Nev, lots of places bore engines with a deck plate to tension it. Its nothing too fancy. I'll see if I can find a picture for you.

ETA:

Edited by FLD, 14 June 2013 - 12:42 PM.

Posted 14 June 2013 - 12:40 PM

Nev, lots of places bore engines with a deck plate to tension it. Its nothing too fancy. I'll see if I can find a picture for you.

ETA:

Edited by FLD, 14 June 2013 - 12:42 PM.

Posted 14 June 2013 - 12:45 PM

Sorry Nev, but......fnaaaarI will attempt to force the male into the female tonight

Ooops !

Posted 14 June 2013 - 12:47 PM

Nev, lots of places bore engines with a deck plate to tension it. Its nothing too fancy. I'll see if I can find a picture for you.

ETA:

Hmm, interesting and rather simple too, just bolt on a dummy cylinder head. Didn't know about this being common practice.

Posted 14 June 2013 - 12:52 PM

I perhaps should have qualified....common in V8 land. Most of my tinkerings have been 1/4 milers so SBC/BBC/LSx. I can only go on my experience.

Posted 14 June 2013 - 12:56 PM

It's expensive to do but worth it. JLR saved one million by moving away from it, but back when Aston Martin were using their engines they would rebore with a deck plate in place.

Posted 14 June 2013 - 02:37 PM

JLR still make the V8 for Aston Martin. The V12 is made at an Aston Martin plant in GermanyIt's expensive to do but worth it. JLR saved one million by moving away from it, but back when Aston Martin were using their engines they would rebore with a deck plate in place.

Posted 22 June 2013 - 06:22 AM

Nev, the main thing that stands out on the last couple of pages is that you haven't identified the drop in compression. I don't believe bore glazing is the cause of it, the contact between the ring and liner will still be as good as before the glazing occurred. One thing that sticks out is that if you have bore glazing you will likely have piston deposits and potentially ring stick. Do you have any photos of the pistons when they came out or description of the condition of the rings? Did you perform compression tests when the block was hot or cold?

Two other notes:

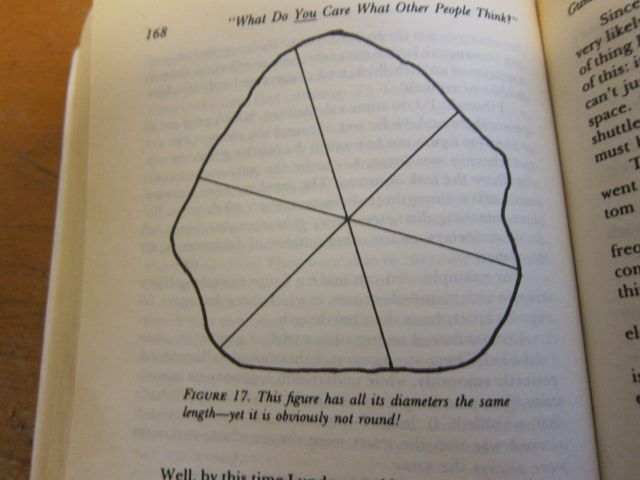

1. cylinder width isn't an accurate measurement of cylinder roundness. You can still have something which measures equal widths and still be deformed, no matter how many degrees around the cylinder you measure. You will need a 3D coordinate measurement to get a true idea of how round the cylinder is. To give you an idea of the significance of measuring a cylinder roundness under tension, these are the differences observed with a mystery engine with a similar construction to the Z20LET

roundness without gasket and head:

Roundness with gasket and head:

I'm sure you'll agree there is a big difference, therefore any measurement into roundness is irrelevant unless the block is under tension.

2. Bore glazing is unlikely to be due to overfueling, fuel is very clean these days - low sulfur, clean burning, so would not cause deposits. There are anti oxidants in oil which are known to cause glazing however, and it's likely that the untested, 'high performance' labelled oils have a lot in. I would strongly suggest running an oil with VW 504/507 claims which has a higher piston cleanliness requirement, specifically Mobil 1 ESP.

I have seen enough cylinder bores to know bore wash when I see it, you get a crazed effect in some areas on the bore wall and in Nev's case you could still see most of the honing marks meaning that the bores had not yet run in.

I do not see what the fuel content has to do with bore washing (unless methanol) this was caused by too much fuel (un-burnt), no special oil will cure that, only re-mapping will fix the problem.

The bores were measured with a deck plate in place so the block was under tension.

The piston skirt area on the pistons which came out hade worn excessively due to the excess fuel reducing the lubricating properties of the oil.

The chrome face of the top piston ring on each piston was either worn or missing which I have seen before in an engine with bore wash.

Steve

Posted 22 June 2013 - 07:24 AM

lol, this thread makes for hard reading! I must try harder to understand wat you guys are on about ![]() interesting though

interesting though ![]()

Posted 22 June 2013 - 07:53 AM

I do not see what the fuel content has to do with bore washing (unless methanol) this was caused by too much fuel (un-burnt), no special oil will cure that, only re-mapping will fix the problem.

The bores were measured with a deck plate in place so the block was under tension.

The piston skirt area on the pistons which came out hade worn excessively due to the excess fuel reducing the lubricating properties of the oil.

The chrome face of the top piston ring on each piston was either worn or missing which I have seen before in an engine with bore wash.

Steve

Well here in lies the problem, you state no special oil can cure that they say fuel has reduced the lubricating properties of the oil, this is incorrect. We can cure this problem by adding what are called boundary additives in treat rates as low at 0.1 % of the final oil which can take catastrophically failing oils which suffer from high piston skirt, liner and high bore wear to making them look like new. These additives bind to the rubbing surfaces and provide lubrication even when the oil is too thin to provide lubrication.

