Project Jerusalem

#481

Posted 14 November 2012 - 10:58 AM

#482

Posted 14 November 2012 - 11:16 AM

Don't think so Steve

re: charcoal canister , does the PA fuel tank have a different vent system , otherwise won't you get problems

how does it work then, there must be a one way valve to allow air in to the tank as fuel is used up. I though this was all part of the charcoal canister plus a vacuum solenoid control to the plenum.

#483

Posted 14 November 2012 - 11:34 AM

#484

Posted 14 November 2012 - 11:45 AM

#485

Posted 14 November 2012 - 01:00 PM

JG, you should make a kit for us lot going 044 and swirl pot.

Trouble is everyone is doing it slightly differently at the moment. Those that have PA tanks dont need Swirl pots in my view. I havent managed to get fuel starvation no matter how hard i try since the PA tank was fitted.

Then you have the option of going from the fuel rail back to the fuel filter, a nice tidy up on the lines around the SC (thats how yours and mine are at the moment) or going from the rail, right the way back to the tank (which i think is the best option). With harrops which are even closer to the bulk head, moving the the lines is even more important.

I'm going to do Lee's at some point when fitting a PA tank, and go right the way back to the tank with AN lines. Oddly, there are more or less the same number of fittings going all the way back to the tank than as there are going back to the filter. So the cost is roughtly the same which ever option you chose (apart from an expensive filter from sytec, which Jimmy and I speced, actually the original spec came from Mike (rallye)

I can help get fittings, filters, braided hose at quite a significant discount

#486

Posted 14 November 2012 - 01:01 PM

for simplicity I am tempted to delete the fuel return = half as many fitting / hoses so cost saving

What won't work. Pumps by their very nature, need a flow rate to work. If you stop the flow rate you stop the pump. .

#487

Posted 14 November 2012 - 01:02 PM

#488

Posted 14 November 2012 - 01:03 PM

for simplicity I am tempted to delete the fuel return = half as many fitting / hoses so cost saving

What won't work. Pumps by their very nature, need a flow rate to work. If you stop the flow rate you stop the pump. .

#489

Posted 14 November 2012 - 01:05 PM

Lsj doesn't have a return on the fuel rail

for simplicity I am tempted to delete the fuel return = half as many fitting / hoses so cost saving

What won't work. Pumps by their very nature, need a flow rate to work. If you stop the flow rate you stop the pump. .

#490

Posted 14 November 2012 - 01:08 PM

The issue on the Harrop is not fuel surge JG, we simply run out of rail pressure even on the uprated pumps and anything over 330BHP requires an external Bosch 044 and swirl pot.

Can't the 044 be fitted in the tank:

#491

Posted 14 November 2012 - 01:08 PM

Lsj doesn't have a return on the fuel rail

for simplicity I am tempted to delete the fuel return = half as many fitting / hoses so cost saving

What won't work. Pumps by their very nature, need a flow rate to work. If you stop the flow rate you stop the pump. .

So where does the unused fuel go?

#492

Posted 14 November 2012 - 01:08 PM

Lsj doesn't have a return on the fuel rail

for simplicity I am tempted to delete the fuel return = half as many fitting / hoses so cost saving

What won't work. Pumps by their very nature, need a flow rate to work. If you stop the flow rate you stop the pump. .

It must do, or it has a diffent set-up elesewhere. the pump can't provide a presure without a flowrate.

#493

Posted 14 November 2012 - 01:10 PM

Edited by leevx2.2, 14 November 2012 - 01:11 PM.

#494

Posted 14 November 2012 - 01:13 PM

That's why we can't find a use for it as we thought the same :-s

Lsj doesn't have a return on the fuel rail

for simplicity I am tempted to delete the fuel return = half as many fitting / hoses so cost saving

What won't work. Pumps by their very nature, need a flow rate to work. If you stop the flow rate you stop the pump. .

It must do, or it has a diffent set-up elesewhere. the pump can't provide a presure without a flowrate.

