Same experience here. Does the wiki space need funding? Could a mod explain for us please?Subscription Expired[color=rgb(51,51,51);]

This wiki's subscription has expired. The wiki will be reactivated once one of the wiki organizers renews the wiki's subscription. For more information, please visit this blog post.[/color][color=rgb(51,51,51);]

[/color][color=rgb(51,51,51);]

(On the VX220 wiki site, wanted to have a read about replacing the pump)[/color]

Fuel Pump Replacement Guide

#61

Posted 17 April 2016 - 09:59 PM

#62

Posted 18 April 2016 - 02:28 PM

Same experience here. Does the wiki space need funding? Could a mod explain for us please?Subscription Expired

[color=rgb(51,51,51);][font="'Helvetica Neue';"]This wiki's subscription has expired. The wiki will be reactivated once one of the wiki organizers renews the wiki's subscription. For more information, please visit this blog post.[/color][/font]

[color=rgb(51,51,51);][font="'Helvetica Neue';"] [/color][/font]

[color=rgb(51,51,51);][font="'Helvetica Neue';"](On the VX220 wiki site, wanted to have a read about replacing the pump)[/color][/font]

Was never anything to do with us/.org. From memory, the "guide" was just a pdf version of Vocky's original post and the whole thing barely contained anything of any use and the SELOC wiki probably has more useful stuff.

#63

Posted 19 April 2016 - 07:45 PM

Aahh, sorry. Understood.

