Alex I'll give you a ring once my slave cylinder turns up in the post (can't start anything till I get that)

![]()

Posted 06 June 2013 - 06:29 AM

Alex I'll give you a ring once my slave cylinder turns up in the post (can't start anything till I get that)

![]()

Posted 06 June 2013 - 09:39 PM

Engine is now timed up and dressed. Clutch slave cylinder has arrived in the post. Hopefully will get it up and running this weekend.

Posted 06 June 2013 - 09:45 PM

Love the colour coordination there.

Posted 06 June 2013 - 10:00 PM

Haha, yea, grimey red seems to be in fashion in my neck of the woods ![]()

Running without the floor-pan makes everything pretty dirty on the engine. It's certainly never going to be a concours winner that's for sure!

My clutch friction material is looking a bit thin after 8000 miles (even though I drive in a clutch friendly way). But it will have to do as I can't be arsed with waiting to send the plate off to Helix for new material to be put on it.

Posted 06 June 2013 - 10:22 PM

Was it quite an effort to swing it into the car?

Posted 07 June 2013 - 10:50 AM

Not hard at all really, those cranes are certainly worth the money. Mine has 4 big wheels on it, so fairly easy to move it about even with 200 KG swinging about on it. Also (amazingly for a £138 Chinese purchase) the crane hydraulics don't leak over time.

Posted 09 June 2013 - 07:26 PM

Alex (Ormes) very kindly came round today to spend 5 hours fitting the engine, box, pipes, etc back in the car with me. He did a stella job - thanyou Alex.

I am now left connecting up the dribs and drabs, and (just like last time 3 years ago), I have am completely stumped about where the plug that my 2 fingers are holding should plug into !! Help pls.

Posted 09 June 2013 - 07:29 PM

Posted 09 June 2013 - 07:37 PM

Lamdba sensor Nev?

Both connect onto the plate thats not yet fitted under your coil pack connection ![]()

Edited by MrSimba, 09 June 2013 - 07:41 PM.

Posted 09 June 2013 - 09:10 PM

No problem nev, any timethanyou Alex.

Or raffle tickets and selotapeA bit late this time, but next time.... Put a dymo label on each connector.... A to A, B to B etc

Posted 09 June 2013 - 09:14 PM

Posted 10 June 2013 - 07:15 AM

Lamdba sensor Nev?

Both connect onto the plate thats not yet fitted under your coil pack connection

Thats it - Lambda sensor plug, thanks Simon.

It would help if I bought some waterproof lables and attached them, might get on eBay now and buy some.

Can't wait to get home tonight after work and finish the job off. I have to mount the turbo, wastegate, exhaust, inlet pipework and couple of other little things. Hopefully it will burst back into life either tonight or tomorrow night.

Edited by Nev, 10 June 2013 - 07:26 AM.

Posted 13 June 2013 - 12:21 PM

I primed the oil and fuel systems the other night and little Nipper fired up first time like a good un. No EML, no issues at in fact, other than my brakes seem crap again.

This piston slap is only slight noticable at times as you drive about and is barely noticable if at all.

Thanks again to Alex, he must have saved me at least 3 hours of mucking about on both of his trips.

Edited by Nev, 13 June 2013 - 12:23 PM.

Posted 13 June 2013 - 06:09 PM

Fantastic ![]() Glad nipper lives and started the first time

Glad nipper lives and started the first time ![]() It is holding onto all of it's fluids?

It is holding onto all of it's fluids?

Posted 14 June 2013 - 07:33 AM

Yea, no drips what so ever (so far), though it's only been through 2 mild test/heat cycles, and nowhere the main powerband (6500 to 8000 RPM) yet which is where any leaks will show themselves.

Randy will be pleased to know that I've finally cut and rewelded the crank breather pipe so it's solid metal all the way to the cam cover ![]()

Rather irritatingly, the 1/4 inch NPT (male) oil pressure gauge I bought seems to have a different thread pitch to the 1/4 inch NPT (female) adapter it is meant to screw in to. Does anyone know what pitch these things are meant to be? 1.0 or 1.25 or what ? I need to know as I don't know which of the eBay sellers has sold me a non standard dud :o/

Edited by Nev, 14 June 2013 - 07:55 AM.

Posted 14 June 2013 - 08:03 AM

Nev, the main thing that stands out on the last couple of pages is that you haven't identified the drop in compression. I don't believe bore glazing is the cause of it, the contact between the ring and liner will still be as good as before the glazing occurred. One thing that sticks out is that if you have bore glazing you will likely have piston deposits and potentially ring stick. Do you have any photos of the pistons when they came out or description of the condition of the rings? Did you perform compression tests when the block was hot or cold?

