PS2; never though much about the KPI influence on camber gain, but I see now that it reduces the negative camber gain on steering... ![]()

Somethiing I found on the Locost site and quotes Milliken race car dynamics:

"with no KPI (and no caster) there is no camber change with steering lock. As KPI is increased (but still no caster) the wheel will "lose" camber with steer lock, or in other words it will change in a direction giving positive camber on the outside wheel. As caster is added, this modifies the affect of KPI. With positive caster and no KPI, the wheel gains negative camber on the outside wheel and positive camber on the inside wheel. Thus caster can add favorable camber angle to the affect of KPI. In other words, the reason that low KPI is desirable is that KPI subtracts from the negative camber gain due to caster on the outside wheel."

"If you consider a design with 10deg KPI and 10deg caster, when the wheel is turned through 90 degrees you'd have the sum of:

10deg positive camber as a result of the KPI

10deg negative camber as a result of the caster

The net camber would be zero. Of course we'd never apply 90 degrees lock, I've read that the maximum steering angle see on a track is around 8 - 9 degrees. At 9 degrees you'd get about 10% of the camber change produced by the combination of KPI and caster.

So if we had 0 KPI and 10 deg caster, and applied 9deg of lock (instead of 90) we'd see about 1 degree negative camber."

Interesting stuff...

Big Power Vxt Project

#4541

Posted 19 March 2019 - 03:17 PM

#4542

Posted 21 March 2019 - 12:37 PM

After a series of extended tests (which involved changing 7° wishbones to 5° in Southern Spain) I settled on 5°KPI and 3° caster. At this I found for me the ideal front to rear grip delta.

Hub carriers I machined back 15mm and the steering arms back 5mm to allow the 20mm longer upper wishbones. Besides length upper wishbones were also altered by moving the upper pivot forward slightly to reduce caster about 0.5°. Lower wishbone remains standard as do the height of pickup points.

Roll centre is largely unaffected as wishbone anges remain almost the same.

A side effect of reducing KPI is the increase in scrub radius as recognised by Exmanta. My second aim after getting rid of positive camber on turn in was to reduce steering loading in corners.

More positive scrub radius means the static tyre contact point moves further in front of the steering pivot axis on turn in so the lateral forces during cornering help steer the loaded wheel into the corner reducing turn in resistance created by the caster. From memory my mods increased scrub radius by 15mm.

Rear suspension on the car is also slightly unusual. It rides 112mm rear and suffered bad bump induced rear camber changes. Once the VX/Elise rear suspension is lowered the rear upper wishbone goes well out of horizontal so vertical movements of the wheel mean the top pivot moves in and out much more than designed, causing extreme camber changes. The lower wishbone is long and more horizontal so track on the lower pivot barely changes with bump. I looked at the bump/camber curve at its standard ride height (140mm) and decided this was needed at my preferred lowered ride height. A series of calculations revealed the standard rear bump/camber curve could be regained at 112mm ride height by lowering the rear upper wishbone pivot point by 18mm. The rear end is now very behaved and since this mod has been untouched for 35k miles. An added advantage is the upper wishbone is now well clear of the subframe. Only downside is approx 10% increase loading on the upper wishbone.

Of course the very same can be achieved by fitting GT hub carriers.

#4543

Posted 21 March 2019 - 01:12 PM

is the ackermann geometry okay?

#4544

Posted 21 March 2019 - 11:51 PM

Thxs for the technical clarifications. 20mm is a lot and that is quite some machining from the hubs. But very interesting and you seem to like it on track. ![]()

I drive with 30mm offset hubs on the front, but still original ones in te rear. Not too low because of the geometry but you can see the wheel camber changing when you drive behind a VX/Speedster. So I also did look into lowering the rear top wishbone like you have done, but seemed not very easy to do. Did you weld-up the steel hub to make space for the lowered threads.. ![]()

#4545

Posted 22 March 2019 - 09:53 AM

Get that Nipper ready Nev. This year will be my 6th road trip in the VX to Andalusia, it gets better each time.

are you driving down via France , or taking Ferry?