#64

Posted 12 March 2017 - 02:30 PM

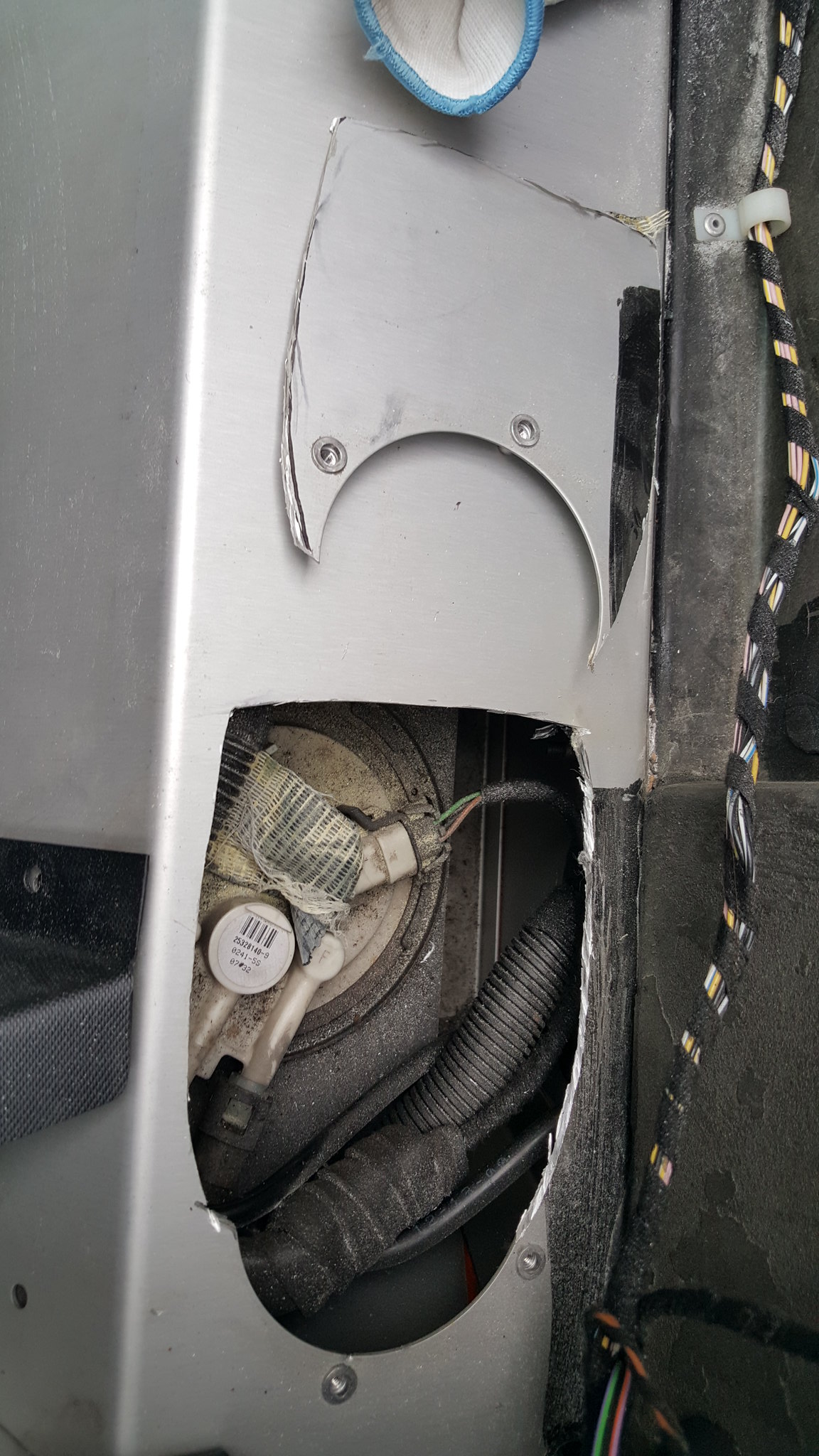

Not sure where I should begin making this bigger, seat belt is in the way and welded to the roll bar. What do you think is the recommenced battery powered tool that won't end up with my car on fire? I have no power supply.

20170312_130615 by Richard Fanders, on Flickr

20170312_130615 by Richard Fanders, on Flickr

20170312_130621 by Richard Fanders, on Flickr

20170312_130621 by Richard Fanders, on Flickr

#65

Posted 12 March 2017 - 02:34 PM

What is the point in a fuel pump inspection hatch that's not big enough. ![]()

#66

Posted 12 March 2017 - 03:11 PM

Seatbelt casing is not welded to the rollbar.

Lay your head sideways where those 4 screws are lying.

You will see a large bolt. (Use a flashlight)

Edited by smiley, 12 March 2017 - 03:13 PM.

#67

Posted 12 March 2017 - 03:29 PM

#68

Posted 12 March 2017 - 03:41 PM

I used a dremel, but that's because it was all i had.

#69

Posted 12 March 2017 - 03:47 PM

#70

Posted 12 March 2017 - 05:51 PM

measure twice and cut once, do not go too close to the edge.

#71

Posted 12 March 2017 - 05:55 PM

something like this

#72

Posted 12 March 2017 - 06:14 PM

#73

Posted 18 March 2017 - 10:43 AM

#74

Posted 18 March 2017 - 12:17 PM

what sparks? ![]()

just take your inertia reel off and then the cover and just feel underneath for where the loom is, they tape it to the underside and sometimes its right were you need to cut.

try drilling holes on the corners and cut up to the holes, make it neater and for what its worth probably stronger than 90degree cuts.

jam a rag in there before cutting so the swarf doesnt go everywhere.

Edited by chris_uk, 18 March 2017 - 12:18 PM.

#75

Posted 18 March 2017 - 12:19 PM

#76

Posted 18 March 2017 - 12:36 PM

#77

Posted 18 March 2017 - 01:42 PM

it would if it was steel, but its aluminium so no sparks ![]()