#495

Posted 14 November 2012 - 01:36 PM

It doesn't joe has got a LSj fuel rail in his garage not on car and only has one fuel line into it no return

Odd. B207R has a return. Or two inlets.

#496

Posted 14 November 2012 - 01:59 PM

Next job was injectors and the fuel lines. The LSJ normally has a non-return fuel rail, but I fitted the Z22SE rail as I will later map it with a boost referenced return system. Injectors are 42lb's; standard requirement for a GM stage 2 mapping. I already had bought some high pressure fuel hose (J30R9+ spec), so re-routing the fuel hoses was next. The rail connections need some serious modding for this and after that was ready i finished with the dual pass cooler connections. (Just a temporary set-up for now, as I still need to mount the pre-rad up front with the sill hoses):

#497

Posted 14 November 2012 - 02:17 PM

#498

Posted 14 November 2012 - 02:22 PM

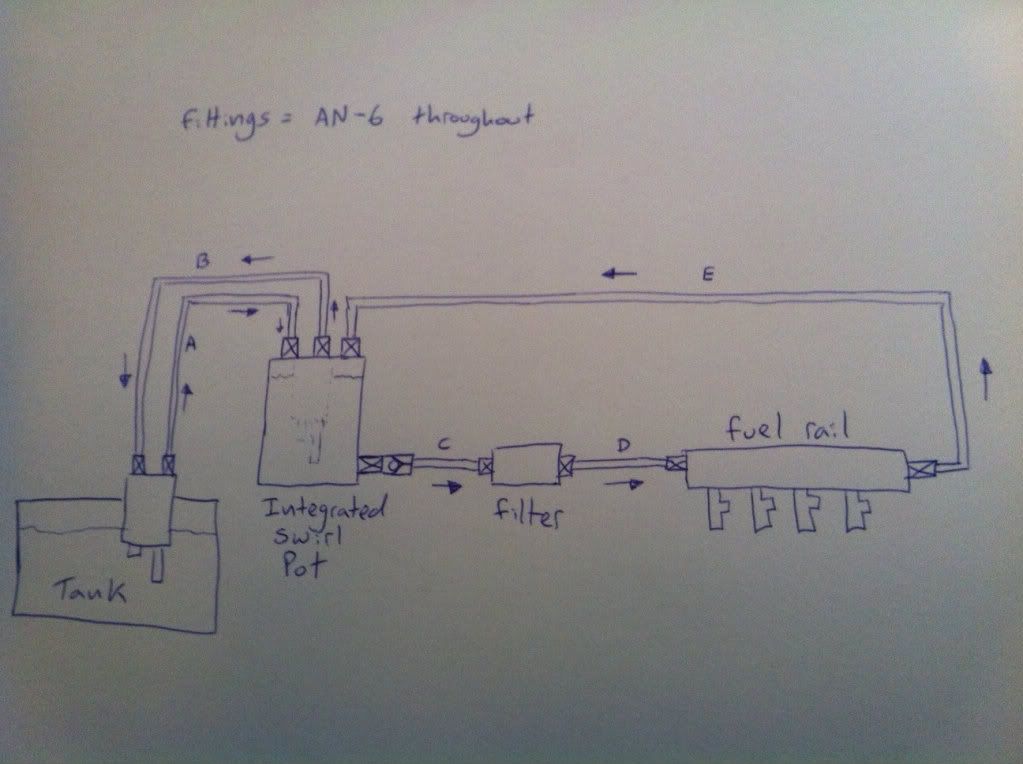

I've got a whole seperate thread on this HERE, but here's a drawing of what I went for. Note the hose A has a filter in it too (main Sytec filter) to protect my 044 then a smaller filter to protect the rail in case then044 fails.

For the record if you are looking at a swirl pot then you really need to run with one low pressure pump in the tank and one high pressure pump to feed rail. Standard and the popular Sytec pumps are high pressure.

Also for ease of mounting I bought a swirl pot within which I could mount my 044. Pricey but very well made!!!

http://www.intengine...d-044-pump.html

#499

Posted 14 November 2012 - 02:30 PM

#500

Posted 14 November 2012 - 02:47 PM

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users