Project Jerusalem

#181

Posted 01 October 2011 - 11:57 AM

#182

Posted 01 October 2011 - 12:12 PM

Where are mine

Will order next week

#183

Posted 04 October 2011 - 11:42 PM

Edited by Stuwy, 04 October 2011 - 11:43 PM.

#184

Posted 05 October 2011 - 06:39 AM

#185

Posted 07 October 2011 - 06:25 PM

Take one VX220 wishbone. Cover in hammerite paint and bake in heated shed for 8hrs.

Make sure inside edge of wishbone is completely clean.

Remove rose joints from freezer

Place bolt and applicator in from the bottom and align the rose joint to top (not visible in pic)

Place the top of the applicator on the rose joint with a nut and wind it finger tight

Using utensils now tighten so that rose joint is aligned and pulled into wishbone correctly

Continue to stir until applicator tool is completely tight againt wishbone.

Rose joint is now inserted to the correct depth

#186

Posted 07 October 2011 - 06:25 PM

Push spacer into rose joint

Turn wishbone over and pack full of grease again

Push in spacer and oring

Now go and do the rest

Next up PIZZA

#187

Posted 07 October 2011 - 06:36 PM

#188

Posted 07 October 2011 - 06:43 PM

Quick question...

Why use a rose joint in the wishbone ends? Would it not be more sensible to be using a roller bearing?

Nah wrong application. Short stroke applications like this use rose joints for the optimum load bearing. Roller type bearings are used for something that would continue to rotate like a wheel for instance. They cannot sustain the amount of load a rose joint can.

I think

#189

Posted 07 October 2011 - 06:53 PM

Quick question...

Why use a rose joint in the wishbone ends? Would it not be more sensible to be using a roller bearing?

Nah wrong application. Short stroke applications like this use rose joints for the optimum load bearing. Roller type bearings are used for something that would continue to rotate like a wheel for instance. They cannot sustain the amount of load a rose joint can.

I think

I guess thats why I'm a scientist and not an engineer. I'd have put a twin taper roller bearing in it!

#190

Posted 07 October 2011 - 09:31 PM

Quick question...

Why use a rose joint in the wishbone ends? Would it not be more sensible to be using a roller bearing?

Nah wrong application. Short stroke applications like this use rose joints for the optimum load bearing. Roller type bearings are used for something that would continue to rotate like a wheel for instance. They cannot sustain the amount of load a rose joint can.

I think

I guess thats why I'm a scientist and not an engineer. I'd have put a twin taper roller bearing in it!

atom's & formula one cars use twin taper roller bearing.load force has a wider distribution but maintenance is higher

therefore not practical for cars owed by non scientist or engineers

#191

Posted 08 October 2011 - 07:06 AM

#192

Posted 08 October 2011 - 08:39 AM

you need to get those wishbones powder coated Jimmy

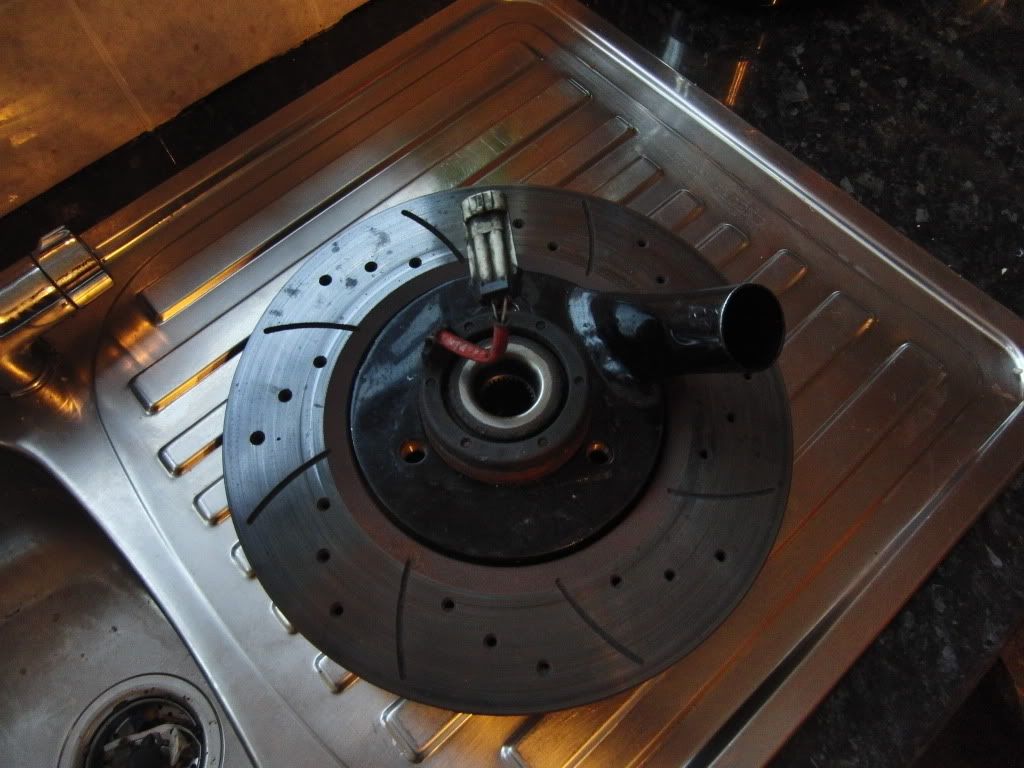

Also you need a bigger workshop/shed.Your balls are going to strung up shortly if you leave brake bits on the sink

She wasn't happy when she got in and saw her kitchen had been taken over

#193

Posted 08 October 2011 - 08:43 AM

Edited by FLD, 08 October 2011 - 08:44 AM.