Yes drive through France. Empty back roads across Normandy then twisting down the spine of the Massif Central. A brilliant drive. Head south and head east along the Pyrenees, south again down the Ebro valley. Next it’s free running across the isolated mountains of inland Spain - Aragon, Valencia, Sierra Nevada, Rhonda. First time I did this in 1999 with a very rough around the edges 1968 911S. Had to stop and adjust all six carburettor chokes each time we drove a significant altitude change :-). Great times.

#4546

Posted 23 March 2019 - 10:32 AM

is the ackermann geometry okay?

Good point but I hope there would be little change. The steering arms are still within normal adjustment range at castor 3°. There is no change in effective length of arm. They are 20mm further outboard so the track rods are longer but I don’t think this would have much effect. Might reduce bump steer a little. Tyres are wearing dead flat and it feels great. I will get the Ackermann floor gauges out and check.

#4547

Posted 23 March 2019 - 12:45 PM

How did you lower the rear hub top side mount? Welded up the steel hubs for the 18mm lower threads?

#4548

Posted 23 March 2019 - 01:05 PM

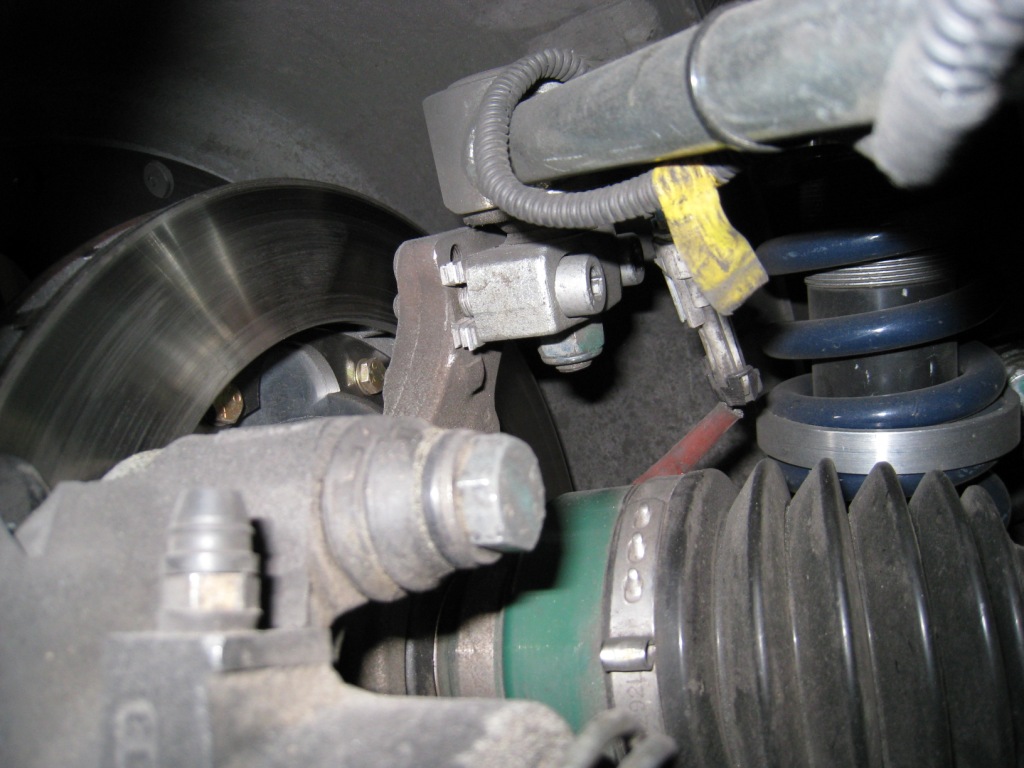

This is a lowered rear top mount that I once got info from a US track Elise (2011...) I assume his hub is welded on the front side to make a thread for the 2nd front bolt:

#4549

Posted 23 March 2019 - 10:15 PM

Sorry to clutter up Nev's topic, as this really deserves it's own thread...