Two other notes:

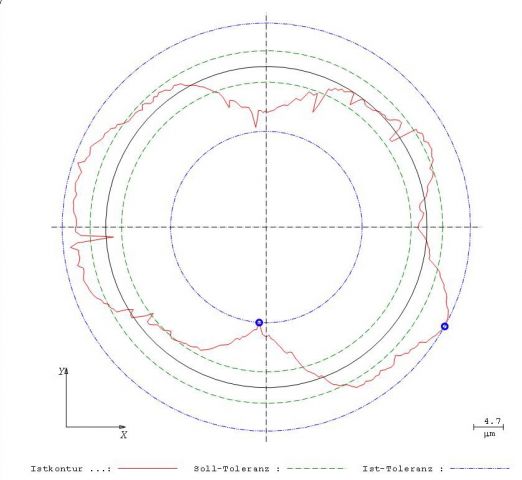

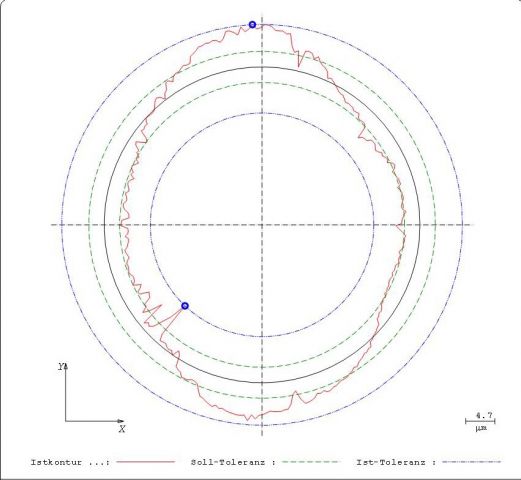

1. cylinder width isn't an accurate measurement of cylinder roundness. You can still have something which measures equal widths and still be deformed, no matter how many degrees around the cylinder you measure. You will need a 3D coordinate measurement to get a true idea of how round the cylinder is. To give you an idea of the significance of measuring a cylinder roundness under tension, these are the differences observed with a mystery engine with a similar construction to the Z20LET

roundness without gasket and head:

Roundness with gasket and head:

I'm sure you'll agree there is a big difference, therefore any measurement into roundness is irrelevant unless the block is under tension.

2. Bore glazing is unlikely to be due to overfueling, fuel is very clean these days - low sulfur, clean burning, so would not cause deposits. There are anti oxidants in oil which are known to cause glazing however, and it's likely that the untested, 'high performance' labelled oils have a lot in. I would strongly suggest running an oil with VW 504/507 claims which has a higher piston cleanliness requirement, specifically Mobil 1 ESP.

Posted 14 June 2013 - 08:34 AM

Rather irritatingly, the 1/4 inch NPT (male) oil pressure gauge I bought seems to have a different thread pitch to the 1/4 inch NPT (female) adapter it is meant to screw in to. Does anyone know what pitch these things are meant to be? 1.0 or 1.25 or what ? I need to know as I don't know which of the eBay sellers has sold me a non standard dud :o/

I assume it screws in only a little and then 'binds'? That's normal for an NPT thread as it's a tapered male end where the female side is often not tapered or less so.

As a result it usually screws in by hand about 3 to 4 turns and then takes another 1 to 2 turns with a spanner to fully tighten. Don't over-tighten as it can split..

As it's a pipe-thread it should self-seal somewhat, but I usually coat the threads with a little Hylomar blue (if it needs to be taken apart more often) or some mild loctite thread sealant.

Bye, Arno.

Posted 14 June 2013 - 09:41 AM

Thanks Arno, thats exactly the problem I faced. I will attempt to force the male into the female tonight and use a bit of locktight.

Fez, the pistons have been replaced, and bores re-honed, oil changed. The guy who does my boring would be highly unlikely to have a fancy press to compress the block into whist reboring I think.

It's all a bit accademic now, as the engine no longer smokes. I do think fuel was in the oil (by smell test). I intend to change the oil more often (and hopefully) buy a new ECU + remap.

I am stumped with the compression test results TBH. Might have read low due to my crap guage. All tests were done cold BTW, some after the engine was standing still for 2 weeks. I might get round to re-test with the new engine if I can find time.

I still have my old pistons in a box. The base of their skirts was worn, however the rings and ringlands were all fine (visually).

Edited by Nev, 14 June 2013 - 09:45 AM.

Posted 14 June 2013 - 12:30 PM

Sorry Nev, but......fnaaaarI will attempt to force the male into the female tonight

Posted 14 June 2013 - 12:37 PM

Sorry Nev, but......fnaaaarI will attempt to force the male into the female tonight

and also...

Don't over-tighten as it can split..

0 members, 2 guests, 0 anonymous users