Firstly Lotus changed the rear bolt spec to 10.9

Information from the 111 S2 using steel uprights

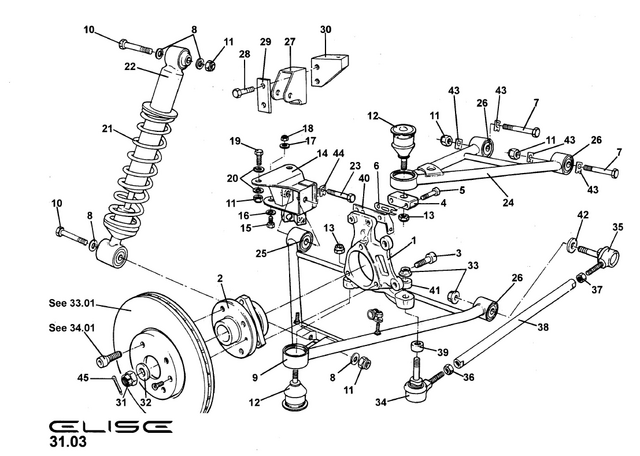

The original A111W7145F M10x50 bolt rear hub carrier is grade 8.8 and the service manual states torque 45Nm or 33lbft (NOTE some S2 parts manuals list Rear suspension part #5 as A111W1745F which is probably a misprint)

In 2004 Lotus issued service bulletin 2004/08 which revised the part number to A117W7212F with a new 10.9 grade specification to be torqued to 68Nm or 50lbft for motorsport use.

The front bolts A111W7155F and A1117W144F are not affected and remain 8.8 grade and 33lbft torque.

Second the Lotus service states that all the nut torques should be checked, do you think vaux do this???

Just some more useful ( essential ) information, since owners will be disturbing bolts, plus there are a few on here that are in the midst of a complete strip down.

Note where changing from 8.8 to 10.9 a higher torque should be applied when tightening / checking

The Service Schedule specifies that the security of the front and rear suspension is checked at each service. This operation requires that all the principal suspension pivot bolts are torque checked, noting the following points:

Where a bolt is tapped into a housing or weldnut, and relies on a thread locking compound for security, it is important to appreciate that if the bolt is disturbed, the locking compound must be re-applied. The following procedure should be adopted for all such fixings:

- Check the torque of the fixing.

- If the specified torque is attained without the fixing being disturbed (moving), take no further action.

- If the bolt moves, the locking action of the thread adhesive will have been lost. Remove the bolt completely, clean off all old adhesive using a wire brush and acetone, and apply new adhesive as specified.

- Refit the bolt and tighten to the specified torque.

- If for any reason a bolt is found to have become loose, and the car has been operated for any period in this condition, the bolt should be renewed as a standard precaution and related components carefully inspected for hole ovality or wear.

Torque Settings: Nm

- Upper and lower wishbone pivot bolts 45

- Upper swivel joint to steering arm 55

- Lower swivel joint to plinth 55

** - Lower swivel joint plinth to hub carrier 45 **

- Steering arm to hub carrier 45

- Track rod end to steering arm 30

- Damper to lower wishbone 45

- Damper to chassis 45

- Brake caliper to hub carrier 45

- Anti-roll bar rubber bush mounting clamps 20

- Anti-roll bar drop links 45