Did some quick on-line modelling with a suspension calculator on scrub radius and wheel size on the Lotus chassis front.

(Not sure on the results, but the model figures looked OK to me. Numbers are within a few mm's...)

Started the modelling from the original front data:

Lotus Elise 111S (same front wishbones and steel hubs as our VX); 12°KPI with 185-55-15 ET14mm offset => +10.5mm scrub radius.

Standard VX220: 12°KPI with original 175-55-17 ET35mm offset => -16mm scrub radius. (That's what the tall narrow wheels do)

My VX220 on ATS DTC's: 12°KPI with 205-50-17 ET20mm offset => -2mm scrub radius.

Joshua's VX seem to have 16" Speedlines (ET26?): 12°KPI and assume 195-50-16 ET26mm offset => -5mm scrub radius.

Joshua's VX with 5°KPI and 15mm increased scrub radius => +10mm scrub radius. Which is exactly what Lotus has on the 111S... ![]()

Interesting results. Anybody with a decent suspension modeller here to look more into this??

Edited by Exmantaa, 23 March 2019 - 10:16 PM.

#4550

Posted 23 March 2019 - 11:39 PM

Edit; (because I drive quite low 40 series 888's on my VX front ![]() ):

):

- My VX220 on ATS DTC's: 12°KPI with 205-40-17 ET20mm offset => +2mm scrub radius.

Also had 45 series: 12°KPI with 205-45-17 ET20mm offset => 0mm scrub radius.

Interesting to see that the VX front is nowhere near the original Lotus specced +10mm positive scrub radius...

#4551

Posted 23 March 2019 - 11:55 PM

Hmmm, editing seems difficult.

I messed up the stock VX wheel offset [![]() ] )

] )

The stock VX wheels with the narrow tall 175-55-17 tires have ET26:

- Standard VX220: 12°KPI with original 175-55-17 ET26mm offset => -7mm scrub radius.

A bit less extreme result, but still interesting to see that the taller VX front tires are nowhere near the original Lotus specced +10mm positive scrub radius... ![]()

#4552

Posted 24 March 2019 - 11:12 AM

That’s some very useful info here 👠especially that Lotus specs more scrub radius than the VX. Perhaps GM wanted the VX to feel slighly more settled on the front end?

I read somewhere that one manufacturer specs a lot of negegative scrub on their cars because if the inside front wheel hits a large puddle at speed the car then steers out of the puddle.

My car has Compomotives with 205/60 26 and iirc my scrub on the standard set up was +5°.

Finally reducing the KPI from 7° to 5° made the VX feel a lot more eager on turn in and as I kept the caster and all other settings the same I put this down to increae in positive scrub.

How interesting to see another adaptation to the rear hub carrier. From that photo it looks like they have dropped the joint by about 9mm - which is all that can be done without machining the top of the hub carrier otherwise it fouls the wishbone.

I would guess they have indeed welded a threaded boss just below the original along side that new threaded seat. This mod would be so much easier if able to weld the hub carrier but I’m not sure how such a casting welds or how it might be affected? With this in mind I developed this arrangement using 10mm alloy steel.

Attached Files

#4553

Posted 24 March 2019 - 02:16 PM

That is an "interesting" hub attachment... ![]()

The Lotus hubs are not cast but a forged steel; 38MnVS6 DIN EN 10267 (There's a PDF on the net from the Lotus steel hub design.)

This steel should be OK to weld, but I have to ask a welding expert on the right specs.

Can you confirm your front size? Compomotives (Speedline 16' ET offset?) with 205/60/16??

PS; you have the Penske shocks?? ![]()

Edited by Exmantaa, 24 March 2019 - 02:18 PM.

#4554

Posted 25 March 2019 - 07:18 AM

If the lower wishbone location doesn't make much difference because of it's much longer length, would (almost) the same effect of lowering the top location on the upright not be reached by fitting uprights that have the axle center line moved up by the required amount?

