Yep, the standard roof cleaning kit

I've also tried the Meguiars kit - the cleaner is a bit better than the Autoglym one, but the waterproofer is nowhere near as good

right i might try them both and get the best of both worlds, cheers

Posted 23 August 2009 - 05:06 PM

Yep, the standard roof cleaning kit

I've also tried the Meguiars kit - the cleaner is a bit better than the Autoglym one, but the waterproofer is nowhere near as good

Posted 23 August 2009 - 10:31 PM

Posted 27 August 2009 - 09:50 AM

Posted 27 August 2009 - 09:53 AM

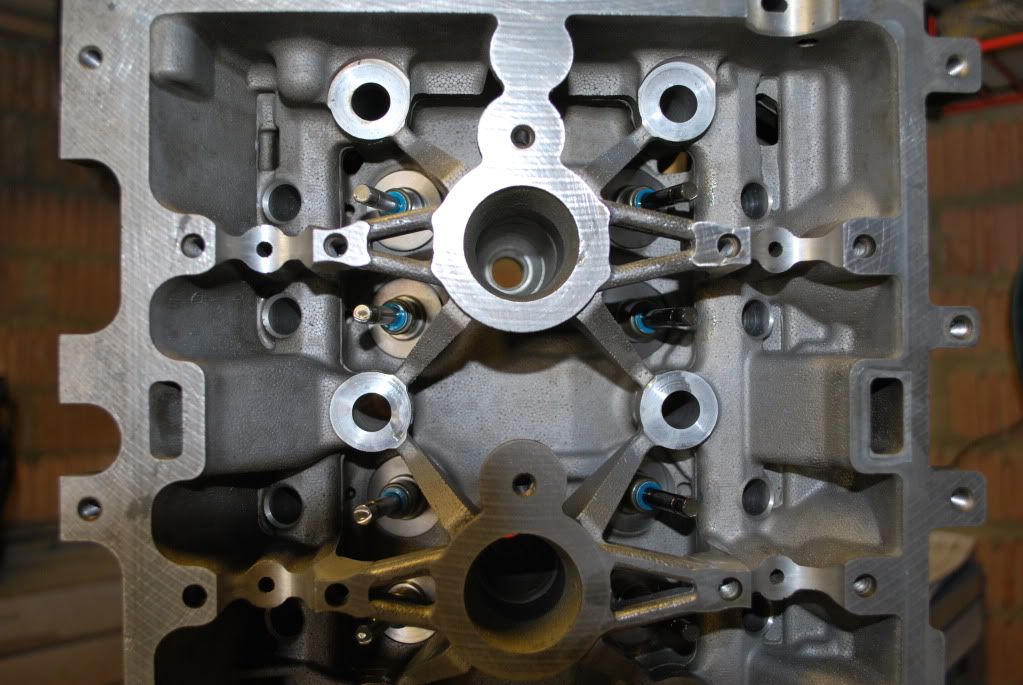

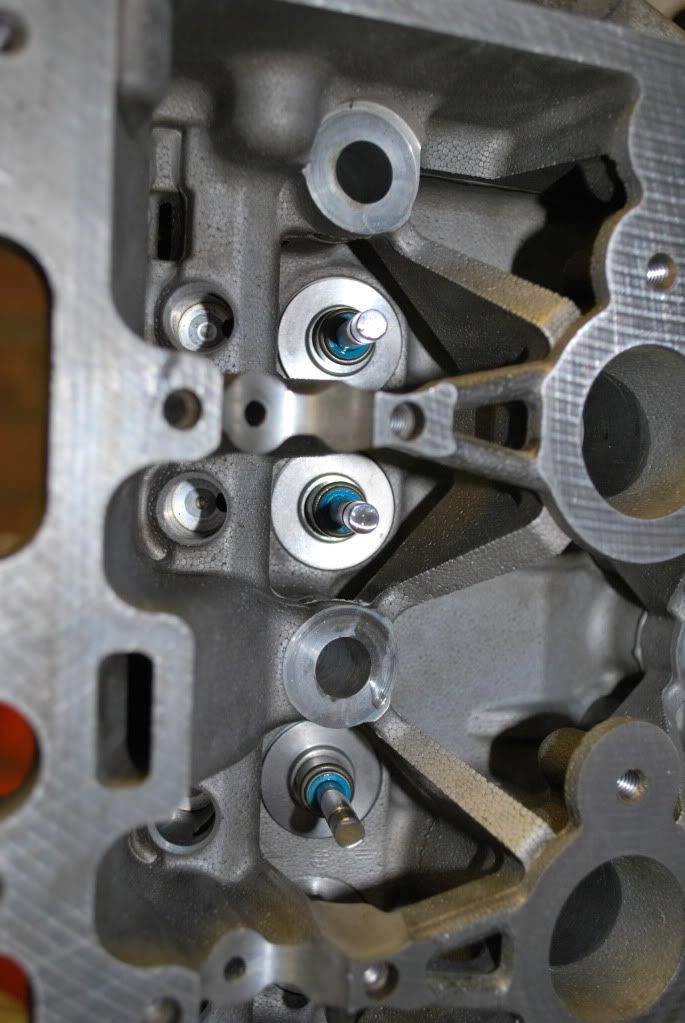

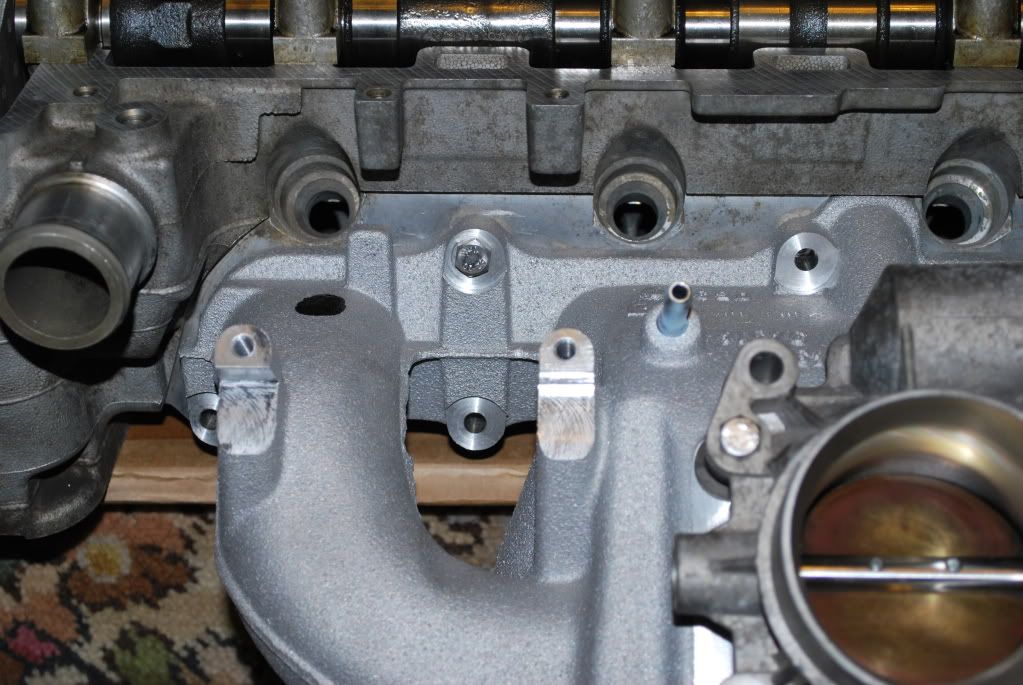

Looking at the close up picture of the valves, it looks like the head is made of polystyrene!!!

Posted 27 August 2009 - 03:13 PM

Posted 27 August 2009 - 03:30 PM

Posted 27 August 2009 - 04:16 PM

Posted 27 August 2009 - 09:13 PM

rubbish, the engine is polystyrene just sprayed with some hammerite silver paint

Posted 28 August 2009 - 09:08 PM

Posted 28 August 2009 - 09:32 PM

Posted 28 August 2009 - 09:44 PM

Posted 28 August 2009 - 10:20 PM

Posted 28 August 2009 - 10:23 PM

Posted 28 August 2009 - 10:36 PM

Posted 29 August 2009 - 06:55 PM

Posted 29 August 2009 - 07:02 PM

Posted 30 August 2009 - 02:34 AM

Posted 30 August 2009 - 10:14 AM

Posted 30 August 2009 - 10:37 PM

0 members, 2 guests, 0 anonymous users