#194

Posted 08 October 2011 - 08:46 AM

Quick question...

Why use a rose joint in the wishbone ends? Would it not be more sensible to be using a roller bearing?

Nah wrong application. Short stroke applications like this use rose joints for the optimum load bearing. Roller type bearings are used for something that would continue to rotate like a wheel for instance. They cannot sustain the amount of load a rose joint can.

I think

I guess thats why I'm a scientist and not an engineer. I'd have put a twin taper roller bearing in it!

atom's & formula one cars use twin taper roller bearing.load force has a wider distribution but maintenance is higher

therefore not practical for cars owed by non scientist or engineers

Good to know I'm not a complete retard then! I cant wait to see your car rolling. It will be awesome.

#195

Posted 08 October 2011 - 02:34 PM

#196

Posted 08 October 2011 - 06:40 PM

Are you racing your car next year Jimmy, just tracking it, or turning it back into a road car ?

Oh it'll never go back Nev

Plan is to race

#197

Posted 15 October 2011 - 08:51 PM

So got my bits today and did a chunk more work

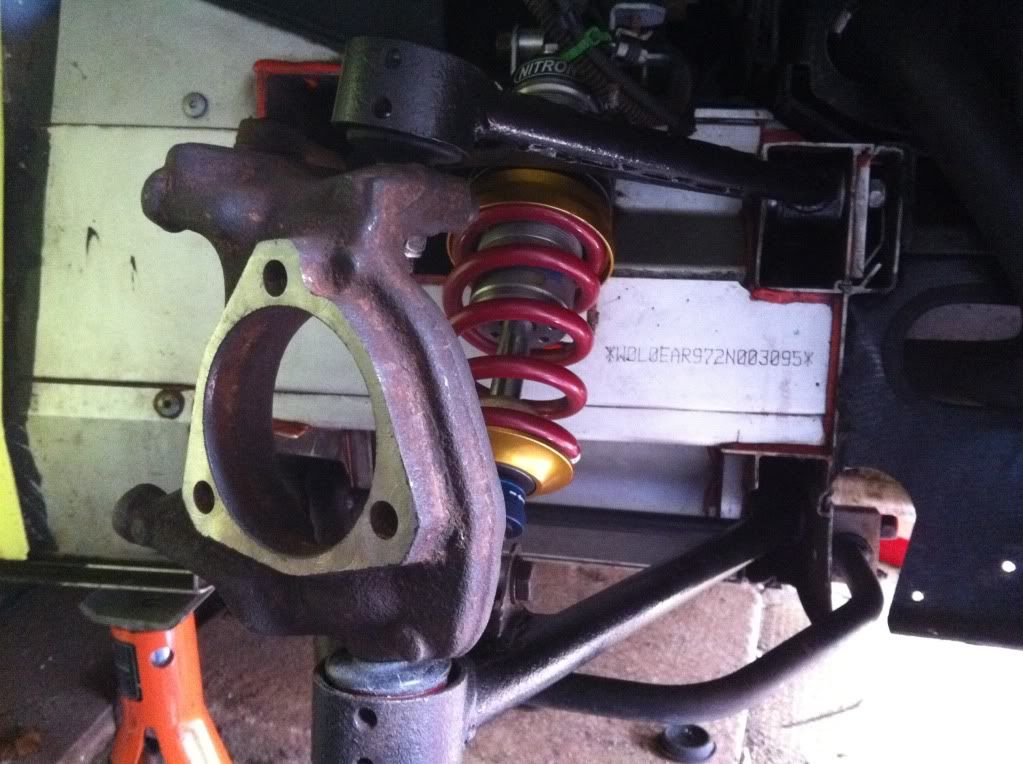

Hub machined on the main face too to centralise the brake disc and to add more neg camber. Castor also maximised.

Front right wishbone fully finished now with new ball joints, new wishbone bushes, machined hub, brake cooling duct

ABS is coming out soon, have to do the passenger side of the car next though, but have to take a trip to the big A first for some aero mods!

#198

Posted 15 October 2011 - 08:55 PM

#199

Posted 15 October 2011 - 09:33 PM

How much clearance is the brake duct and pipe work going to have from the Nitrons Jim? Full lock left/right would it not rub?

Nah there's plenty of clearance dude, this is quite a common mod tbh

#200

Posted 15 October 2011 - 09:54 PM

2 user(s) are reading this topic

0 members, 2 guests, 0 anonymous users