Eg: https://www.elisepar...t-s2-rear-pair/

These have a 16mm raised axle line so in effect the top (and bottom) wishbones are moved down 16mm.

Of course this is (much) more expensive, so that can be a good reason to DIY (and that makes it easer to test stuff), but for a 'fit and forget' I'm just wondering it that would/should give the same result for the back? (or if you want to go even lower there's also a race/track one with a 40mm raise in the axle height if you want to run really low with the normal wishbone angles)

Bye, Arno.

#4555

Posted 25 March 2019 - 06:32 PM

Yep, off course the same (better) result can be achieved by fitting lowered GT or Race hubs on the rear... ($$$)

#4556

Posted 26 March 2019 - 10:38 AM

I may well stump up for gt hub carriers at some point but it would mean a redesign of mountings for the Porsche and mini handbrake calipers.

Wheels are Compomotive ET20 205/60/16 tyres.

Penske were fitted but they are off and I have Nitron 3 way waiting to go in, 40 front and 46 rear.

The canister pipes have been slightly extended so the canisters can be in the front and boot. I have designed a system using servo motors to adjust low and high speed bump from inside the cabin.

Machining for the front hub carrier.

Attached Files

#4557

Posted 26 March 2019 - 10:11 PM

Your 205/60/16 tyres on ET20 give a scrub radius of -4mm on unmodified hub & wishbones in my suspension modeller.

(Calculated from tire size deviations from the base 111S suspension model data and would be better if it can be measured.)

How did you come up with your original "+5°"? (= mm...)

#4558

Posted 29 March 2019 - 10:16 AM

Your 205/60/16 tyres on ET20 give a scrub radius of -4mm on unmodified hub & wishbones in my suspension modeller.

(Calculated from tire size deviations from the base 111S suspension model data and would be better if it can be measured.)

How did you come up with your original "+5°"? (= mm...)

Something I forgot to mention is my alloy bells add 6mm each side to the track so that’s effectively ET 14mm.

With the hub loaded and supported at approx correct height I traced a line down through the king pin pivot axis to a point on the floor and compared this to the centre line of the wheel. It was never going to be the most accurate absolute result but I could repeat the process to establish a pattern. Your model now predicts +2mm within 3mm of my measurement.

#4559

Posted 29 March 2019 - 11:47 PM

![]() (the modelling result is rough anyway, as it works with incremented values and I calculated everything with the theoretical tire heights.)

(the modelling result is rough anyway, as it works with incremented values and I calculated everything with the theoretical tire heights.)

But with an increase of +15mm from your mods you are now on +17/+20mm scrub radius?

Question is though if your better track feeling comes mostly from this increased scrub (which you can do much easier with some wheel spacers) or if the reduced KPI angle (reduced positive camber gain) also plays a major role in the result... ![]()

I will measure the real scrub angle on my car and if that is indeed near the calculated +2mm, I'll try what a pair of 10mm spacers does on my next track day. ![]()

#4560

Posted 02 April 2019 - 10:29 AM

I’ve been doing a bit of reading and it turns out manufacturers often use scrub as a tool in changing the feel of their cars. Earlier pre power steering 911s were known for their positive steering commonly having a scrub radius of around +25mm. Apparently the then concurrent Porsche 928 and 911 had similar front geometry except the 911 had notably positive and the 928 negative scrub reflecting the type of drivers expected to buy these cars.

So I think the improvement in grip is down to the reduction in KPI but the feeling of turn in eagerness is down to KPI and scrub.

The standard high KPI of 12° or so is more like that used on old school loose surface rally cars where the steering bias was towards returning to the centre to help catch tail slides. Perhaps that was Lotus thought with the Elise.

I understand there are wide track wishbones available. Does anyone know what dimension these are extended by? I’ve had the belated thought I might have been able to use the front uppers for this mod.

6 user(s) are reading this topic

0 members, 6 guests, 0 anonymous users