I have been asked to expand on how I produced the crash box intake walls and internal diffuser using the PVC plastic sheet and show how I actually formed the shapes. As I have already made the crash box diffuser/ walls, I have documented how I produced the bonnet air exit cowl that will eventually be produced in carbon fibre. The procedure was the same.

Clearly, there are numerous ways to cook an omelette. There may be a quicker alternative, which I have yet to uncover? Anyway, this is how I produce the sculptured cowl.

Materials used:

1.5mm PVC plastic sheet

Scrim tape

End stop plaster beads

Tools used:

Multi-speed Dremel

Paper and masking tape to make templates

Stanley knife

Hot air gun

150mm metal pipe

Permanent marker pen

Sandpaper

Soft Black rubber spreader

Step 1:

I used plaster end beads cut and fitted to form the basic shape see below. Make sure the plaster beads are fitted and rigid. I've screwed the beads to the OEM radiator cowl and to the bonnet. You can use a hot glue gun or similar adhesive. You need the beads to be fixed well for when you make the templates later.

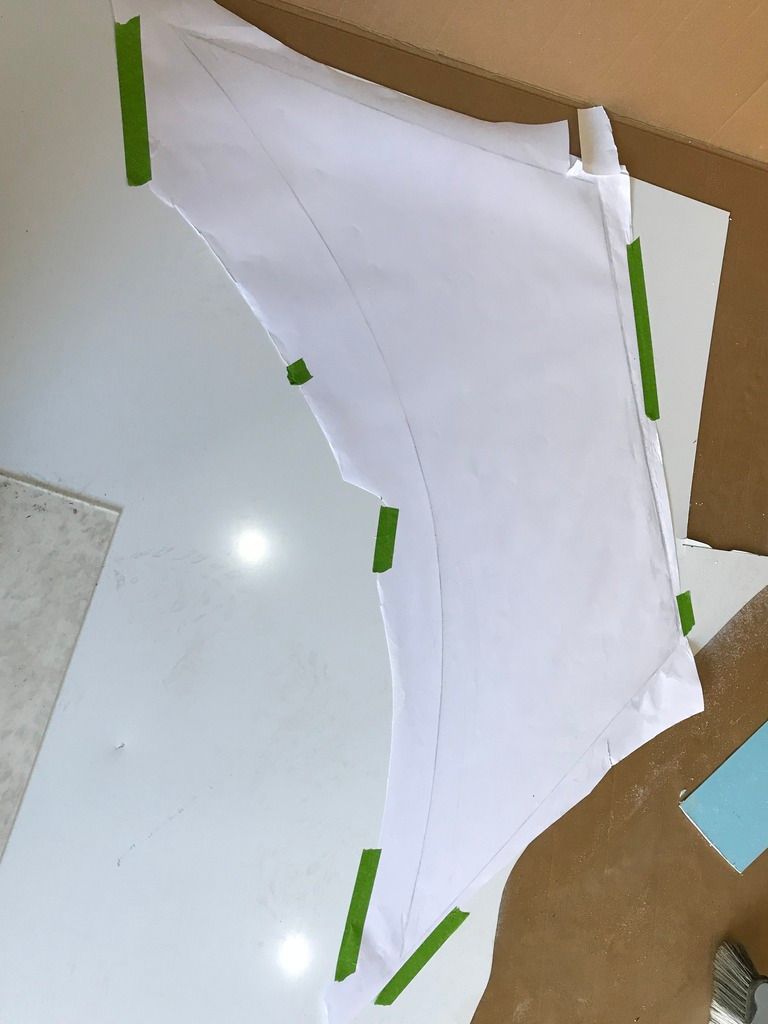

Step 2:

Make the back curved surface by cutting a piece of paper and taping it over the plaster beads. Then using the soft black rubber spreader, rub through the paper against the bead edges. This will leave an accurate line where the bead edges are, hence why the beads need to be well fitted.

Step 3:

Stick the paper onto the PVC sheet and tape done with masking tape, don't try and cut it out with scissors, it won't be accurate enough.

Now using a Stanley knife cut through the paper with enough force to just cut into the PVC sheet. You will now have a faint accurate line on the PVC sheet. Using the sharpie permanent marker pen draw over the faint scored outline. The pen will follow the groove without deviating.

Step 4:

Using the Dremel with 16mm diamond disc on low speed, cut out to the outside edge of the black line. Lightly sand the edge as this will fit into the bead edge.

