When I get home Nick I'll send you my basket at Summit Racing which is where I'm ordering almost all of the fixings from and you can work out what you need extra as you might need a couple more due to your swirl pot.

Full Conversion Of Oe Fuel Hoses To AN/JIC

#21

Posted 08 September 2011 - 09:32 AM

#22

Posted 08 September 2011 - 10:10 AM

#23

Posted 09 September 2011 - 09:53 AM

#24

Posted 09 September 2011 - 03:56 PM

#25

Posted 10 September 2011 - 07:51 AM

I've been having a look and debating whether it is worth swapping them.

The plastic OEM lines as far as I am aware last forever, whereas I've seen several mentions of aftermarket hose perishing and leaking.

Perhaps the safest solution is to encase the lines in something solid around the SC belt area? It may not be the neatest but what are your thoughts?

I'm also thinking in going that route. I don't see me changing al the fuel lines at this point so I had the idea of pulling a braided hose over the existing fuel lines near the SC belt.

*edit* Something like this: http://www.ebay.co.u...d#ht_1872wt_905

Edited by Denthrax, 10 September 2011 - 07:58 AM.

#26

Posted 07 February 2012 - 07:53 AM

#27

Posted 07 February 2012 - 01:27 PM

I bought the fuel rail adapters which turned up last week but I haven't had a chance to do anything with it yet. I have Aeroquip hose going to the rail already, just need to change the ends once I've decided between 90 or 120 deg fittings. I suspect I will end up working backwards towards the tank replacing everything.

#28

Posted 07 February 2012 - 04:38 PM

#29

Posted 08 February 2012 - 07:24 AM

#30

Posted 22 February 2012 - 08:10 PM

#31

Posted 22 February 2012 - 08:21 PM

#32

Posted 27 February 2012 - 10:08 PM

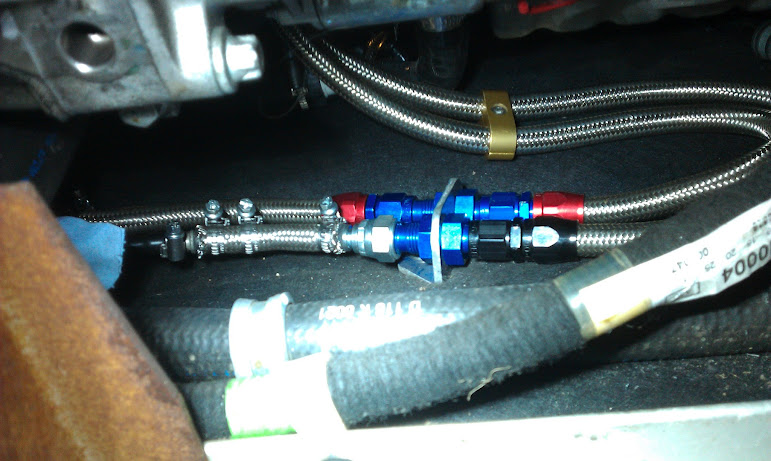

The other end of the hoses look like this:

The bracket keeps the hose onto the fuel filter pipe under compression so the worse that can happen is a bit of seepage rather than the hose blowing off entirely. Note the use of double jubilee clips too!

Now that I know you can get converters to fit the pump housing I'm sure I'll replace the rest of the system with compression fittings... probably when I fit the Proalloy fuel tank

#33

Posted 28 February 2012 - 12:08 PM

#34

Posted 28 February 2012 - 12:20 PM

#35

Posted 28 February 2012 - 02:33 PM

#36

Posted 05 March 2012 - 01:17 PM

#37

Posted 05 March 2012 - 01:44 PM

#38

Posted 05 March 2012 - 03:44 PM

#39

Posted 05 March 2012 - 04:20 PM

"For war zones like Vietnam the US military required a range of strong, light, high temperature hose assemblies that could be serviced in the field for use in oil, fuel and hydraulic applications, mainly on helicopters... This hose has AQP elastomer tube, partial stainless steel inner braid and a full stainless steel outer braid reinforcement."

It has a rated working pressure of 1000psi and a burst pressure of 6000psi so more than capable of handling fuel injection

#40

Posted 01 July 2012 - 10:24 AM

http://www.summitrac...rts/RUS-640850/

http://www.summitrac...rts/RUS-640860/

I'm about to place an order for these, postage is on the expensive side of expensive, so if anyone else would like a set, shout now.

Currently i'm ordering two sets.

2 user(s) are reading this topic

0 members, 2 guests, 0 anonymous users