wheel well pressure and increase downforce (by reducing lift), and the fog light housings will be used to feed the front brakes with cold air. Finally, we'll be making our own wide arch kits as we're increasing the track width with larger wheels and tyres.

Wheels and tyres - to house the larger front brakes and to widen the tyre choice as well as allowing the car to be capable to take the extra power and aero load, we're fitting 225/45/R17s to the front and 255/40R17s to the rear, mounted to Revolution wheels. Tyre choice is currently undecided but has to be an MSA 1a/b/c tyre, so will be a semi slick like the Yoko A052, Toyo R888r, Nankang AR1, Pirelli Trofeo R or MRF, depending on what deal we can get!

Extra - The Safety Devices Cage has been test fitted and Schroth are supplying us with an amazing set of "endurance spec" seat belts, which is great. The wiring loom is being completely replaced and we're hoping to get Cartek onboard with a Power Distribution Panel. We're also hoping to get a seat from Corbeau, and will be fitting a Momo steering wheel on a B-G Racing quick release boss to aid getting in and out of the car.

Sponsors - Without the help of the companies below, this project would be absolutely dead in the water. We're always looking for more sponsors and have several currently under negotiation, but here is what we've got so far.

Draper Tools - Draper have supplied us with a range of Draper Expert tools, and without them we'd be very stuck! The quality of tool is excellent and surpasses that of the more prestigious brands. The open ended ratchet spanners, once you get your head around them, are a favourite in the team and the alloy racing jack is one of the best I've used. Chris Bartlett is the man to speak to.

FEV - The Fire Extinguisher Valve Company have kindly agreed to supply us with a fire extinguisher for the car. This is an electric extinguisher that is loaded at 9 bar and meets the brand new FIA regulations. Their kit is excellent quality and Anna at FEV is extremely friendly!

Physical Digital - Physical Digital are THE people to go and see for any reverse engineering or 3d scanning requirements. They've scanned our inlet manifold, exhaust manifold and suspension uprights for us and this allows us to model and test the components properly. They do all sorts of work, from motorsport to military, from tiny components to aeroplanes, with an accuracy of just 5 microns!! Contact Lucy if you need anything done.

Fix Auto - Fix have agreed to paint the beast for us when completed which is massively appreciated (we're going purple!). We'll no doubt put some photos up when this is completed (sometime in May)

AA Oil - Anglo American Oil are our supplier of oils, coolants and brake fluid. Anders from AA Oil has educated the team as to the benefits of a new brand they're stocking, DRIVEN racing oil, over some of the traditional brands. The benefits are too many to mention here, so I'll do a bit of a write up at a later date.

Wilwood - very friendly and knowledgeable, Wilwood have offered us a great university discount on their products. East to deal with, Kaleb from Wilwood has had quite an influence on speccing the brakes on the car!

Vauxhall - Obviously, thanks should be given to Vauxhall for giving us the cars!

Think Automotive - The guys behind Mocal Oil Coolers and Setrab, Think are helping us with all the plumbing fittings on the car. They're also extremely knowledgeable on all aspects on prepping a racing car, and I spent well over an hour chatting to them at Autosport! Matt is the main man, but they're all great to deal with.

Schroth - As mentioned, Schroth are kindly supplying us with a set of harnesses and can easily be considered to be one of the best harness makers in the business, from aerospace to motorsport.

Mount Batten Boathouse - Marine engineering experts and one of the best in the South West of England, these guys are helping us with technical advice for composites and supplying us with the consumables required. Speak to Gavin or Bill if you need anything (for a boat or car!)

B-G Racing - Top suppliers of pit equipment, I use their stuff with my own race car (I race an Alfa 156) so was very happy when they said they'd support us with this too. Also the UK dealers for Momo.

There are quite a few more we're currently talking to, but I'll update as and when! We're always looking for more sponsors so let me know if anyone is interested in helping us!

Thanks for reading this long post! If you've got any questions or suggestions go right ahead - you are all more familiar with these that we are so we're bound to miss something!! First race is 10th of June in Rockingham which is a 3 hour race, then 6/7 July at Spa!

Finally, we have a spare VX220 that we would like to get rid of in return for some more development budget - it is not in a great state (no windscreen, a bit "green") but does run. I will add photos of it in the for sale page next week, but we're looking for 4-4.5k for it. It's not road legal or even registered, but would make an excellent track toy with a little work! (it's a vx220 turbo).

Cheers!!

Alex.

UH