Right then - The Rotrex plan

The Charger

The Charger

A Rotrex 30 series either the 84 or 94 - not sure yet

The 84 has a range of 200-320bhp and the 94 from 250-400bhp; although I'm not sure how those figures are derived I'd have thought there a too many variables across engine types to give an actual power range

It will be mounted where the air con compressor would sit on a Veccy, just below the alternater

The Engine

Nice and simple:

change rods to Eagle H-beam

Fit two (or three) Saab head gaskets, with rivets drilled out; to drop compression a little - need to do a couple of calcs first I guess

I already have the ported head with double valve springs etc and GMP valves so that will be fitted - probably stick with OEM cams for the time being and fit Comp Blower of Saab turbo cams if needed

The Exhaust

I already have a full Piper 2.5" system with manifold; should be good enough for the 250-300bhp I'd like

May get a wideband gauge

ECU

ECU

Three options really:

Find someone that has truly 'cracked' the OEM ECU, nice and neat but not sure how realistic

Fit 'piggyback' fuel controller - I've found someone with good experience of the AEM version

Fit aftermarket solution - would rather avoid this route as it will mean aftermarket 'kit' type solution prices will start to soar

Cooling

The centifugal blower is far more efficient than the roots type, making cooling a bit of a black hole

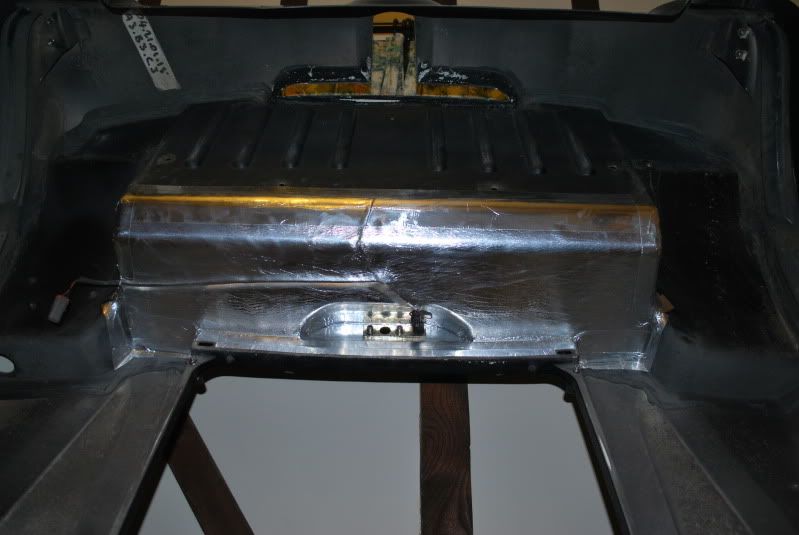

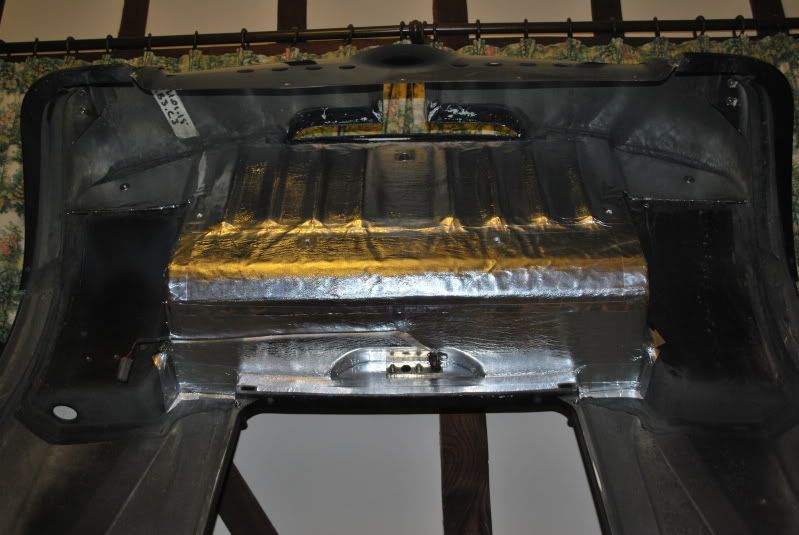

I have a VXT intercooler to try, but will need to find some way of mounting it - if it works then I'll ask ProAlloy or similar to make up a neater/lighter/more efficient permanent solution. The tubby position is ideal as the piping would exit the charger into a 90 degree bend, then under the chassis beam and into the intercooler, then out the top of the intercooler and across into the TB

If I require more cooling then may have a play with a water injection kit

And if even more is required then a full-on chargecooler (but I don't anticipate it needing that much)

I'm going to fit the tubby side vents too

The layout of the engine bay suggests that latent heat gains wont be as great an issue as they are on a tubby

Air Intake

Air Intake

Ideally mounted directly into the charger, but there may not be space in which case I'll have to mount it in the more usual position, but ideally I'd like to keep all pipe runs as short as poss

I plan to use the OEM plastic 2.2 manifold for now - if that doesn't work I'll need to use the Saab cast manifold (already got one just in case

)

Main thing I'm not sure on is injectors

Any suggestions welcome