Step 5:

Fit in the cut PVC panel into the plaster bead outline. The panel should fit perfectly into the groove on the bead and stay in place.

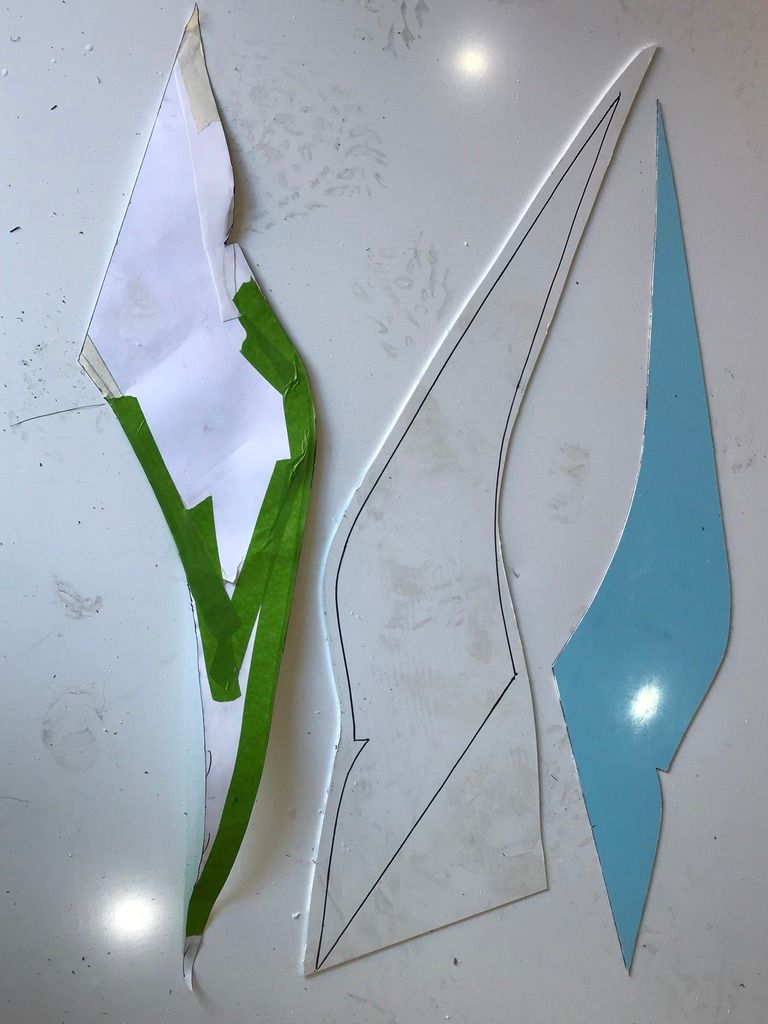

Step 6 (Curved side panels):

Using paper, cut an approx shape of what you think the curved sides should look like. Keep adding pieces of paper or cutting away areas until you have a close approximation of the panel you want to make. Now use narrow masking tape to build up the edges so that your paper stuck together pieces becomes far more accurate.

Step 7:

Stick the made-up template onto the PVC sheet and trace around with the marker pen and cut out with the Dremel as before

Step 8:

Gently heat up the cut-out shape over any object or form that has similar contours to what you want to achieve. I used a section of log burner flue and also an old silencer. You can smooth out the shape with your hands, obviously wear gloves! Have a hand sprayer with cold water in to spray the plastic to harden the shape. Gently heating the plastic over a pipe or silencer will make the plastic take the shape of the pipe or silencer, without any additional manipulation. If you get wrinkles, just gently heat again and they will relax and disappear. You will obviously need to trial fit often to see if your changes are getting better or worse!

You can heat and cool as many times as you like. I also used the side of my lawn mower, which had curves on the bodywork. It may take a little practice, but it gets easier with each attempt.

Step 9:

Sand any minor imperfections out with 80 grit, then finer paper to remove any scratches.

Step 10:

Fit into place with scrim tape or mastic, hot glue gun or using plaster beads. (See photo below)

Step 11:

Fill and sand to achieve a perfect surface. Then use as a mould or wet lay CF over. Remove when hardened and improve.

The radiator exit cowl does fit perfectly, but due to the flex in the sides, I will have to seal it properly in position.

Do you think I should make the radiator air cowl part of the bonnet or as a separate panel? The front bumper will be a separate section.

Anyway, I hope this was useful. I must say, the PVC plastic is very forgiving and easy to use. I may also do an enclosed air filter housing using the PVC to form a cowl, then wet lay CF over.