#78

Posted 18 March 2017 - 01:43 PM

#79

Posted 18 March 2017 - 01:47 PM

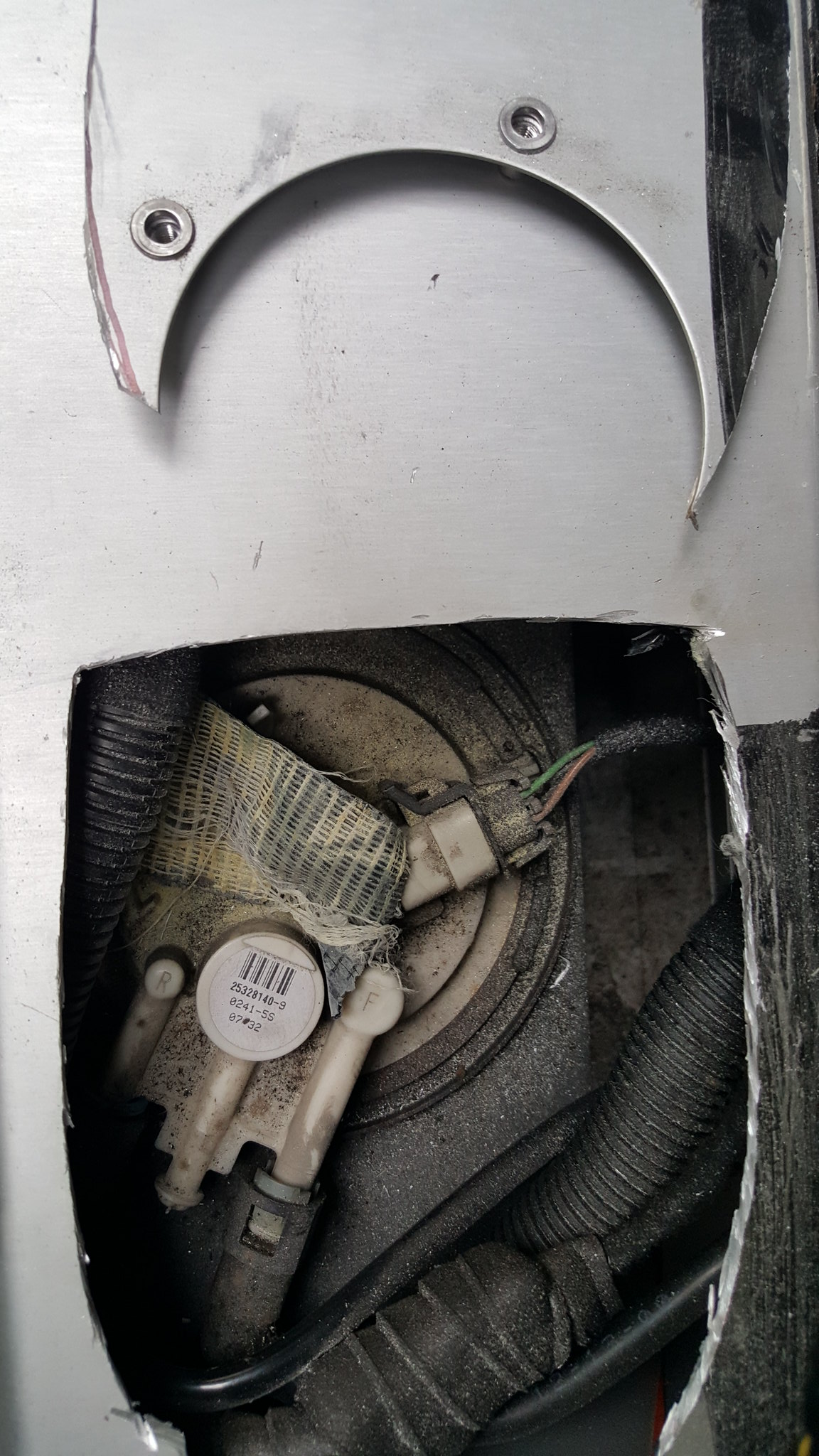

There are no pump installed pictures on this thread anymore so I'm struggling to figure out the circlip.

First time I've used a dremel, I know it's not tidy

20170318_130446 by Richard Fanders, on Flickr

20170318_130446 by Richard Fanders, on Flickr

20170318_131709 by Richard Fanders, on Flickr

20170318_131709 by Richard Fanders, on Flickr

20170318_132350 by Richard Fanders, on Flickr

20170318_132350 by Richard Fanders, on Flickr

20170318_133913 by Richard Fanders, on Flickr

20170318_133913 by Richard Fanders, on Flickr

20170318_133922 by Richard Fanders, on Flickr

20170318_133922 by Richard Fanders, on Flickr

#80

Posted 18 March 2017 - 01:58 PM

when i said drill holes, i kinda meant 10mm ones.

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users