The fuel content was mentioned because normal fuel has greater lubricating properties than ultra low sulfur fuel and much greater lubricating properties than higher ethanol fuel (which most high octane fuel contains).

Measuring the bores with a deck plane is meaningless unless you are taking a 2d coordinate measurement, simply measuring diameter does not show distorted bores.

Posted 22 June 2013 - 09:09 AM

Man knows oil.

Posted 22 June 2013 - 08:04 PM

I do not see what the fuel content has to do with bore washing (unless methanol) this was caused by too much fuel (un-burnt), no special oil will cure that, only re-mapping will fix the problem.

The bores were measured with a deck plate in place so the block was under tension.

The piston skirt area on the pistons which came out hade worn excessively due to the excess fuel reducing the lubricating properties of the oil.

The chrome face of the top piston ring on each piston was either worn or missing which I have seen before in an engine with bore wash.

Steve

Well here in lies the problem, you state no special oil can cure that they say fuel has reduced the lubricating properties of the oil, this is incorrect. We can cure this problem by adding what are called boundary additives in treat rates as low at 0.1 % of the final oil which can take catastrophically failing oils which suffer from high piston skirt, liner and high bore wear to making them look like new. These additives bind to the rubbing surfaces and provide lubrication even when the oil is too thin to provide lubrication.

The fuel content was mentioned because normal fuel has greater lubricating properties than ultra low sulfur fuel and much greater lubricating properties than higher ethanol fuel (which most high octane fuel contains).

Measuring the bores with a deck plane is meaningless unless you are taking a 2d coordinate measurement, simply measuring diameter does not show distorted bores.

No idea what a deck plane is.

When a deck plate is used with a bore micrometer you can measure the distortion before and after torquing down the deck plate.

Measurements taken at at several angles and several heights, very easy to see the difference.

If I was building an F1 engine I would use better more expensive measuring methods.

Perhaps I should word the excess fuel problem different, the excess fuel washes the oil from the bores, in Nev's case piston wear and also caused the bores to be polished also damaging the chrome face of the top piston rings.

It was known to be running rich (too much fuel) as the CO was off the scale.

The lubricating properties of fuel I understood to refer to valve seat and valves, please tell me more.

Steve

Posted 22 June 2013 - 08:46 PM

Steve, refer to the Space shuttle challenger disaster - one contributing factor was the diameter measurement they used when reattaching cylindrical section which made up the rockets, they measured the diameter using a central point and assumed that when equal, they would be round. This is not correct. As I stated, only a 2d coordinate measurement will actually identify if it is round. See photo from investigation extract:

CO reading when not running a cat is a pointless measurement, certainly not an indication of rich running. Boundary lubrication will not be 'washed off', therefore my oil suggestion is still valid. Fuel lubrication isn't just valve seats, includes fuel pumps -refer to early 90's which diesel switched from high sulfur to low, many older cars had serious fuel pump lubrication issues which made additive companies, including the one I work for, very rich generating solutions. We have also managed to change cylinder wear engine tests from failing to passing by changing the fuel type, it's sensitive to ethanol content and summer/winter fuel grades.

Edited by fezzasus, 22 June 2013 - 08:49 PM.

Posted 22 June 2013 - 08:57 PM

Steve, refer to the Space shuttle challenger disaster.......

![]()

![]()

![]()

![]()

![]()

Posted 22 June 2013 - 09:00 PM

Steve, refer to the Space shuttle challenger disaster.......

I know, ridiculous example, but it's clearly bad practice to be using the same measurement technique as something proven to contribute to the disaster.

Posted 22 June 2013 - 09:04 PM

Steve, refer to the Space shuttle challenger disaster.......

Best example for anything ever. Brilliant

Posted 22 June 2013 - 09:51 PM

Steve, refer to the Space shuttle challenger disaster - one contributing factor was the diameter measurement they used when reattaching cylindrical section which made up the rockets, they measured the diameter using a central point and assumed that when equal, they would be round. This is not correct. As I stated, only a 2d coordinate measurement will actually identify if it is round. See photo from investigation extract:

CO reading when not running a cat is a pointless measurement, certainly not an indication of rich running. Boundary lubrication will not be 'washed off', therefore my oil suggestion is still valid. Fuel lubrication isn't just valve seats, includes fuel pumps -refer to early 90's which diesel switched from high sulfur to low, many older cars had serious fuel pump lubrication issues which made additive companies, including the one I work for, very rich generating solutions. We have also managed to change cylinder wear engine tests from failing to passing by changing the fuel type, it's sensitive to ethanol content and summer/winter fuel grades.

You are missing the point Nev's engine is mapped so rich you do not even need a CO meter to tell.

I think it was the Lotus Esprit that could pass most emission legislation without a cat.

Like I said if I was building an F1 engine or in your case a space shuttle I would use a more accurate method to measure bore distortion.

I do know about fuel lubrication I have a car fitted with a Ford 2.0 BDG fitted with 8mm Lucas mechanical fuel injection.

Steve

Posted 23 June 2013 - 07:51 AM

Fezz you should teach or something. Even for dumfucks like me you make complex answers easy to understand.I know, ridiculous example, but it's clearly bad practice to be using the same measurement technique as something proven to contribute to the disaster.

Steve, refer to the Space shuttle challenger disaster.......

Posted 24 June 2013 - 12:08 PM

Can anyone near(ish) to Bristol help me out by switching my bloody airbag light off pls? I have tried OpCom on both my laptop and Jeremy's (Hairy), but different errors with both of them.

Honstly, this problem is driving me mad, any help with a working laptop/software/lead kindly accepted...

Posted 25 June 2013 - 08:48 PM

Christ alive these cars are quick, the difference from my Ford TDCi is just insane. ![]()

Posted 25 June 2013 - 09:10 PM

0 members, 3 guests, 0 anonymous users